Components of CNC EDM machine tools and their functions

Components of CNC EDM machine tools and their functions. The most commonly used in CNC EDM machines are EDM perforation, forming processing machines.

It includes the main body of the machine tool, pulse power supply, servo feed system, working fluid circulation system and machine tool accessories, as shown in the figure.

(1) The main body of the machine tool

The main machine consists of bed, spindle, table and lubrication system. It is mainly used to support tools and workpiece electrodes, ensure the discharge gap between them, and realize stable feed movement during processing.

CNC lathes are controlled by stepper motors

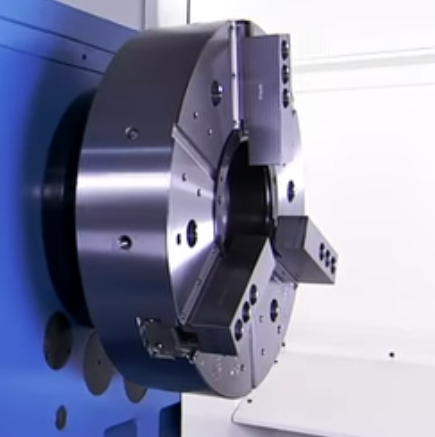

◆ Bed and column

The bed and column are the main part of the machine tool, which can ensure the relative position of the table and the tool electrode and the workpiece electrode, and its accuracy will directly affect the processing quality. Generally, the bed is a box structure with good rigidity, and the column is firmly fixed on the joint surface of the bed, and the spindle box is installed on the front surface of the column. The entire machine has a C-shaped structure.

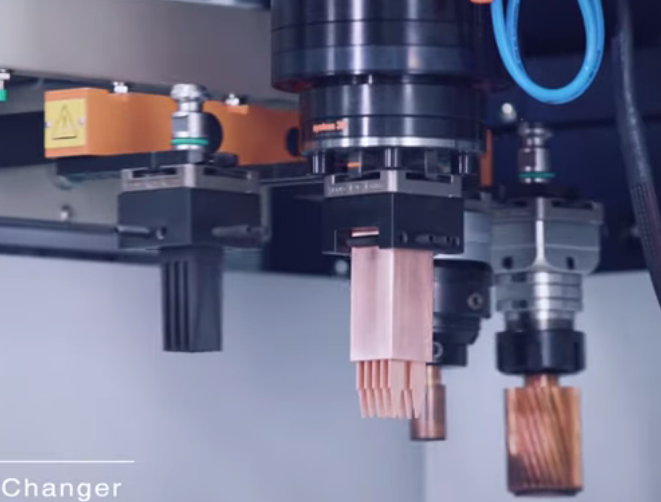

◆ Spindle

It is a key component of the machine tool, which directly affects the process indicators of processing. The structure of the spindle is composed of a feed mechanism, a guide mechanism and an auxiliary mechanism. Generally, the feed mechanism of the spindle can use stepper motor, DC motor or AC servo motor as the feed drive, and drive the spindle to do up and down feed movement through the circular synchronous toothed belt deceleration and rolling screw secondary drive.

The display of the moving position of the spindle is generally indicated by a dial indicator mounted on the spindle, or displayed by a digital display table. The spindle box is fixed on the column as a whole, so that the accuracy of the spindle is well maintained, and it is more convenient to disassemble and assemble.

cnc stepper motor manufacturers

cnc stepper motor manufacturers

◆ Machine tool main lubrication system

It is mainly used to lubricate moving parts such as guide rails and rolling screw pairs of machine tools. These components can be lubricated manually or automatically.

The manual method is to use the manual oil injector to pull the tie rod of the oil injector and press the lubricating oil out of the oil injection cylinder to lubricate the machine tool. The automatic method is to choose an automatic oil injector, and the oil is injected every certain time.

Dongguan Hexing CNC Technology Co., Ltd. is a professional spark machine, milling machine, grinding machine, CNC engraving and milling machine, CNC machining center machine manufacturer, since 1976 in the development of spark machine, has been committed to manufacturing the best all kinds of working machines, and created the brand for Hexing Precision Machine, after decades of efforts, has grown into one of the largest manufacturers of various types of working machines.

CNC Lathe

Hexing Seiki: Since its inception, it has been continuously committed to the improvement of the company’s system, fully invested in the pursuit of the top performance of the machine, and has always insisted on providing users with reasonable prices, excellent quality of all kinds of working machines, each Hexing design and manufacture of the machine is high precision, high performance, high efficiency, long life as the standard, with trustworthy management, strict quality control, skilled manufacturing capabilities, perfect service, successfully shaped the brand of Hexing series Seiki, for the image emblem of high-quality working machines.

Hexing Seiki: professional design, modern production system, Asia except Japan can have self-software development, controller manufacturing to AC servo and drive self-developed manufacturers, adhere to quality tradition, technological innovation and outstanding technical background, ingenuity manufacturing technology, across the machine, electrical and many other fields of a number of patented technology, each process is strictly quality control, meticulous inspection, thoroughly ensure the trust of each Hexing Seiki, so that you can accurately feel the outstanding manufacturing concept of Hexing Seiki.