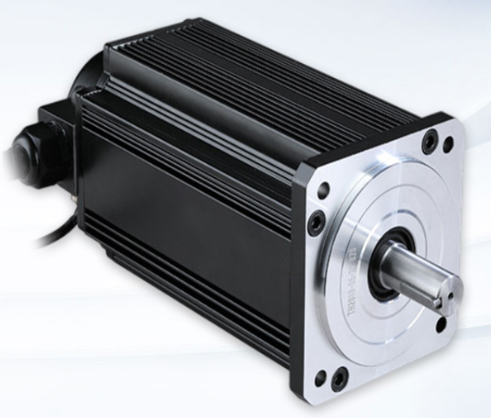

NEMA 17 closed-loop stepper motor (built-in encoder) – 42mm hybrid servo motor.

NEMA 17 closed-loop stepper motor (with encoder) product is developed by Shenzhen Intelligent Servo Motion Control Co., Ltd., we are factory direct sales.

NEMA 17 Closed-Loop Stepper Motor Nomenclature

|

MY

|

42

|

CM

|

L

|

05

|

D

|

8

|

–

|

XX

|

|

brand

|

flange

|

type

|

Encoder resolution

|

Torque

|

Out of the shaft

|

Shaft diameter

|

Non-standard parameters

|

|

|

RFIDEPC.COM

|

20:20mm

28:28mm 42:42mm |

CM: Hybrid servo motor |

L: Encoder resolution 1000 lines

H: Encoder resolution 2500 lines |

05: The holding torque is 0.5N.m

08: The holding torque is 0.8N.m |

A: Round shaft output

D: Unilateral washing U: Wash the keyway |

4:4mm

5:5mm 8:8mm |

Custom codename

|

NEMA 17 closed-loop stepper motor model specifications – 42mm hybrid servo motor data specification sheet

|

Model

|

Encoder resolution | Motor length (mm) | Hold torque (N.M) | Rated current (A) | Rotor moment of inertia (g.cm²) | Motor weight (kg) |

Encoder output circuit

|

Encoder origin signal | Drivers are fitted as standard |

|

MY42CML05-D5

|

1000CPR

|

(49+20)69

|

0.48

|

2.0

|

85

|

0.42

|

Differential input

|

NO | Hybrid servos

Pulse type MY42CDL

MY42CDH |

|

MY42CMH05-D5

|

2500CPR

|

Yes | |||||||

| MY42CML08-D5 |

1000CPR

|

(65+20)85

|

0.72

|

2.0

|

125

|

0.53

|

Differential input

|

NO | |

| MY42CMH08-D5 |

2500CPR

|

Yes |

★ Drive options: pulse triggering, IO programming, RS485 communication, CANopen communication, EtherCAT communication.

★ For related 2D, 3D drawings, please contact Shenzhen Intelligent Servo Motion Control Co., Ltd. (servosteppersupplier@gmail.com) sales staff.

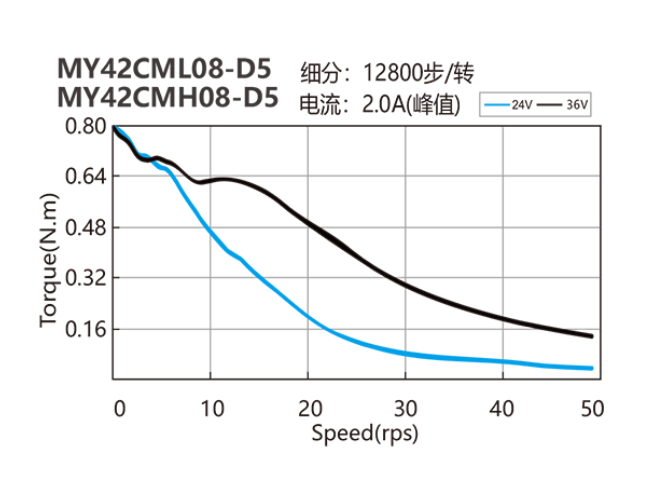

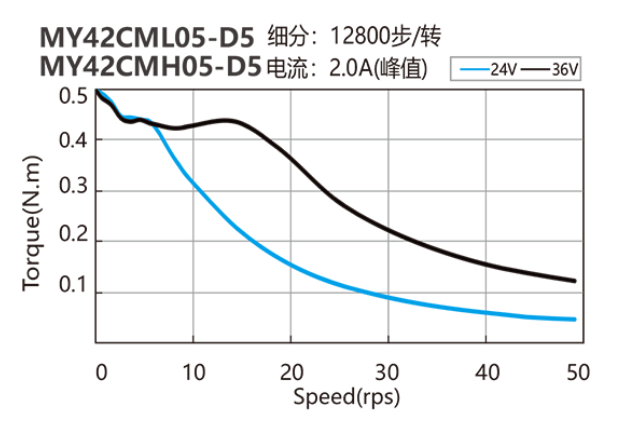

Dynamic torque curve

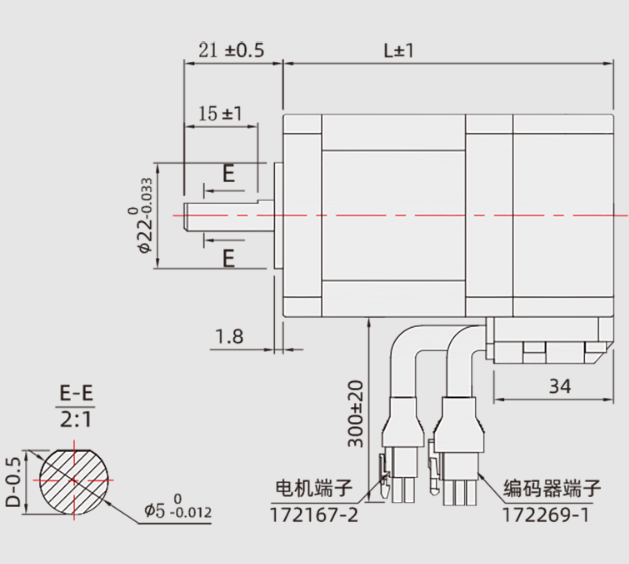

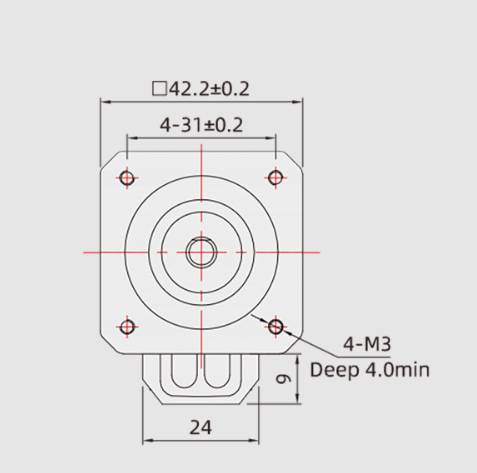

NEMA 17 Closed Loop Motor Dimensional Drawing – 42mm 1.8 degree hybrid servo motor flange size appearance drawing

NEMA 17 Closed Loop Motor Dimensional Drawing – 42mm 1.8 degree hybrid servo motor flange size appearance drawing

42mm 1.8 degree hybrid servo motor flange size appearance drawing

NEMA 17 closed-loop stepper motor (built-in encoder) instructions for use

1. About the installation direction of the motor: The installation direction of the motor can be installed freely in either direction, horizontally, upward, and downward. Pay attention to the suspension load and axial load of the shaft regardless of the direction.

Chinese manufacturer NEMA 17 stepper motor with encoder

2. In addition, please be careful not to let the cable contact with the installation surface, causing unnecessary pressure.

3. NEMA 17 closed-loop stepper motor (built-in encoder) installation method: please try to consider the problem of heat dissipation and vibration prevention, firmly fix it on the strong metal surface, be sure to use the front end of the motor to install the stop positioning, and pay attention to the tolerance to strictly ensure the concentricity of the motor output shaft and the load.

NEMA 17 closed-loop stepper motor (built-in encoder) – 42mm hybrid servo motor

4. The peak current setting of the driver must be less than the rated current of the motor.

5. Do not carry the motor cable directly.

NEMA 17 stepper motor with encoder internal

NEMA 17 closed-loop stepper motor (built-in encoder) applications

Woodworking engraving machine, laser engraving machine, marking machine, labeling machine, solid crystal machine, wire bonding machine, UV printer, 3D printer, inkjet printer, plotter, embroidery machine, dispensing machine, glue filling machine, soldering machine, BGA rework table, laminating machine, placement machine, heat pressing machine, backlight film machine, coating machine, reciprocating machine, terminal machine, stripping machine, winding machine, solder paste printing machine, PCB drilling machine, V-CUT machine target machine, FPC reinforcement machine, coating machine, laminating machine, IC sorting machine, IC burning machine, taping machine, Medical equipment, non-standard equipment, XYZ measuring instrument, connector assembly machine, SMT peripheral equipment, etc.

What is the CE certification of hybrid servo motors? Hybrid servo motor CE certification can’t be?

Servo motor export to the EU for CE certification related requirements|How to handle?

Servo motor refers to the engine that controls the operation of mechanical elements in the servo system, and is an indirect speed change device that supplements the motor.

NEMA 17 1.8 degree stepper motor with encoder

The servo motor can control the speed, the position accuracy is very accurate, and the voltage signal can be converted into torque and speed to drive the control object.

There are many application fields, as long as there is a power source, and the accuracy requirements may generally involve servo motors, such as machine tools, printing equipment, packaging equipment, textile equipment, laser processing equipment, robots, automated production lines and other equipment with relatively high requirements for process accuracy, processing efficiency and work reliability. Let’s introduce the relevant requirements for CE certification of servo motors exported to the EU.

NEMA 17 Closed-Loop Stepper Motor (Internal Encoder) Manufacturer Warehouse Video

Technical documents to be prepared for NEMA 17 servo motor CE certification:

1. Product instruction manual

2. Product technical conditions (or enterprise standards), establish technical data

3. Product electrical schematic diagram, circuit diagram, block diagram

4. List of key components or raw materials (please choose products with European certification marks)

5. A copy of the whole machine or component recognition certificate

6. Other required information

nema 17 servo motor manufacturers in China – MY42CM NEMA 17 hybrid servo motor

Process of CE certification of NEMA 17 servo motors:

Step 1: 1. Fill in the application form 2. Apply for the company information form 3. Provide product information

Step 2: Determine the test standard, test time and corresponding cost according to the information provided (the cost mainly depends on the instruction testing and certification corresponding to the product)

Step 3: After the applicant confirms the quotation, sign the case registration application form and service agreement and pay the fee.

NEMA 17 stepper motor with encoder

Step 4: The laboratory conducts a full set of tests on the applied products and the difference tests of relevant models according to the relevant EU testing standards

Step 5: The test is passed and the report is completed

Step 6: The project is completed and a CE certificate is issued

For more questions about servo motor CE certification or other certification, please call to consult CMK certification, we will provide you with high-quality certification explanations and intimate certification services!

Kenr –

The closed-loop stepper motor price is very affordable, the product quality is also very good, I am honored to know this seller.