1.8 degree 2 phase 0.98Nm 1.89Nm 2.5Nm 3Nm NEMA 23 stepper motor specifications. NEMA 23 stepper motor torque: 0.98Nm, 1.89Nm, 3.00Nm, 2.50Nm.

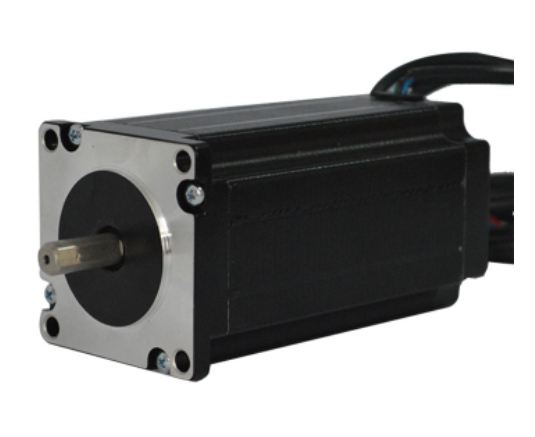

0.98Nm, 2.5Nm, 1.89Nm, 3Nm NEMA23 stepper motor has the characteristics of large output torque, low temperature rise, low noise and low vibration, high reliability and stability.

The motor runs smoothly without obvious oscillation zone, which can meet the use of different working conditions in the automation industry.

NEMA 23 two-phase 1.8 degree stepper motor specifications

| items | Nema 23 stepper motor datasheet |

| Step angle | 1.8° |

| Step angle accuracy | ±5%(Full step, no load) |

| Resistance accuracy | ±10%(@20°) |

| Inductance accuracy | ±20%( 1KHz) |

| Temperature rise | 80℃Max.(Rated current, 2 phases energized) |

| Ambient temperature | -20°~ + 50℃ |

| Insulation resistance | 100MΩMin.500VDC |

| Withstand pressure | 500VAC/Min |

| Radial clearance | 0.02mmMax.(450g load) |

| Axial clearance | 0.08 mmMax.(450g load) |

| Radial maximum load | 75N(20mm from the flange surface) |

| Axial maximum load | 15N |

1.8 degree 2-phase NEMA23 stepper motor model specification parameters

| Model | Wiring method | Step angle

(degrees) |

Rated current

(A) |

Phase resistance (Ω) | Phase inductance (mH) |

Maintain torque (N.M) |

Rotor inertia

(g.c㎡) |

Long fuselage (mm) |

Shaft diameter

(mm) |

Leads |

| 57HS09 | concatenation | 1.8 | 1.98 | 1.60 | 4.80 | 0.98 | 300 | 56 | 6.35 | 4or8 |

| parallel connection | 3.96 | 0.40 | 1.20 | |||||||

| 57HS18 | concatenation | 1.8 | 2.82 | 1.40 | 6.40 | 1.89 | 480 | 76 | 6.35ro8 | 4or8 |

| parallel connection | 5.65 | 0.35 | 1.60 | |||||||

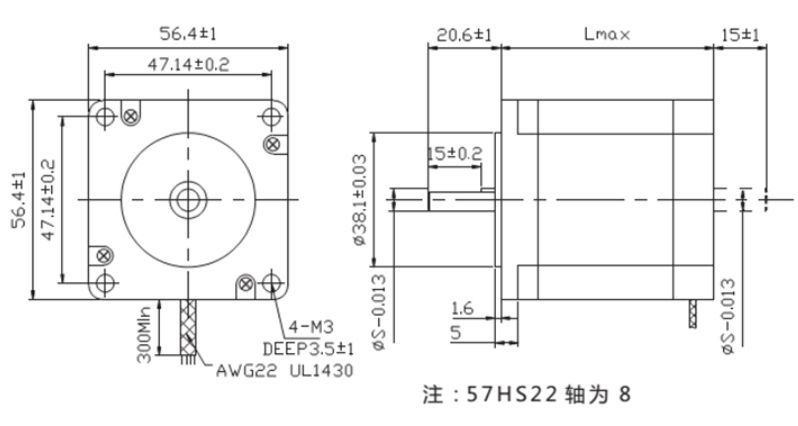

| 57HS22 | concatenation | 1.8 | 2.82 | 1.40 | 6.00 | 2.50 | 520 | 84 | 8 | 4or8 |

| parallel connection | 5.65 | 0.35 | 1.50 | |||||||

| 57HS30 | 1.8 | 2.80 | 2.10 | 10.00 | 3.00 | 650 | 115 | 8 | 4 |

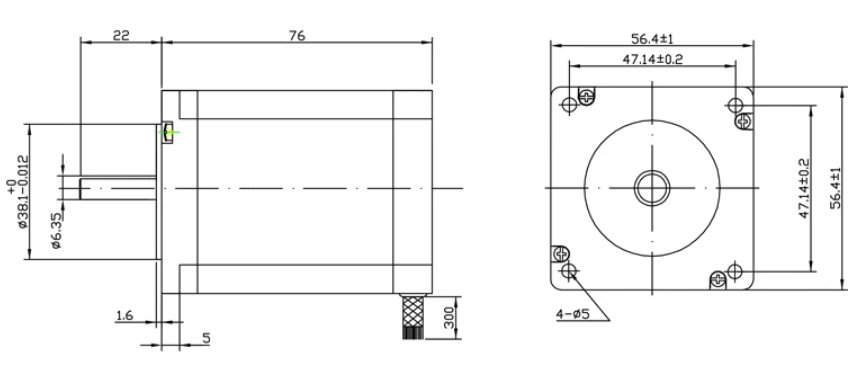

0.98Nm 1.89Nm 2.5Nm 3Nm NEMA23 stepper motor dimensions

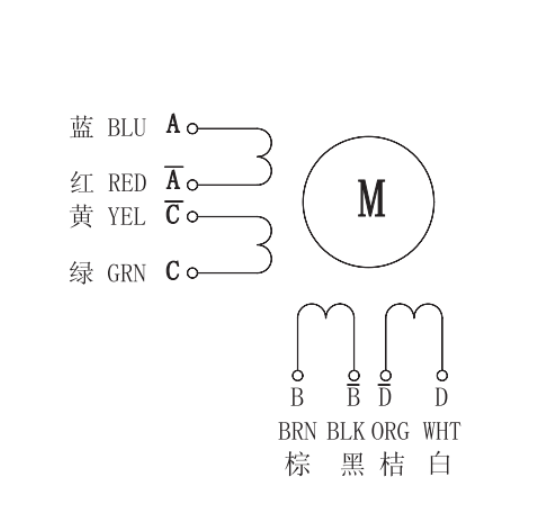

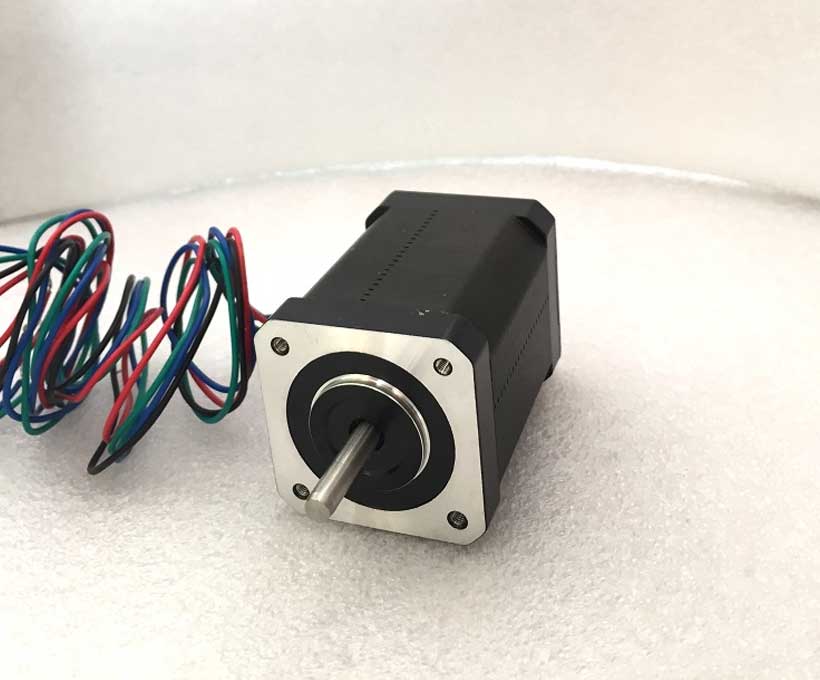

57mm NEMA 23 stepper motor wiring diagram

0.98Nm NEMA 23 stepper motor specifications

The specifications of the 0.98Nm NEMA23 stepper motor are as follows:

Size: 57mmx57mm.

Power: 0.98Nm (140oz-in).

In conclusion, the 0.98Nm NEMA23 stepper motor is a stepper motor with a specific size and power.

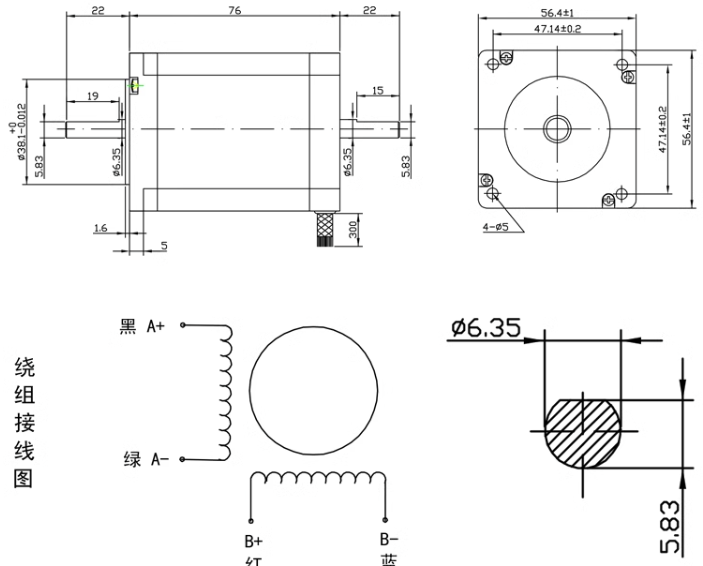

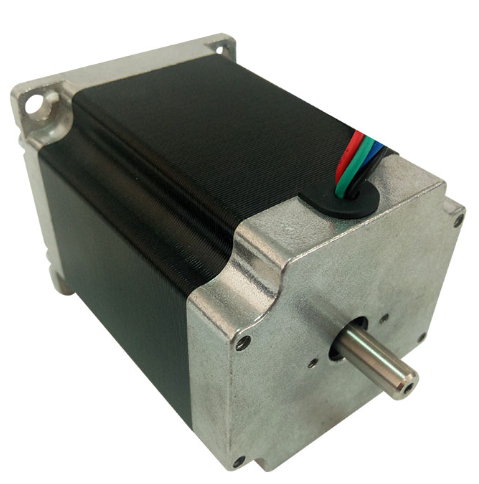

The specifications of the 1.89Nm NEMA23 stepper motor are: motor size 57x57x76 mm, shaft length 13.5 mm, 4 wires, each phase extraction 2.9A.

NEMA23 stepper motor is a common motor commonly used in automation equipment, robots, industrial control and other fields. Its specifications vary depending on factors such as manufacturer, model, power rating, etc.

The specifications of the 2.5Nm NEMA23 stepper motor are as follows:

Voltage: 12V.

Current: 5A.

Torque: 2.5Nm.

Motor size: 57x57x76mm.

Shaft length: 13.5mm.

57mm high torque 1.8Nm engraving machine stepper motor Nema23 single and dual shaft

Number of wires: 4.

Number of phases: 2 phases.

Coil resistance: 2.2 ohms.

Coil inductance: 28mH.

It should be noted that the specifications of different manufacturers and different models of 2.5nm NEMA23 stepper motors may be different, and the specific specifications need to refer to the relevant technical documents or the manufacturer’s product specification sheet.

The specifications of the 3Nm NEMA23 stepper motor are as follows:

Voltage: 12V.

Torque: 3Nm.

Shaft length: 13.5mm.

Number of wires: 4.

Number of phases: 4.

Coil inductance: 28mH.

0.98Nm 1.89Nm 2.5Nm 3Nm NEMA 23 stepper motor specifications – 7630A4D8 stepper motor

It should be noted that the specifications of different manufacturers and different models of 3Nm NEMA23 stepper motors may be different, and the specific specifications need to refer to the relevant technical documents or the manufacturer’s product specification sheet.

Nema 23 1.8Nm stepper motor dual shaft dimensions

Features of a 2-phase NEMA 23 stepper motor

The two-phase NEMA23 stepper motor is a common stepper motor with the following functions:

1. As an executive component, stepper motor is one of the key products of mechatronics and is widely used in various automatic control systems.

57mm x 57mm – Nema 23 stepper motor dimensions

2. How to correctly select a stepper motor, you need to consider torque, load, current, inertia, speed, accuracy and other factors, and clarify these elements of the stepper motor in order to select the right stepper motor suitable for the application.

The application precautions of 2 phase NEMA 23 stepper motor in engraving machine are as follows:

1. Voltage and current: The voltage and current of the 2 phase NEMA23 stepper motor need to be stable to ensure the normal operation of the motor.

2. Drive selection: select the appropriate drive to control the rotation of the stepper motor.

3. Bearing selection: choose a bearing suitable for the stepper motor to ensure that the motor can rotate smoothly in the engraving machine.

NEMA 23 stepper motor, 57 stepper motor, 1.8 degree step angle 56mm body two-phase four-wire

4. Temperature management: the stepper motor will generate heat during operation, and temperature management is required to avoid damage to the motor caused by overheating.

5. Installation method: The installation method of the stepper motor needs to be correct and needs to be fixed firmly to avoid loosening during the operation of the engraving machine.

6. Maintenance and maintenance: regularly maintain and maintain the stepper motor to ensure the normal operation of the motor.

By paying attention to the above matters, it can be ensured that the 2 phase NEMA23 stepper motor can run stably in the engraving machine, and improve the processing accuracy and efficiency of the engraving machine.

Spanish marking machine manufacturers –

The evaluation of 2.5nm stepper motor is as follows:

Performance: The performance of the 2.5nm stepper motor is stable, and it is made of permanent magnet silicon steel sheet and the original bearing of NSK in Japan, which has the advantages of high positioning accuracy, high output torque and fast response speed.

Quality: The quality of the 2.5nm stepper motor is excellent, and it has undergone strict quality control and testing to ensure its long-term stability and reliability.

Application: 2.5nm stepper motor is suitable for various industrial automation equipment, robots, electronic equipment, toys and other occasions that require precise control and fast response.

Price: The price of 2.5nm stepper motor is relatively high, but its high performance and excellent quality ensure its cost performance.

In summary, the 2.5nm stepper motor is a motor with stable performance, excellent quality, wide application and relatively high price.