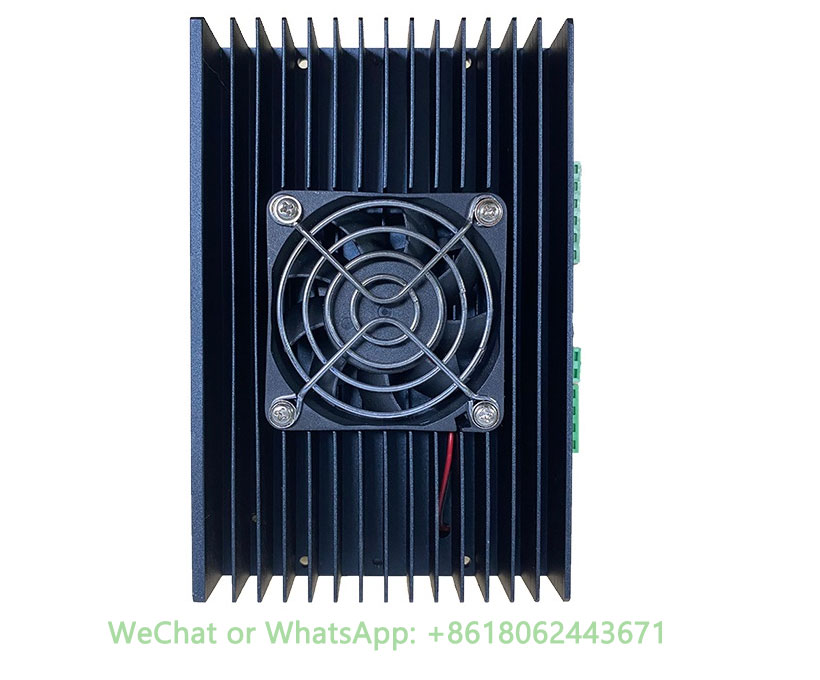

High voltage 2 phase stepper motor driver DM2272A specifications

High voltage two-phase stepper motor driver DM2272A features:

● Intelligent current control, improve the dynamic Q value, so that the motor heat generation is greatly reduced.

● Anti-resonance technology, easy to break through the medium speed resonance zone, good medium and high speed characteristics.

● Adaptive smoothing function. Good low-speed smoothness and low noise.

● Improved PWM control algorithm makes the motor and driver smaller.

● Full-flow to half-flow without obvious noise and vibration.

● Can drive 57.86 two-phase stepper motor driver.

● Impulse response frequency up to 200KHz.

● With overvoltage, undervoltage, short circuit and other protection functions.

● AC voltage input AC85-265V.

● Opto-isolated differential signal input.

● Easy current setting.

High voltage two-phase stepper motor driver datasheet specifications

Control signal interface:

| name | illustrate |

| PUL+ | Pulse control signal: pulse rising edge is effective; PUL-4~5V at high level, 0~0.5V at low level. For reliable response to impulse signals, the pulse width should be greater than 1.2μs. If +12V or +24V is used, a string resistor is required. |

| PUL- | |

| DIR+ | When the input mode is pulse + direction, as a direction signal: high/low level signal, in order to ensure reliable commutation of the motor, the direction signal should be established at least 5μs before the pulse signal. The initial running direction of the motor is related to the wiring of the motor, and the exchange of any phase winding (such as A+, A- exchange) can change the direction of the initial operation of the motor, DIR-4~5V at high level, 0~0.5V at low level. If +12V or +24V is used, a string resistor is required. |

| DIR- | |

| ENA+ | Enable signal: This input signal is used to enable or disable. When ENA+ is connected to +5V, ENA- is connected to low (or internal optocoupler on), the driver will cut off the current of each phase of the motor so that the motor is in a free state, and the step pulse is not responded. When this function is not needed, the enable signal can be left in the air. |

| EAA- | |

| FAU+ | Positive alarm output |

| FAU- | The alarm output is negative |

Add me WeChat or WhatsApp: +8618062443671

High voltage two-phase stepper motor driver DM2272A current setting:

Note: The drive parameters are based on the following table, and the pictures are slightly different.

| Output current | Reference current | SW1 | SW2 | SW3 |

| 2.00A | 1.41A | on | on | on |

| 3.00A | 2.12A | off | on | on |

| 3.80A | 2.68A | on | off | on |

| 4.50A | 3.20A | off | off | on |

| 5.20A | 3.67A | on | on | off |

| 5.80A | 4.10A | off | on | off |

| 6.50A | 4.60A | on | off | off |

| 7.20A | 5.10A | off | off | off |

High voltage two-phase stepper motor driver subdivision setting:

| Steps/turn | SW5 | SW6 | SW7 | SW8 |

| 200 | on | on | on | on |

| 400 | off | on | on | on |

| 800 | on | off | on | on |

| 1600 | off | off | on | on |

| 3200 | on | on | off | on |

| 6400 | off | on | off | on |

| 12800 | on | off | off | on |

| 25600 | off | off | off | on |

| 1000 | on | on | on | off |

| 2000 | off | on | on | off |

| 4000 | on | off | on | off |

| 5000 | off | off | on | off |

| 8000 | on | on | off | off |

| 10000 | off | on | off | off |

| 20000 | off | off | off | off |

| 25000 | off | off | off | off |

The product is widely used in woodworking engraving machines, CNC machine tools, computer embroidery machines, packaging equipment, ceramic equipment and laser cutting equipment.

Computer embroidery machine is the most advanced embroidery machine in contemporary times, which can make the traditional manual embroidery achieve high speed and high efficiency, and can also achieve the requirements of “multi-level, multi-functional, unified and perfect” that manual embroidery cannot achieve.

It is a kind of mechanical and electrical products reflecting a variety of high-tech China’s domestic computer embroidery machine is mainly a high-end model, compared with the above international brands, there is still a certain gap, mainly in terms of process technology and materials, domestic machines can not be compared with these high-end brands, manifested as service life, wire breaking rate, embroidery accuracy and other differences.

However, due to the relatively low price of domestic computer embroidery machines, the development speed has been rapid in recent years, occupying most of the market share, motors and drives can use Chinese manufacturers (motorforum.rfidepc.com) this combination.

High voltage Two-phase stepper motor driver datasheet specifications

Contact us: WhatsApp: +8618062443671

Automatic packaging machines are generally divided into two types: semi-automatic packaging machines and fully automatic charter machines. Automatic packaging machine is mainly used for automatic packaging of materials in food, medicine, chemical and other industries and plant seeds. Materials can be granules, tablets, liquids, powders, pastes, etc.

The automatic packaging machine has the functions of automatic measurement, filling, bag making, sealing, cutting, conveying, printing production batch numbers, adding easy incision, no material warning, stirring and so on.

The automatic packaging machine has advanced design, reasonable structure and reliable performance.

The automatic packaging machine adopts double synchronous belt pulling film, which is controlled by the cylinder tensioning, automatic correction, automatic alarm protection function, and minimizes loss.

The measuring device is matched, integrating bag making, filling, filling, printing and counting. The metering device can be modified according to the material.

It can be used with drives and motors from Chinese manufacturers (motorforum.rfidepc.com).

Matching our stepper motors: 86mm two-phase hybrid stepper motor, 110mm two-phase hybrid stepper motor.

chris –

This servo motor manufacturer product is very easy to use, this high voltage stepper motor drive is very affordable.