Precautions for cam splitter selection. Cam splitter is a high-precision rotary device, also known as cam indexer or intermittent splitter.

Precautions for cam splitter selection

It consists of multiple cams, frames, and transmission components that are used to split continuous motion into discrete motions for intermittent motion. Cam splitters have important application value in automated production.

High-precision servo-electric cylinder

Cam splitters have many advantages, here are a few of them:

1: High-speed and smooth operation: the cam splitter is made of alloy steel, after carburizing and other process treatment, HRC hardness above 60 ° precision grinding, and the cam bearing of the output shaft is immersed in engine oil, high speed

Low running wear ensures a long life, continuous operation can reach more than 12.000 hours, no wear.

2: Smooth and stable operation: the cam splitter adopts roller gear type cam splitting mechanism, which has simple structure, high reliability, failure rate close to zero, and is a backlash-free fit.

Precautions for cam splitter selection

3: Accurate repeated positioning: The cam splitter adopts cam input and shaft output, which can provide arbitrary movement, accurate repeated positioning, and the segmentation accuracy is within ±30″, and the high precision can reach ±15″.

4: Easy installation: The cam splitter can be installed at will from different angles, which is very convenient.

5: Wide range of use: Cam splitter has a wide range of use and can be used in various automated production fields.

The selection of cam splitter needs to consider the following factors:

1: The number of indexes: also called the number of workstations, refers to the number of times the machine needs to be indexed. Usually there are 1 station, 2 stations, 3 stations, 4 stations, 5 stations, etc., and the time or angle that requires indexing is increased in turn.

2: The division time or rotation time of each station: that is, the time or angle of each station index, which needs to be selected according to specific needs.

Cam splitter

3: Residence time or stop angle: refers to the time or angle of residence when the machine is indexed, which needs to be selected according to actual needs.

4: The diameter of the working disc: refers to the diameter of the working disc when the machine is indexed, which needs to be selected according to actual needs.

5: The thickness of the disc: refers to the thickness of the working disc when the machine is indexed, which needs to be selected according to actual needs.

6: The material of the disc: refers to the material of the working disc when the machine is indexed, and it needs to be selected according to the actual demand.

7: The weight of the working disc: refers to the weight of the working disc when the machine is indexed, which needs to be selected according to the actual demand.

8: The weight of the fixture: refers to the weight of the fixture when the machine is indexed, and it needs to be selected according to the actual needs.

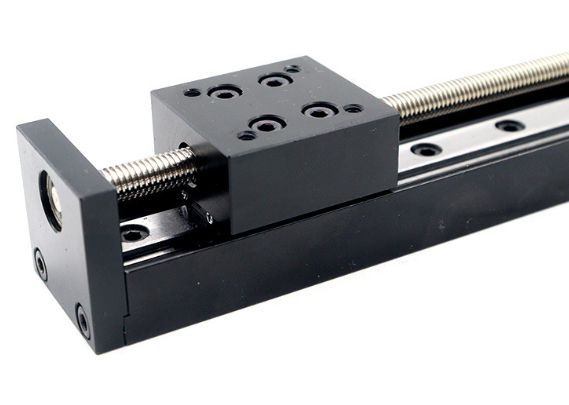

Small rail slide table module workbench

9: Whether the stop position has a top-down impact force: refers to whether the stop position has a top-down impact force when the machine is indexed, which needs to be selected and considered in practice.

10: Whether the bottom of the working disc is supported: refers to whether the underside of the working disc is supported when the machine is indexed, which needs to be selected and considered in practice.

11: Flange cam splitter: This model has a relatively high utilization rate, because it has a large flange plate to fix the disk surface.

12: Platform desktop cam splitter: This model is a bit similar to the flange type, but the platform desktop type has a larger load capacity and a more reliable connection.

The selection of cam splitter needs to carefully consider all aspects, please contact Zhu’s Ant Motor to ensure that the selected cam splitter can meet the actual needs.

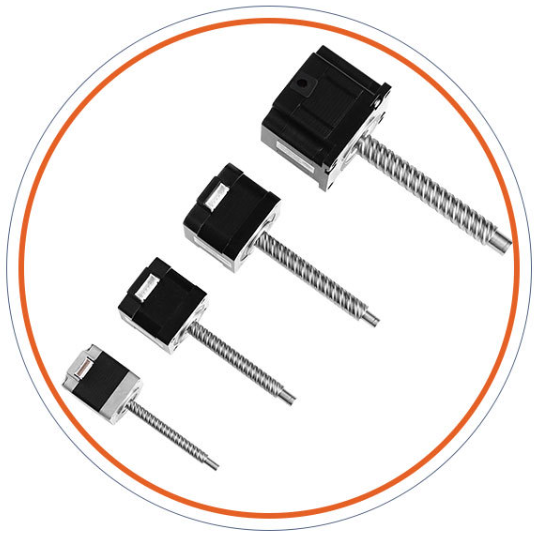

NEMA 11 Stepper Motor – Cross Electric Screw

Cam splitter is a kind of cam mechanism widely used in packaging machines, forming machines, assembly machines, feeding machinery, vending machines, office equipment, automatic machine tools, textile machinery, printing machinery, ceramic machinery, CNC center tool changing mechanism, high-speed pressure machinery, food machinery, logistics machinery, electronic machinery, automation instruments, garment processing machinery, tanning machinery, glass machinery, spring machinery, automobiles and other fields.

Application of cam splitters

Cam splitter has significant advantages such as large transmission torque, compact structure and small size, and is mainly used to replace traditional mechanisms such as pneumatic control maneuver and incomplete gear mechanism.

High-precision screw stepper motor for industrial machine tools

In the fields of pharmaceutical machinery, food packaging machinery, glass machinery, food packaging machinery, glass machinery, ceramic machinery, etc., these automated machines are used as tools to convert continuous operation into stepping actions.

With its own space cam rotation, functions such as intermittent transmission on the linear defense line in the circumferential direction and swing drive manipulator can be realized in various automatic machines. Very small splitters contain the input and output shafts driven by the motor, and the turntable is usually mounted on the output shaft.

While widely used, we also want to use cam splitters of various automated machinery, remember to do a good job of product maintenance and maintenance.