1.2 degree NEMA 34 stepper motor model specification datasheet manual.

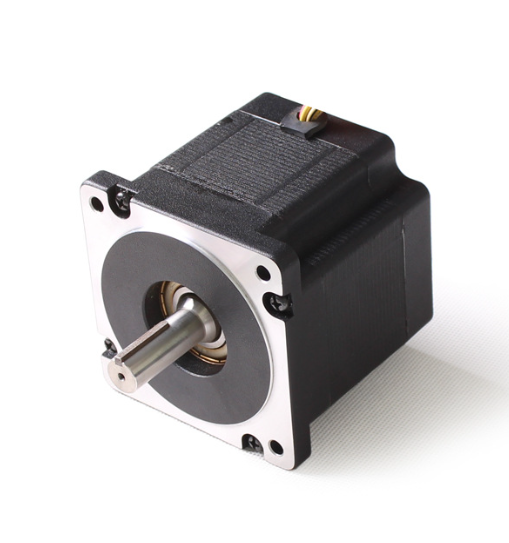

NEMA 34 smooth hybrid stepper motor has smoother, high efficiency, high precision, smooth low-frequency output, high-frequency strong torque is a typical feature of 85 series stepper motors, static torque up to 6.8mNm.

86mm series three-phase hybrid stepper motor, based on the industry’s advanced magnetic circuit design scheme.

In terms of material selection, it is made of high-temperature resistant permanent magnets and high-quality cold-rolled steel sheets, Japanese NMB or NSK bearings are selected, and the surface of the motor is sprayed or sealed with aluminum shell.

motorforum.rfidepc.com NEMA34 standard hybrid stepper motor provided has different body lengths and static torque up to 11.9mNm, low rotor inertia, strong torque, fast acceleration is one of the characteristics of the 85 stepper motor.

Features of 86mm series three-phase hybrid stepper motor :

●Bipolarity 1.2 degrees

●Frame number: 86

●Holding torque: 2.26~6.78N. M

●Large output torque, high speed

●The motor has low heat, low noise and high efficiency

●High-speed stop is smooth and fast, no zero-speed oscillation runs smoothly, and vibration noise is small

●Fast response, suitable for frequent start and stop

1.2 degree NEMA 34 Standard Hybrid stepper motor model specification datasheet manual

NEMA 34 Stepper Motor Model Specification :

| Project | nema 34 stepper motor sheetdata |

| Step angle | 1.2° |

| Step angle accuracy | ±5% (full step, no load) |

| Resistance accuracy | ±10%(@20°) |

| Inductance accuracy | ±20%( 1KHz) |

| Temperature rise | 80℃Max. (Rated current, 2-phase energized) |

| Ambient temperature | -20°~ + 50℃ |

| Insulation resistance | 100MΩ Min.500VDC |

| Withstand pressure | 500VAC /minute |

| Radial clearance | 0.2mmMax.(450g load) |

| Axial clearance | 0.8 mmMax.(450g load) |

NEMA 34 Standard Hybrid Stepper Motor Model Specification Sheet:

dma860h stepper driver datasheet pdf

| Model | Step angle(degree) | Rated current(A) | Phase resistance (Ω) |

Phase inductance (mH) |

Maintain torque (N.M) |

Rotor inertia (g.c㎡) |

weight (kg) |

Long fuselage (mm) |

Shaft diameter (mm) |

Number of leads |

| 863S22 | 1.2 | 325 | 1.75 | 4.25 | 12.3 | 2.26 | 1120 | 67 | 12 | 6 |

| 863S42 | 1.2 | 40 | 5.8 | 0.97 | 3.2 | 4.18 | 2320 | 97 | 12 | 6 |

| 863S42H | 1.2 | 325 | 2 | 5.8 | 21 | |||||

| 863S68 | 1.2 | 40 | 5.2 | 1.8 | 8 | 6.78 | 3300 | 127 | 12 | 6 |

| 863S68H | 1.2 | 325 | 2.25 | 9 | 39 |

1.2 degree stepper motor meaning :

The number of steps/lap == is actually the number of steps used by the stepper motor to walk one lap.

You look at the breakdown of others’ drive steps/laps. In fact, the relative is a few subdivisions.

Like what. 200 steps/lap, which means that it takes 200 steps to walk a circle. 1 step is 1.8 degrees.

If it is a two-phase stepper motor. This 200 steps/lap is no subdivision. It’s a whole step to go.

Because the 1.8 degree angle is the basic step angle of the two-phase stepper motor.

86mm 1.2° three-phase hybrid stepper motor – 1.2 degree NEMA 34 stepper motor model specification datasheet manual

If you turn it up to .2,000 steps/lap, it takes 2,000 steps to walk a lap. Walking 1 step is 0.18 degrees.

Because the basic step angle of the two-phase stepper motor is 1.8 degrees, and now walking 1 step is 0.18 degrees.

That is, 1.8/0.18=10, and this 10 is a 10 subdivision.

When you tune to 2000 steps/lap it is quite subdivided with tuning to 10.

Explanation of the original and function of stepper motor driver subdivision

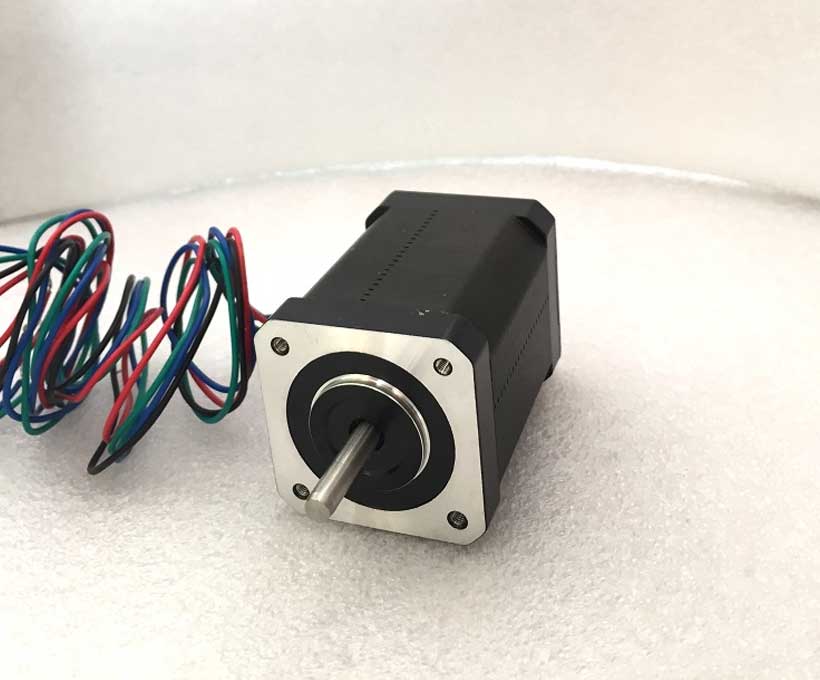

Stepper motors are widely used in electronic equipment, textile equipment, medical equipment, advertising equipment and other fields.

The stepper motor and the stepper motor driver constitute the stepper motor drive system.

The performance of the stepper motor drive system depends not only on the performance of the stepper motor itself, but also on the advantages and disadvantages of the stepper motor driver.

The study of stepper motor drives was carried out almost simultaneously with the study of stepper motors.

A stepper motor driver is an actuator that converts electrical impulses into angular displacement. When the stepper driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle (called “step angle”) in the set direction, and its rotation is run step by step at a fixed angle.

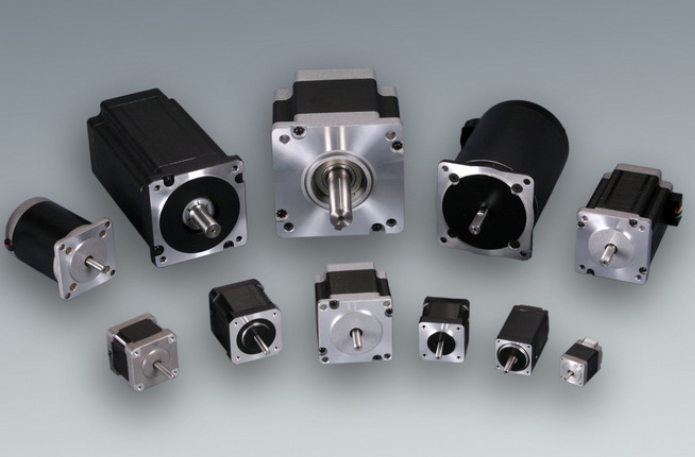

Nema 34 stepper motor manufacturers in China

Nema 34 stepper motor manufacturers in China

The amount of angular displacement can be controlled by controlling the number of pulses, so as to achieve the purpose of accurate positioning; At the same time, the speed and acceleration of motor rotation can be controlled by controlling the pulse frequency, so as to achieve the purpose of speed regulation and positioning.

Widely used in engraving machines, crystal grinding machines, medium-sized CNC machine tools, EEG embroidery machines, packaging machinery, fountains, dispensing machines, cutting feeding systems and other large and medium-sized CNC equipment with high resolution.

The number of phases of the stepper motor refers to the number of coil groups inside the motor, and the commonly used two-phase, three-phase, four-phase and five-phase stepper motors are commonly used.

The number of motor phases is different, and its step angle is also different, generally the step angle of two-phase motor is 1.8 degrees, the three-phase is 1.2 degrees, and the five-phase is 0.72 degrees. In the absence of a subdivision drive, the user mainly relies on the selection of stepper motors with different phase numbers to meet the requirements of the step angle.

dc stepper motor

If a subdivision drive is used, the phase number becomes meaningless, and the user can change the step angle simply by changing the subdivision number on the drive.

The subdivision of stepper motor drives will make a qualitative leap in the operating performance of the motor, but all this is generated by the drive itself, and has nothing to do with the motor and control system.

When in use, the only point that users need to pay attention to is the change of the step angle of the stepper motor, which will have an impact on the frequency of the step signal sent by the control system, because the step angle of the stepper motor will become smaller after subdivision, and the frequency of the step signal is required to increase accordingly.

1.2° three-phase hybrid stepper motor

Take a 1.8-degree stepper motor as an example: the step angle of the driver is 0.9 degrees in the half-step state, and the step angle is 0.18 degrees in the ten-subdivision state, so that the frequency of the step signal sent by the control system is 5 times that of the half-step operation in the case of the same motor speed.

Generally, the accuracy of the stepper motor is 3~5% of the stepping angle. The deviation of a single step of the stepper motor does not affect the accuracy of the next step, so the accuracy of the stepper motor does not accumulate.

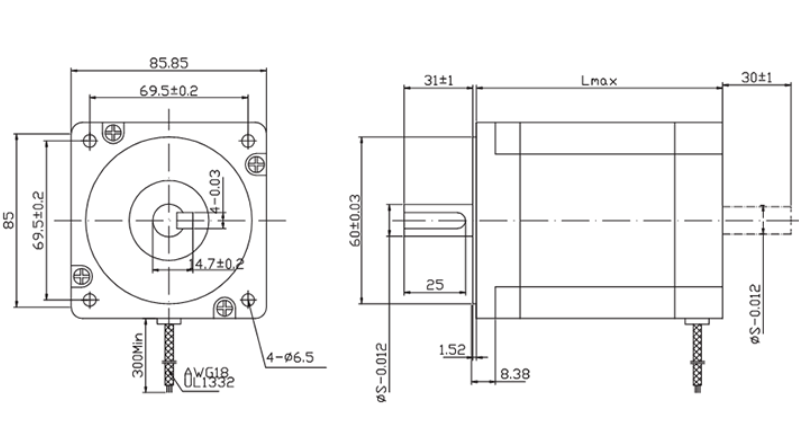

Nema 34 stepper motor dimensions

Nema34 reduction stepper motor – gear reduction motor – reduction ratio can be customized

Video demonstration of the working process of NEMA34 reduction stepper motor

Cybercom Ltd. –

Hello everyone, I am the head of the Russian 3D printing company Cybercom Ltd. in China, I bought a servo motor on this website, very good, hereby to express my opinion, you can choose according to your own industry, I was ready to choose a stepper motor, but I think, or servo motor is better; I hope my evaluation can help friends.

Ankors –

My name is Ankors, from Spain, I am very grateful to this seller, the product production place is in Shenzhen, China, I bought this stepper motor is mainly used in CNC machine tools, the whole installation test of the product has technical guidance, thank the seller. Hope we can cooperate for a long time.

KenDevCNC –

Purchased many times The quality is very good, the transmission reducer is just equipped with the motor, the service is thoughtful, the purchase is shipped quickly, there is no problem after receiving the goods and trying, good quality, low noise, simple and easy to install, very satisfied [very strong]

Indian packaging machine manufacturer –

The servo motor manufacturer is Chinese, I bought this set of manufacturers installed, it is much easier to install! Low noise, good quality and affordable price, fast delivery logistics, standard model specifications and sizes, and good service! Next time repurchase [strong] [strong]

Indian packaging machine manufacturer –

The servo motor manufacturer is from China, and the set I bought is already installed by the manufacturer, which is a stepper motor + drive.

Cutting manufacturers –

This stepper motor has been used for a while, the performance is stable, the sound is not loud when running, the start is fast, the power is strong, the number of revolutions is also very high, and the long-term work is not hot. This set of factory technology tried no problem, much better than the last time I bought in another house, not only good service, fast delivery, quality first