Can stepper motors be used on dough sheeters? What is the specific plan? Stepper motors can be used on dough sheeters to control the pressing and transfer of dough.

Can stepper motors be used on dough sheeters? What is the specific plan?

The following is the specific scheme of the stepper motor on the dough sheeter:

1. Stepper motor selection: First of all, it is necessary to determine the load characteristics of the dough sheeter, including speed, torque, accuracy and other requirements, and then select the suitable stepper motor according to these requirements.

According to the load characteristics, the appropriate stepper motor driver and controller can be calculated to ensure the operation stability and reliability of the stepper motor.

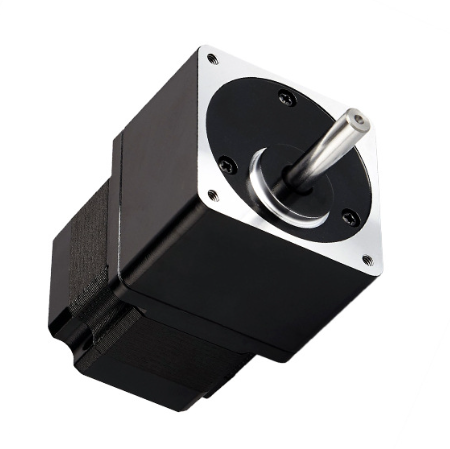

Shinano 2 phase DC S60D120A-MACR6S2 integrated reduction stepper motor 60mm small size and high precision

2. Electrical control system design: connect the stepper motor, drive and controller to each other, and add sensors and safety switches and other equipment to ensure the safety and stability of the dough sheeter. Need to consider the reliability and flexibility of the electrical control system, you can use PLC control system or single-chip microcomputer control system, according to the specific application scenario to choose.

1Nm 120W 2-phase 500rpm 1 degree DC 1:3.6 reduction ratio stepper motor

3. Mechanical transmission system design: For the mechanical transmission system of the dough sheeter, it is necessary to design suitable rotating parts and transmission parts according to the working principle and requirements of the dough sheeter. Gears, chains, belts and other transmission methods can be used to transfer the rotation of the stepper motor to the dough pressing parts, and transfer the dough from the cutting machine to the conveyor belt or roller of the dough sheeter.

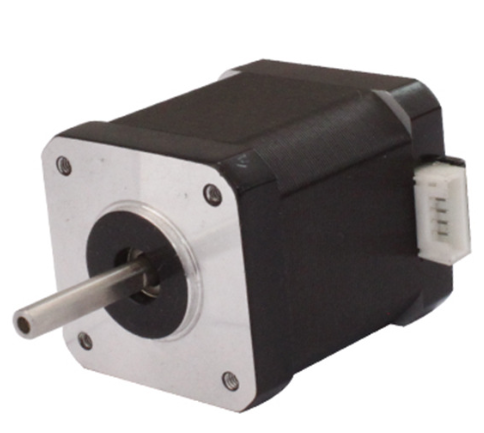

China Changzhou Stepper Motor Manufacturer – 1.8° NEMA 17 High Precision Stepper Motor – Special Stepper Motor for Syringe Pump

4. Control program writing: write the control program to realize the speed and direction control of the stepper motor, and also need to add functions such as exception handling and fault diagnosis according to the specific situation to ensure the safety and stability of the dough sheeter.

5. Testing and optimization: After completing the above design and programming, the dough compactor needs to be tested and optimized to ensure that it meets the requirements. Various test tools and equipment, such as oscilloscopes, multimeters, motor testers, etc., can be used to test and analyze the performance of stepper motors and dough sheeters, and find and fix problems.

China two-phase DC NEMA 24 integrated reduction stepper motor

In short, the application of stepper motor in the dough sheeter needs to comprehensively consider the problems of mechanical transmission, electrical control, programming, etc., and it is necessary to design a scheme that meets the needs according to the specific requirements, and test and optimize it to ensure the performance and stability of the dough sheeter.

Where is the stepper motor used in the dough sheeter?

Stepper motors are used in the transmission mechanism of the dough sheeter to control the pressing and transfer of dough.

Stepper motor is used in the dough sheeter, how should the program be designed?

When designing the procedure of a stepper motor on a dough sheeter, the following steps need to be considered:

1. First determine the control mode of the stepper motor, such as using the full-step mode or the half-step mode.

2. According to the specific workflow of the dough sheeter, determine the rotation angle and speed of the stepper motor, and write the corresponding control program.

28mm NEMA 11 linear screw stepper motor

3. Set the corresponding parameters in the program, such as acceleration, deceleration, uniform speed, etc., to achieve the smooth start and stop of the stepper motor.

4. Considering the actual working situation of the dough sheeter, corresponding protective measures need to be preset in the program, such as overload protection, undervoltage protection, etc.

500rpm 1Nm 120W 24-48V two-phase 1 degree DC 1:3.6 reduction ratio stepper motor

5. Finally, verify the effectiveness and reliability of the program through experiments, and optimize and adjust the program according to the experimental results.

In short, when designing the program of the stepper motor on the dough sheeter, it is necessary to combine the actual situation and specific needs, adopt scientific methods and tools, and refine and optimize to ensure the correctness and reliability of the program.