NEMA 23 Closed-Loop Stepper Motor – 57mm standard hybrid stepper motor with encoder. China Servo Motion Control Company provides stepper and servo motor products of various flange sizes.

What is nema 23 stepper motor?

The NEMA 23 stepper motor is characterized by a hybrid structure, that is, the stator is a permanent magnet and the rotor is a coil, and the magnetic field generated by the coil is controlled by controlling the current to rotate the rotor.

At the same time, the motor also adopts hysteresis synchronous structure, which can improve the accuracy and stability of the motor.

NEMA 23 Closed-Loop Stepper Motor Nomenclature

|

MY

|

42

|

CM

|

L

|

05

|

D

|

8

|

–

|

XX

|

|

brand

|

flange

|

type

|

Encoder resolution

|

Torque

|

Out of the shaft

|

Shaft diameter

|

Non-standard parameters

|

|

|

RFIDEPC.COM

|

20:nema 8

28:nema 11 42:nema 17 |

CM: Hybrid servo motor |

L: Encoder resolution 1000 lines

H: Encoder resolution 2500 lines |

05: The holding torque is 0.5N.m

08: The holding torque is 0.8N.m |

A: Round shaft output

D: Unilateral washing U: Wash the keyway |

4:4mm

5:5mm 8:8mm |

Custom codename

|

NEMA 23 Closed-Loop Stepper Motor Specification sheet for NEMA 23 standard hybrid stepper motor with encoder

nema 23 stepper motor datasheet – closed loop stepper motor nema 23

|

Model

|

Encoder resolution | Motor length (mm) | Hold torque (N.M) | Rated current (A) | Rotor moment of inertia (g.cm²) | Motor weight (kg) |

Encoder output circuit

|

Encoder origin signal | Drivers are fitted as standard |

|

MY57CML12-D8

|

1000CPR

|

(56+22)78

|

1.2

|

4.0

|

220

|

0.85

|

Differential input

|

NO | Hybrid servos

Pulse type MY57CDL

MY57CDH |

|

MY57CMH12-D8

|

2500CPR

|

Yes | |||||||

| MY57CML20-D8 |

1000CPR

|

(76+22)98

|

2.0

|

5.0

|

420

|

1.30

|

Differential input

|

NO | |

| MY57CMH20-D8 |

2500CPR

|

Yes |

★ Drive options: pulse triggering, IO programming, RS485 communication, CANopen communication, EtherCAT communication.

★ For related 2D, 3D drawings, please contact Shenzhen Intelligent Servo Motion Control Co., Ltd. (servosteppersupplier@gmail.com) sales staff.

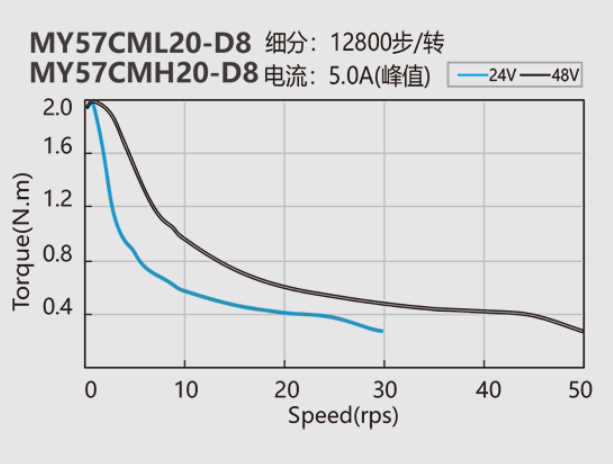

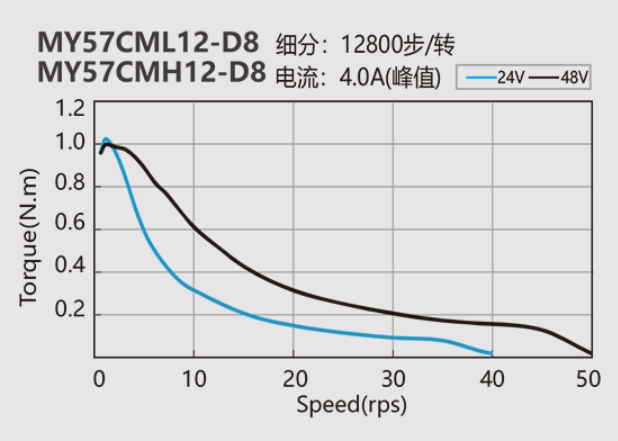

NEMA 23 closed-loop stepper motor MY57CML12-D8 speed torque curve

NEMA 23 MY57CML12-D8 closed-loop stepper motor speed torque curve

NEMA 23 closed-loop stepper motor MY57CML12-D8 speed torque curve

57mm hybrid servo motor – NEMA 23 Closed-Loop Stepper Motor – 57mm standard hybrid stepper motor with encoder

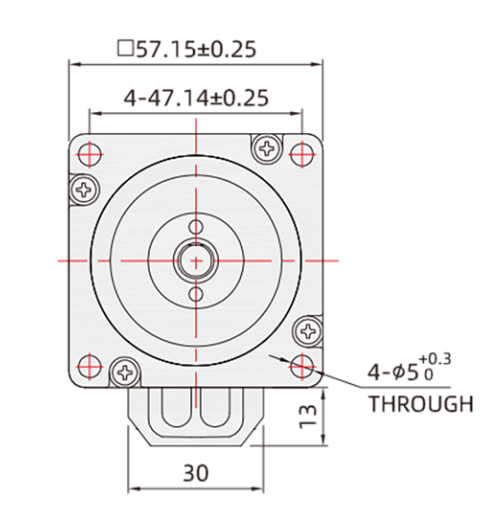

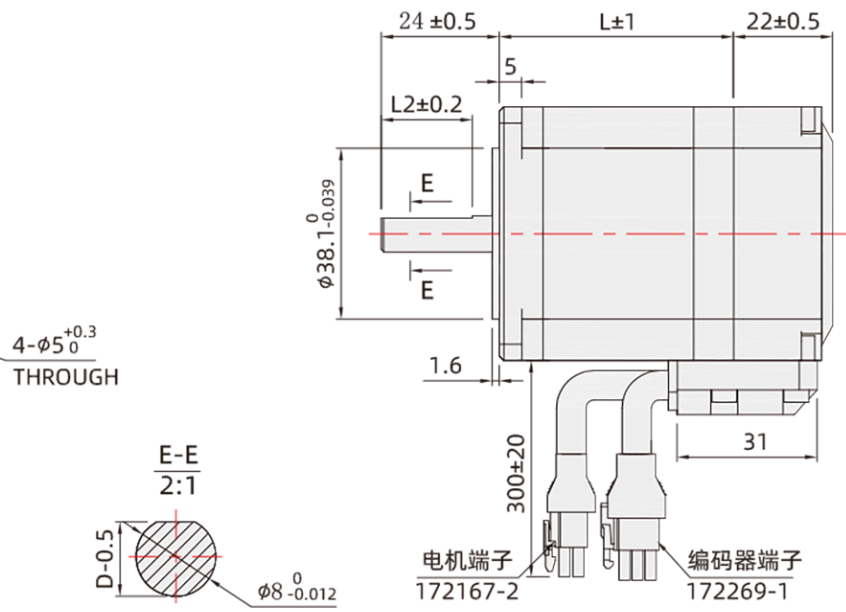

NEMA 23 closed-loop stepper motor flange dimensional drawing – nema 23 stepper motor wiring diagram

57mm stepper motor with encoder – Nema 23 stepper motor dimensions

How to install brushless motors – closed-loop stepper motors (built-in encoders)?

Nema 23 MY57CML12-D8 closed-loop stepper motor, Nema 23 MY57CMH12-D8 closed-loop stepper motor, Nema 23 MY57CML20-D8 closed-loop stepper motor, NEMA 23 MY57CMH20-D8 closed-loop stepper motor instructions, the specific steps are as follows:

1. About the installation direction of the motor: The installation direction of the motor can be installed freely in either direction, horizontally, upward, and downward. Pay attention to the suspension load and axial load of the shaft regardless of the direction.

2. In addition, please be careful not to let the cable contact with the installation surface, causing unnecessary pressure.

3. NEMA 23 hybrid servo motor installation method: please try to consider the problem of heat dissipation and vibration prevention, firmly fix it on the strong metal surface, be sure to use the front end of the motor installation stop positioning, and pay attention to the tolerance to strictly ensure the concentricity of the motor output shaft and the load.

4. The peak current setting of the driver must be less than the rated current of the motor.

5. Do not carry the motor cable directly.

57mm stepper motor with encoder product application field:

Solid crystal machine, wire bonding machine, UV printer, 3D printer, inkjet printer, plotter, embroidery machine, dispensing machine, winding machine, solder paste printing machine, PCB drilling machine, V-CUT machine target machine, FPC reinforcement machine, coating machine, laminating machine, IC sorting machine, glue filling machine, soldering machine BGA rework table, woodworking engraving machine, laser engraving machine, IC burning machine, connector assembly machine, SMT peripheral equipment, taping machine, medical equipment, marking machine, labeling machine, laminating machine, placement machine, heat pressing machine, backlight film machine, coating machine, reciprocating machine, terminal machine, wire stripping machine, non-standard equipment, XYZ measuring instrument, etc.

NEMA 23 Closed-Loop Stepper Motor – 57mm standard hybrid stepper motor with encoder

To illustrate the NEMA 23 hybrid servo motor, the NEMA 23 hybrid servo motor example is:

INSTAR electromechanical YSD254-RA4-S 56mm NEMA23 stepper motor, 57 NEMA23 stepper motor all-in-one machine produced by Changzhou Jingkong Motor Electrical Co., Ltd.

What is the difference between NEMA 23 Hybrid Stepper Motor with Encoder and NEMA 17 Hybrid Stepper Motor with Encoder?

The differences between NEMA 23 stepper motor with encoder and NEMA 17 stepper motor with encoder are as follows:

1. The external dimensions are different: the stepper motor of NEMA 17 has an external dimension of 42 mm, while the stepper motor of NEMA 23 has an external dimension of 57 mm.

nema 23 stepper motor datasheet – closed loop stepper motor nema 23

2. The torque is different: the stepper motor torque of NEMA 17 is 0.36Nm, while the stepper motor torque of NEMA 23 is 0.55Nm.

3. The price is different: the price of the stepper motor of NEMA 17 is relatively low, while the price of the stepper motor of NEMA 23 is relatively high.

nema 23 closed loop stepper motor kit

4. Different application scenarios: NEMA 17’s stepper motor is suitable for low-power, high-precision automation equipment such as electronic equipment, medical equipment, textile machinery, etc., while NEMA 23’s stepper motor is suitable for high-power, high-torque automation equipment such as various automation equipment, robots, CNC machine tools, etc.

In summary, there are differences between the two in terms of encoder, external size, torque, price and application scenarios.

Russian CNC manufacturer –

Thanks for the NEMA 23 stepper motor datasheet, the product is very good.