The 0.6N.m 1.8 degree 42mm Nema 17 stepper motor with brake is a 42mm size stepper motor with a rated torque of 0.6N.m (Nm) and an angle of 1.8 degrees.

0.6N.m 1.8 degree 42mm Nema 17 stepper motor with brake

The motor has a rated torque of 0.6N.m, meaning it requires a force of 0.6 Nm to turn 1 meter. At the same time, it has an angle of 1.8 degrees, which can provide precise angular displacement control.

When purchasing a 0.6N.m 1.8 degree 42mm Nema 17 stepper motor with brake, it needs to be selected according to the application scenario and load requirements.For example, select the motor length, screw lead, screw stroke, etc. according to your needs.At the same time, it is necessary to consider the speed of the motor, working temperature, ambient humidity and other factors to ensure the stability and reliability of the motor.

Nema 17 Stepper Motor with Brake Specifications – 42 x 42mm Brake Stepper Motor Datasheet

|

Model

|

code

|

NEMA 17 braking torque

|

NEMA 17 brake type

|

NEMA 17 brake stepper motor supply voltage

|

Braking power

|

Response time

|

Temperature rise

|

|

42BK06N24

|

B

|

0.6(N.m)

|

Electromagnetic brakes

|

24VDC±5%

|

3.5W

|

50ms

|

≤55℃

|

Made in :China

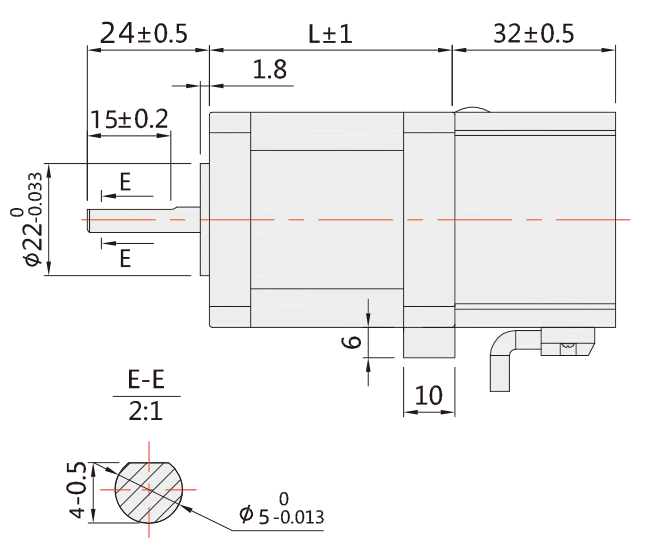

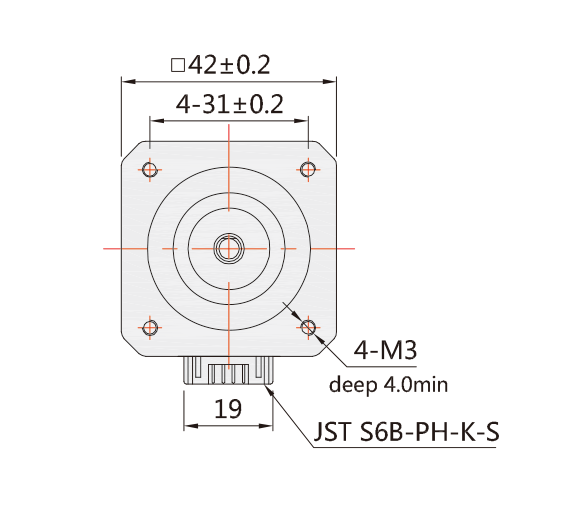

Nema 17 stepper motor with brake dimensions

0.6Nm 42 x 42mm Nema 17 stepper motor with brake dimensions

What are the characteristics of the NEMA 17 brake stepper motor?

The NEMA 17 brake stepper motor is a high-performance, high-precision stepper motor with the following features:

1. High precision: Nema17 stepper motor has high precision and low error, can provide accurate angular displacement and speed, suitable for a variety of high-precision applications.

2. High reliability: Nema17 stepper motor adopts high-quality materials and manufacturing processes, has long life and stable performance, and can work in various harsh environments.

3. Fast response: Nema 17 stepper motor has fast response and high-speed performance, can start and stop quickly, and adapt to various rapidly changing load needs.

4. Multiple specifications: Nema 17 stepper motor has a variety of specifications and options to choose from, including different body length, screw lead, screw stroke, etc., which can be customized according to application needs.

5. Easy maintenance: Nema17 stepper motor maintenance is relatively convenient, only need regular inspection and maintenance, can extend the service life of the motor.

In summary, the Nema17 brake stepper motor is a high-performance, high-precision stepper motor suitable for a variety of high-precision and high-reliability applications such as robotics, automation equipment, medical equipment, and more.

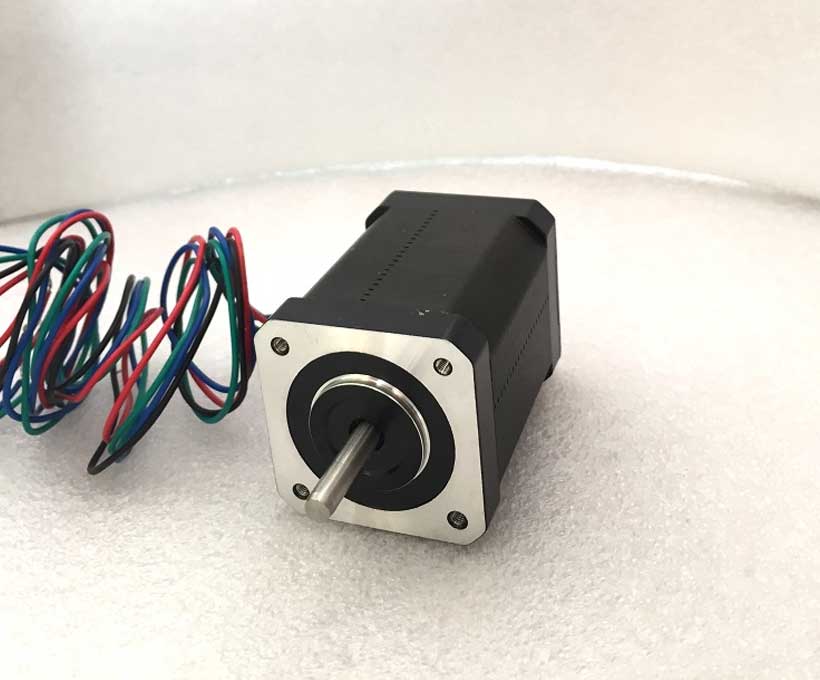

0.6N.m 1.8 degree 42mm Nema 17 stepper motor with brake

How to wire 42mm stepper motor with brake?

The wiring steps for a 42mm stepper motor with brake are as follows:

1. First turn on the power supply of the stepper motor driver, which can be DC 24 volt power supply.

2. Connect the positive pole of the pulse input signal and the direction input signal of the stepper motor driver to the 5V terminal controlled by the instrument.

3. Connect the negative end of the pulse input signal of the stepper motor driver to the Y1 output end of the instrument control.

4. Connect the negative terminal of the input signal of the driving direction of the stepper motor to the output of the instrument control Y2.

5. Set the subdivision of the stepper motor driver, which can generally be placed around 8 (1600). After initial commissioning, set up the actual breakdown required.

42mm stepper motor with brake

6. Set the forward rotation setting of the stepper motor, refer to the setting, and realize the forward rotation in one line. The X1 is a starter switch that rotates forward.

7. Stepper motor reverse setting: X2 is the reverse start switch, Y1 outputs pulse, Y2 outputs direction signal. The two lines do opposite things.

The following points need to be paid attention to when wiring:

1. Ensure the safety of wiring and avoid damage caused by improper wiring.

2. Consider the performance parameters of stepper motors and brakes to ensure that they can be effectively controlled.

nema 17 stepper motor brake circuit

3. Pay attention to the positive and negative polarities of the power supply to avoid failure due to incorrect motor and brake wiring.

4. After completing the wiring, a test should be carried out to ensure that the wiring of the motor and brake is correct.

What are the applications of 42mm stepper motor with brake?

42mm stepper motor with brake is mainly used in the following fields:

1. Automotive industry: 42mm stepper motor with brake can be used in automobile brake system to realize the safety control of the vehicle.

2. Machine tool industry: 42mm 1.8 degree stepper motor with brake can be used for the control system of the machine tool to achieve precise control of the machine tool.

3. Toy industry: 42mm 1.8 degree stepper motor with brake can also be used for the control system of toys to achieve safe control of toys.

4. Ceramic industry: 42mm 0.6Nm stepper motor with brake can be used for the control system of ceramic production line to achieve accurate ceramic production process.

5. Textile industry: 42mm 0.6Nm stepper motor with brake can be used for the control system of textile machinery to achieve accurate textile operation.

6. Lifting industry: 42mm stepper motor with brake can be used for the control system of lifting machinery to achieve accurate lifting operation.

7. Warehousing industry: 42mm stepper motor with brake can be used for the control system of storage machinery to achieve accurate warehousing operation.

NEMA stepper motor with brake manufacturer certificate

8. Printing industry: 42mm 0.6N.m stepper motor with brake can be used for the control system of printing machinery to achieve accurate printing operation.

9. Food industry: 42mm 3.5W stepper motor with brake can be used for the control system of food processing machinery to achieve accurate food processing operations.

10. Elevator industry: 42mm stepper motor with brake can be used for the control system of the elevator control system to realize the safety control of the elevator.

Lathe manufacturers –

We are lathe manufacturers, often buy stepper motor, servo motor products, this NEMA 17 stepper motor is good, high-performance motion control products.