What do you think of the stepper motor driver breakdown table?

What do you think of the stepper motor driver breakdown table? Stepper motor is a common type of motor, which is widely used in various automation equipment due to its high positioning accuracy and fast response speed. The accuracy and performance of stepper motors are largely limited by the control strategy and number of subdivisions of their drives.

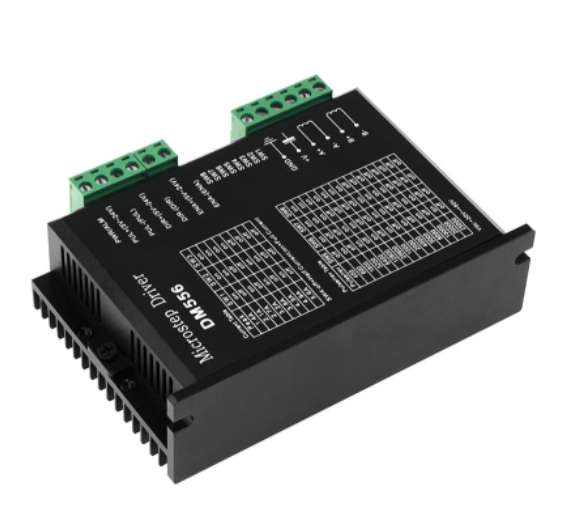

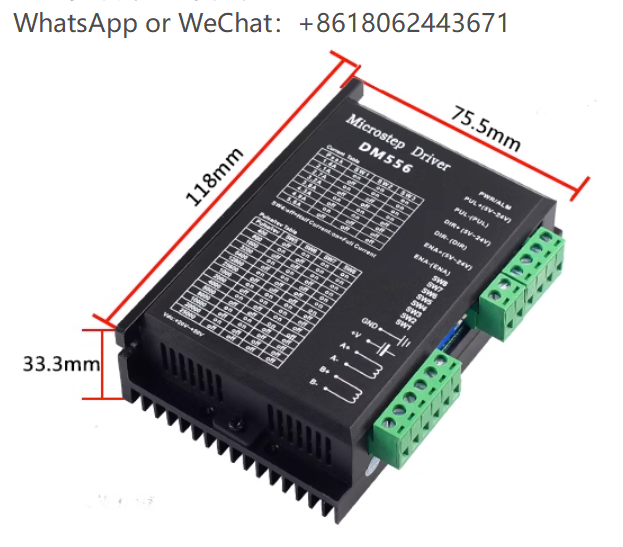

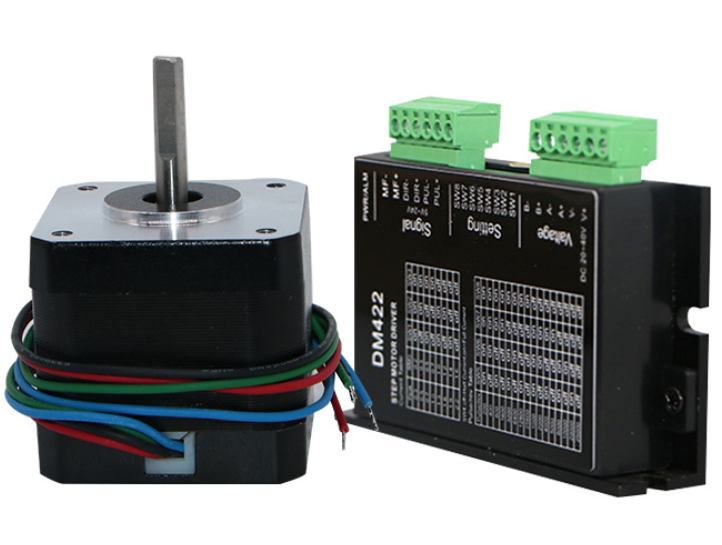

Stepper motor driver 256 subdivision

Stepper motor driver 256 subdivision

1. How to see the stepper motor driver subdivision table

The driver of the stepper motor usually has a multi-stage microstep subdivision function, the higher the number of subdivisions, the smaller the step angle, the higher the accuracy and smoothness of the motor rotation, but it will also have an impact on the stability of the entire control system. Therefore, when selecting a drive, you need to determine the number of segments based on actual needs.

Application of nema 23 stepper motor in cnc 3D printer – Nema 23 stepper motor structure dimensional drawing

When purchasing a drive, a breakdown table is usually provided, which lists the number of segments supported by the drive and the corresponding segmentation, such as 4 segments, 8 segments, 16 segments, etc. Users only need to select the appropriate number of segments according to their needs and purchase the corresponding drives.

2. What does stepper motor drive subdivision mean

The drive subdivision of stepper motor refers to the decomposition of a step angle into several small step angles within a certain period of time, so as to achieve accurate positioning and smooth rotation of the motor.

In general, the higher the subdivision, the smaller the angle of each small step and the more precise the angle at which the motor turns.

Specifically, for example, a 1.8 degree / step stepper motor, if the full step control mode, each control will make it rotate an angle of 1.8 degrees; if the 16 subdivision control method is adopted, this step angle will be decomposed into 16 small step angles, each small step angle is 0.1125 degrees, so the motor rotation is smoother and more accurate.

3. How to select the number of stepper motor drive subdivisions

There are many factors to consider when selecting the number of stepper motor driver segments:

The first is the performance requirements of the stepper motor itself, such as accuracy, speed, etc.

The second is the requirements of the control system, including positioning accuracy, dynamic response speed, stability, etc.

Stepper motor driver subdivision

The actual economic cost also needs to be considered, as drives with high segments are usually more expensive but also provide better performance.

Generally speaking, in most application scenarios, the 8-16 subdivision can meet the general performance requirements. When choosing, it can be considered according to actual needs and economic budget.

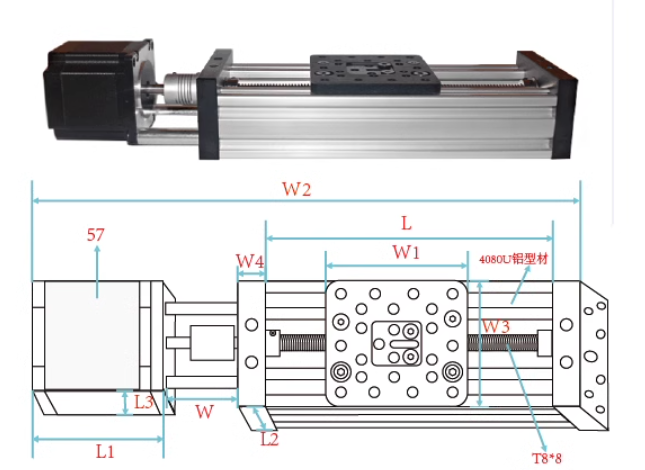

CNC 3D printer laser engraver Z-axis – T8 screw slide module with NEMA 23 stepper motor

Detailed explanation of 3D printer stepper drive subdivision technology

1. What is a stepper motor driver segment?

Basic concepts of segmentation:

The stepper motor is driven by a subdivision drive, and its step angle becomes smaller. If the drive works in the 10 subdivision state, its step angle is only one-tenth of the “fixed step angle”, that is: when the drive works in the unsubdivided full-step state, the control system rotates 1.8 per step pulse; and when the subdivision drive works in the 10 subdivision state, the motor only rotates 0.18 degrees. The subdivision function is completely generated by the drive controlling the phase current of the motor with precision, regardless of the motor. WhatsApp or WeChat:+8618062443671

Figure 1 is a schematic diagram of the working principle of a two-phase stepper motor, which has two windings A and B. When a winding is energized, its stator pole generates a magnetic field that draws the rotor to this pole.

Stepper motor driver subdivision graph

If the winding is under the action of the control pulse, the order of the energization direction is:

These four states change over and over again, and the motor can turn clockwise; Each time the control pulse acts, the direction of power is changed once, so that the motor rotates one step, that is, 90 degrees. 4 pulses, the motor turns one turn.

The principle of subdivision drivers is to change the angle of the synthetic magnetic field by changing the magnitude of the currents in phases A and B, so that a step angle can be subdivided into multiple steps. When the windings of phases A and B are energized at the same time, the rotor will stop in the middle of the magnetic poles of phases A and B, as shown in Figure 1(b), (d). If the order of power-on direction follows:

These 8 states change over and over again, and the motor rotates clockwise; Each step of the motor rotation is 45 degrees, and 8 pulse motors rotate one cycle. Compared to the power-on sequence (1), its step angle is half smaller.

NEMA 34 stepper motor driver 256 subdivision

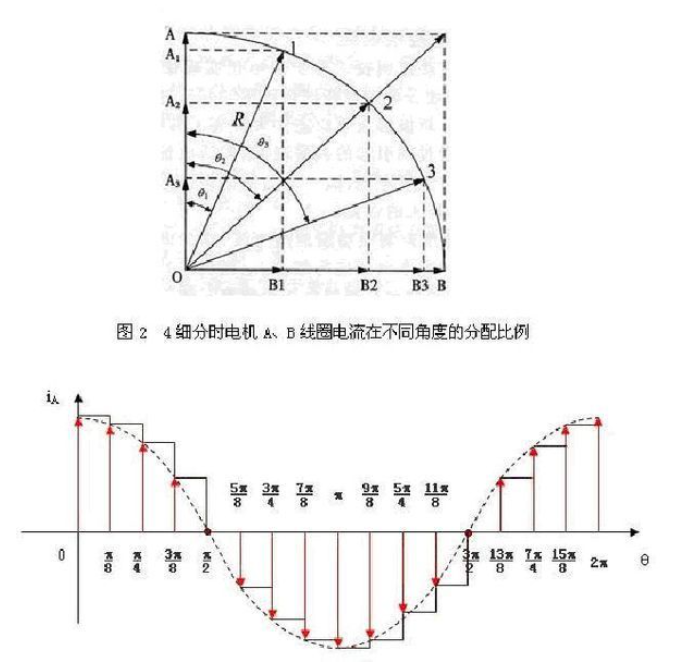

In order to ensure that the torque output by the motor is uniform, the size of the coil current of phases A and B should also be adjusted so that the resultant force generated by phases A and B is the same at each position. Figure 2 shows the ratio of coil currents in phases A and B when the motor is subdivided. The relationship between the current size and the angle of the coil in phase A and B is shown in Figure 3.

Figure 2 4 The distribution ratio of motor A and B coil currents at different angles during subdivision

As can be seen from Figure 3, the phase current of a stepper motor is distributed as a sinusoidal function (as shown by the dashed line); The larger the number of subdivisions, the closer the phase current is to the sinusoidal curve.

CNC 3D printer stepper motor – screw slide module with NEMA 23 stepper motor

2. The relationship between stepper motor subdivision and motor motion stability

The step angle of the stepper motor to be measured is 1.8 degrees, that is, 200 steps per revolution without subdivision. During the test, the speed of the stepper motor is set to 2 r/s; When motor 2 is subdivided, the motor is 400 steps per revolution, and the cycle of each step is 1.25ms; when the motor 8 is subdivided, the motor is 1600 steps per revolution, and the cycle of each step is 0.3125ms; when the motor is subdivided into 64, the motor is 12800 steps per revolution, and the cycle of each step is 0.0391ms. WhatsApp or WeChat:+8618062443671

When the stepper motor 2 is subdivided, the current waveform step is uniform, and the current pulsation value is very large, and its maximum value is 70.7% of the maximum current; when the stepper motor 8 is subdivided, the current waveform step is obvious, but the current pulsation value is small, and its maximum value is 19.5% of the maximum current; when the stepper motor 64 is subdivided, the current waveform is smoother, the current waveform has been difficult to distinguish the number of steps, and the maximum current pulsation value is only 2.45% of the maximum current.

According to the electromagnetic induction theorem, the output torque of a stepper motor is proportional to the current of the motor coil, and:

T = KT × i

where KT is the motor torque constant, which is related to motor structure, material, coil length and other factors.

3D printer stepper motor subdivision driver – WhatsApp or WeChat:+8618062443671

From this, the formula is easy to understand: the higher the number of stepper motor subdivisions, the smoother the motor runs; The smaller the number of stepper motor subdivisions, the greater the vibration when the motor is running. Because when the number of subdivisions is high, the current curve is smooth, so the motor output torque fluctuates small and continuous, and the motor runs smoothly; The motor subdivision number is small, the motor current pulsation is large, and its output torque pulsation is large, resulting in a large vibration of the motor, which vibrates and produces noise and even resonant noise of other components.

3. Conclusion

The stepper motor subdivision drive circuit can not only improve the motion stability of the working platform, but also effectively improve the positioning accuracy of the working platform. The test shows that on the motion platform of the synchronous belt drive, when the stepper motor 4 is subdivided, the motor can be accurately positioned at each step.

3D printer nema 17 stepper motor – What do you think of the stepper motor driver breakdown table?

It is recommended that the number of subdivisions of the stepper motor driver be set as large as possible when the pulse frequency output by the motion controller allows, so as to improve the motion smoothness of the motion platform; However, the positioning accuracy of the motion platform can only be calculated according to the pulse equivalent of the stepper motor 4 subdivision.