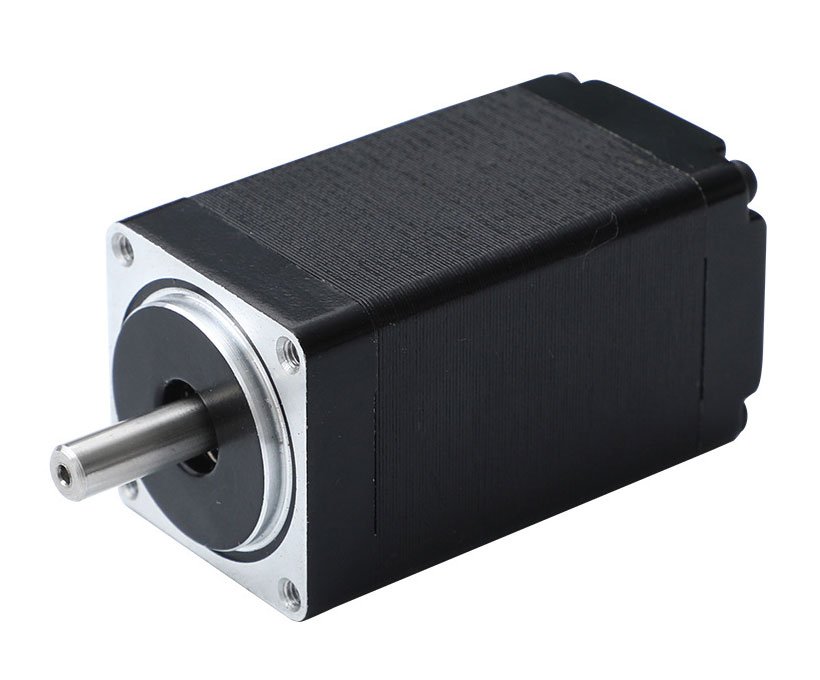

12.5Nm servo motor – 6A 1.8 degree 86mm hybrid closed-loop stepper motor. NEMA 34 closed-loop stepper motor 12nm, 1.8 degree step angle, high precision, fast response.

12.5Nm servo motor – 6A 1.8 degree 86mm hybrid closed-loop stepper motor

NEMA 34 closed-loop stepper motors are typically used in automation equipment that requires high accuracy and speed.

It is a high-performance stepper motor.

NEMA 34 hybrid servo motor is a common servo motor commonly used in various automation equipment such as robots, CNC machine tools, automated production lines, etc.

NEMA 34 closed-loop stepper motor manufacturer – 12.5N. M servo motor – 6A 1.8 degree 86mm hybrid closed-loop stepper motor

NEMA 34 hybrid servo motors have the following features:

High efficiency: Hybrid design with high efficiency and power density to meet high load and high speed requirements.

High precision: Closed-loop control with high positioning accuracy and repeatability, suitable for applications requiring high precision.

High reliability: The use of high-strength materials and sealing design, with high impact and corrosion resistance, suitable for harsh working environments.

Long life: Low wear design for long service life and low maintenance costs for applications requiring long operation.

nema 34 stepper motor manufacturers in China

Easy to control: Support a variety of control methods, such as position control, speed control, torque control, etc., easy to integrate and control with various automation equipment.

In summary, the NEMA 34 hybrid servo motor is a high-performance, reliable, easy-to-control servo motor suitable for a variety of automation applications.

86mm hybrid servo motor naming

|

MY

|

86

|

CM

|

L

|

05

|

D

|

8

|

–

|

XX

|

|

brand

|

flange

|

type

|

Encoder resolution

|

Torque

|

Out of the shaft

|

Shaft diameter

|

Non-standard parameters

|

|

|

RFIDEPC.COM

|

86:86mm:nema 34 |

CM: Hybrid servo motor CD: Hybrid servo drives |

L: Encoder resolution 1000 lines

H: Encoder resolution 2500 lines

|

05: The holding torque is 0.5N.m

08: The holding torque is 0.8N.m

|

A: Round shaft output

D: Unilateral washing U: Wash the keyway |

4:4mm

5:5mm 8:8mm |

Custom codename

|

12.5N. M Servo Motor Specifications – 6A 1.8 Degree 86mm Hybrid Closed Loop Stepper Motor Datasheet

| Model | Encoder resolution | Motor length (mm) | Hold torque (N.M) | Rated current (A) | Rotor moment of inertia (g.cm²) | kg | Encoder output circuit | Encoder origin signal | Drivers are fitted as standard |

|

MY86CML45-U14

|

1000CPR

|

(80+23)

103

|

4.5

|

6.0

|

1950

|

2.5

|

Differential input

|

NO | Hybrid servos

Pulse type MY86CDL MY86CDH |

|

MY86CMH45-U14

|

2500CPR

|

Yes | |||||||

| MY86CML85-U14 |

1000CPR

|

(118+23)

141

|

8.5

|

6.0

|

2800

|

4.0

|

Differential input | NO | |

| MY86CMH85-U14 |

2500CPR

|

Yes | |||||||

| MY86CML125-U14 | 1000CPR | (152+23)

175 |

12.5 | 6.0 | 4000 | 5.2 | Differential input | NO | |

| MY86CMH125-U14 | 2500CPR | Yes |

★ Drive options: pulse triggering, IO programming, RS485 communication, CANopen communication, EtherCAT communication.

★ 86mm hybrid closed loop stepper motor 12nm

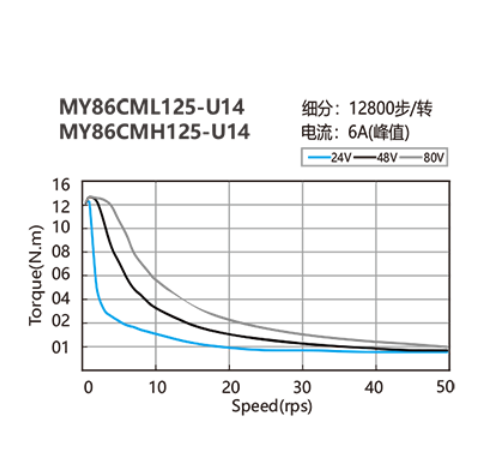

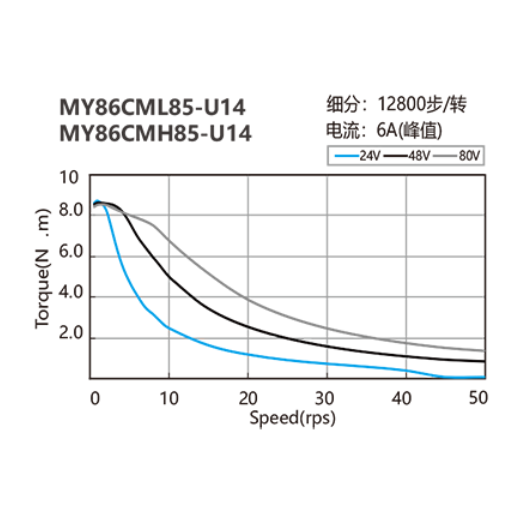

12.5N. M Closed Loop Stepper Motor – 1.8 degree NEMA 34 hybrid servo motor speed torque curve

Stepper motor with encoder – 1.8 degree closed-loop stepper motor MY86CML125-U14 speed torque curve

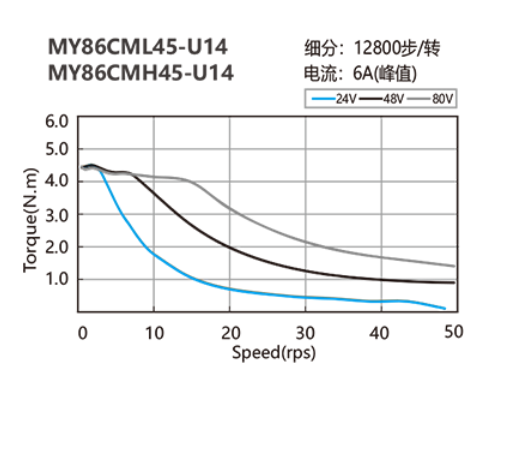

12.5N. M closed-loop stepper motor MY86CML45-U14 speed torque curve

12.5Nm 1.8 degree closed-loop stepper motor MY86CML85-U14 speed torque curve

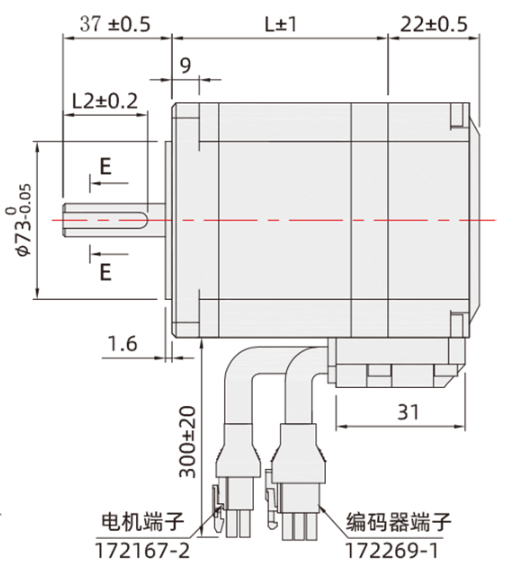

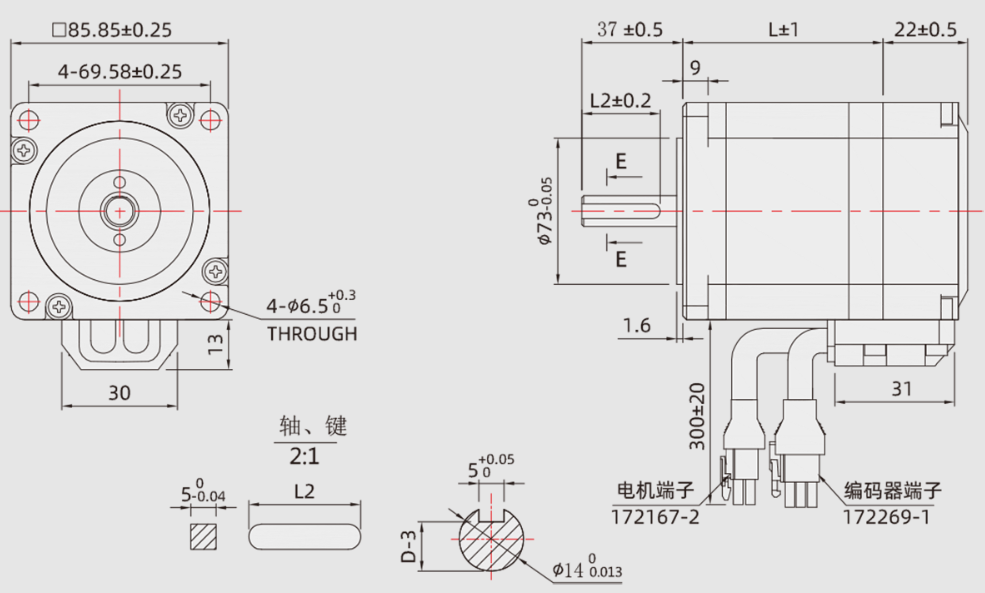

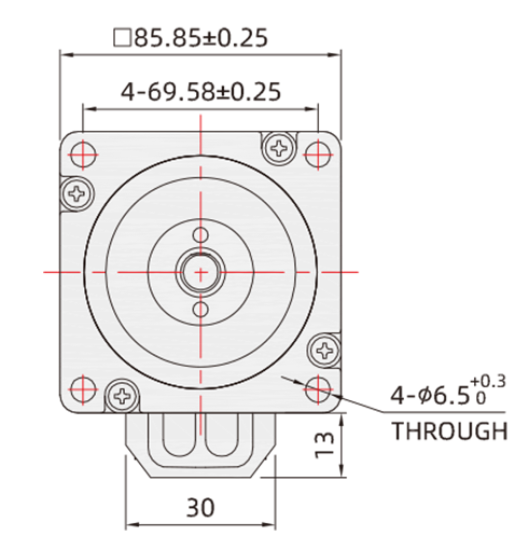

Nema 34 stepper motor mounting dimensions

nema 34 stepper motor dimensions

nema 34 stepper motor mounting dimensions

NEMA 34 stepper motor with encoder size – Nema 34 closed loop stepper motor 12nm

NEMA 34 Closed-Loop Stepper Motor Instructions:

1. About the installation direction of NEMA 34 closed-loop stepper motor: The installation direction of the motor can be installed freely from either direction, upward and downward. Pay attention to the suspension load and axial load of the shaft regardless of the direction.

nema 34 closed loop stepper motor kit

2. For 86mm hybrid servo motor, please be careful not to let the cable contact with the installation surface, causing unnecessary pressure.

3. NEMA 34 closed-loop stepper motor installation method: please try to consider the problem of heat dissipation and vibration prevention, firmly fix it on the strong metal surface, be sure to use the front end of the motor installation stop positioning, and pay attention to the tolerance to strictly ensure the concentricity of the motor output shaft and the load.

NEMA 34 Closed-Loop Stepper Motor

4. The peak current setting of the driver must be less than the rated current of the motor. Do not carry the motor cable directly.

NEMA 34 closed-loop stepper motors are widely used in the following areas:

1. CNC machine tools: NEMA 34 closed-loop stepper motor can be used for high-precision CNC machine tools to achieve high-precision cutting, drilling and other processing operations.

2. Robot: NEMA 34 closed-loop stepper motor can be used for robots to achieve high-precision positioning, grasping and other operations.

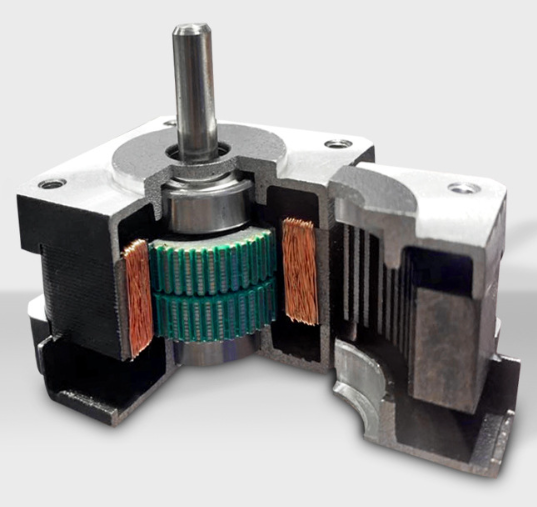

NEMA 34 closed-loop stepper motor internals

3. Precision instruments: NEMA 34 closed-loop stepper motor can be used in various precision instruments, such as optical instruments, measuring instruments, etc., to achieve high-precision measurement and calibration.

4. Automation equipment: NEMA 34 closed-loop stepper motor can be used in various automation equipment, such as packaging machines, printing machines, etc., to achieve high-efficiency production processes.

5. Assembly line: NEMA 34 closed-loop stepper motor can be used in various assembly lines, such as assembly lines, inspection lines, etc., to achieve high-efficiency flow operations.

Nema 34 stepper motor with encoder – Nema 34 closed loop stepper motor 12nm

6. Other fields: NEMA 34 closed-loop stepper motor can also be used in medical equipment, scientific research equipment, aerospace and other fields to achieve high-precision and high-efficiency operation.

12.5N. M Servo Motor – 6A 1.8 degree 86mm hybrid closed-loop stepper motor in practical application

The applications of NEMA 34 closed-loop stepper motors in IC sorters mainly include the following aspects:

1. Chip picking: The IC sorter uses NEMA 34 closed-loop stepper motor to realize chip pickup. The motor drives devices such as robotic arms or suction cups, and by controlling the movement of the motor, high-precision and high-efficiency chip picking operations can be realized.

closed loop stepper motor nema 34

2. Chip sorting: The IC sorter uses NEMA 34 closed-loop stepper motor to achieve chip sorting. According to the type of chip, specifications and other parameters, by controlling the movement and speed of the motor, different needs of sorting operations can be realized, including classification according to the pin spacing and number of pins of the chip.

3. Chip placement: The IC sorter uses NEMA 34 closed-loop stepper motor to achieve chip placement. The motor drives devices such as robotic arms or suction cups, and by controlling the movement of the motor, the chip can be placed in a designated position, such as a circuit board, test equipment, etc.

86mm hybrid closed loop stepper motor 12nm

4. Chip detection: The IC sorter uses NEMA 34 closed-loop stepper motor to realize chip detection. Motor-driven detection devices, such as microscopes, image recognition systems, etc., can achieve high-precision detection and recognition of various features of the chip by controlling the movement and speed of the motor.

5. Automated assembly line: The IC sorter uses NEMA 34 closed-loop stepper motor to realize automatic assembly line operation. By controlling the movement and speed of the motor, precise linkage between different equipment can be realized, such as chip picking, sorting, placement and other operations, improving production efficiency and quality.

Nema 34 stepper motor datasheet – Nema 34 stepper motor wiring diagram

In summary, NEMA 34 closed-loop stepper motors play an important role in IC sorters, enabling a variety of automated operations to improve productivity and quality. As technology continues to evolve, the application areas of NEMA 34 closed-loop stepper motors will continue to expand.

12nm closed-loop stepper motor –

The 12nm closed-loop stepper is of good quality, thanks to the seller

injection molding machine manufacturers –

We are injection molding machine manufacturers, I choose to use closed-loop stepper motor products, this servo motor manufacturer’s closed-loop stepper motor is very good, their company in Shenzhen, China, has a closed-loop stepper motor manufacturing factory. The price is also affordable, mainly because this closed-loop stepper motor has good performance, fast response and long working time.