Common fault causes and solutions of RS485 communication interface of PLC

1. Common fault symptoms

When the RS-485 port of PLC is connected to the computer through the non-isolated PC/PPI cable, the connection between PLC and PLC, or the communication between PLC and inverter, touch screen, etc., the communication port damage phenomenon occurs from time to time, and the more common damage conditions are as follows:

NEMA 23 stepper motor manufacturers – Common fault causes and solutions of RS485 communication interface of PLC

(1) R1 or R2 is burned out, Z1, Z2 and SN75176 are intact. This is due to the large transient interference current through R1 or R2, bridge rectification, Z1 or Z1 to ground, Z1, Z2 can withstand the impact of a maximum of 10A current, and the transient power generated by this current on R1 or R2 is: 102×10=1000W, of course, it will be burned out.

(2) SN75176 is damaged, R1, R2, Z1, Z2 are intact. This may be mainly caused by electrostatic shock or transient overvoltage faster than the action speed of Z1 and Z2, static electricity is everywhere, and only human body mode will also generate static electricity of ±15kV.

(3) Z1 or Z2, SN75176 are damaged, R1 and R2 are intact. This may be due to transient interference voltages of high voltage and low current that break down Z1 or Z2 and SN75176, and R1 and R2 do not heat up and burn out due to the small current and short generation time.

2. Analysis of the cause of the failure

From the analysis in 1, it is known that the main reason for the damage of the PLC interface is caused by transient overvoltage and static electricity, and the causes of transient overvoltage and static electricity are many and complex, such as due to the common ground of the PLC internal 24V power supply and 5V power supply, the output terminals L+, M of the 24V power supply for other equipment may cause ground potential changes, resulting in common-mode voltage beyond the allowable range. Therefore, the EIA-485 standard requires that the signal ground of each RS485 interface be connected together with a low-resistance wire to ensure that the ground potential of each node is equal and eliminate ground circulation.

(1) When plugging and unplugging the unisolated connecting cable with electricity, due to the presence of many inductors, capacitors and other devices in the circuits with unequal potentials at both ends, transient overvoltage or overcurrent will inevitably occur at the moment of plugging and unplugging. Based on this consideration, when plugging and unplugging the communication connector, try to keep the device in a power-off state.

(2) Transient overvoltage or overcurrent generated by other devices connected to the RS-485 bus will also flow into the PLC, and the more devices connected to the bus, the more factors that generate transient overvoltage.

(3) When the communication line is long or there is an outdoor overhead line, lightning is an interference that must be considered. Lightning is a major source of natural interference, and the interference generated by lightning can be transmitted thousands of kilometers away. The time-domain waveform of lightning interference is superimposed into a large spike pulse on the background of a random pulse, and this huge energy spike pulse will inevitably cause overvoltage on the line, causing damage to equipment connected to the PLC and other communication networks, which should be avoided or reduced to reduce the degree of damage and reduce losses.

NEMA 23 stepper motor for 3D printer – plc control system

3. PLC Solution

I. Consider from within the PLC

(1) Using isolated DC/DC to isolate 24V power supply and 5V power supply, we analyzed Mitsubishi, Omron, Schneider PLC, and Siemens’ ProFibus interface

(2) Choose high-grade RS-485 chips with electrostatic protection, overheating protection, input failure protection and other protection measures, such as: SN65HVD1176D, MAX3468ESA, etc., the price of these chips is generally in the tens to tens of yuan, and the price of SN75176 is only 1.5 yuan.

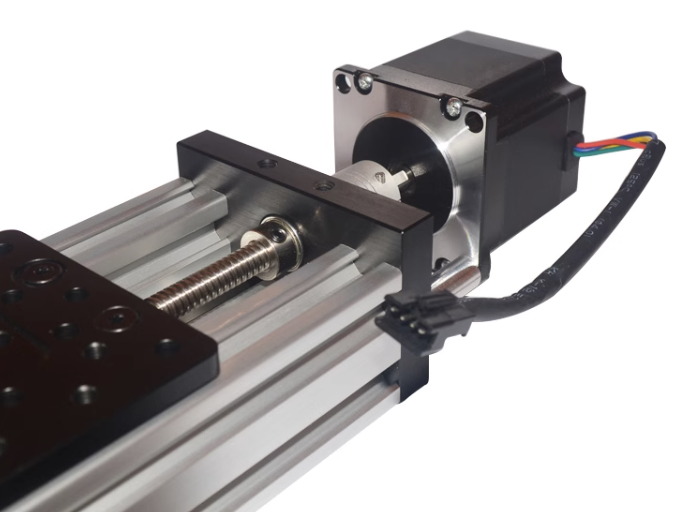

NEMA 17 screw slide stepper motor

(3) The use of new protection devices TVS or BL surge absorbers with faster response speed and greater transient power, such as P6KE6.8CA clamping voltage of 6.8V, withstand transient power of 500W, BL devices can resist more than 4000A high current impact. If a chip without fault protection is used, such as the SN75176, some processing can be done in the software to avoid communication exceptions. That is, before entering normal data communication, the bus is driven by the host to greater than +200mV in advance and held for a period of time so that the receivers of all nodes produce high-level outputs. In this way, when valid data is emitted, all receivers can correctly receive the start bit and thus receive the complete data.

(4) R1 and R2 use positive temperature coefficient self-recovery insurance PTC, such as JK60-010, the resistance value under normal conditions is 5 ohms, does not affect normal communication, when the surge impact, large current flows through PTC and protection device TVS (or BL), PTC resistance value will increase suddenly, so that the surge current rapidly decreases.

The nema 17 stepper motor is used in 3D printers – engraving machines – How to choose a stepper motor according to the specific situation?

II. Consider from outside the PLC

(1) Use isolated PC/PPI cables, and try not to use cheap non-isolated cables (especially in industrial sites). The PC/PPI cable (6ES7901-3BF00-0xa0) produced by Siemens in the early days was not isolated, and now it is also changed to isolated cable.

(2) PLC’s RS-485 port adopts isolated bus connectors, such as PFB-G, with a rate of 0~1.5Mbps and automatic adaptation, and the appearance and use method are the same as Siemens’ non-isolated bus connection.

(3) Third-party equipment connected to the PLC, such as inverters, touch screens, etc., RS-485 ports are isolated using RS-485 isolator BH-485G, so that there is no “electric” connection between RS-485 nodes, and there is no ground circulation generation, even if one node is damaged, it will not be damaged by other nodes.

(4) Good grounding is an important condition for the safe and reliable operation of industrial control systems, especially for industrial communication networks. In an industrial communication network, there are at least three separate ground wires, grounded by a point.

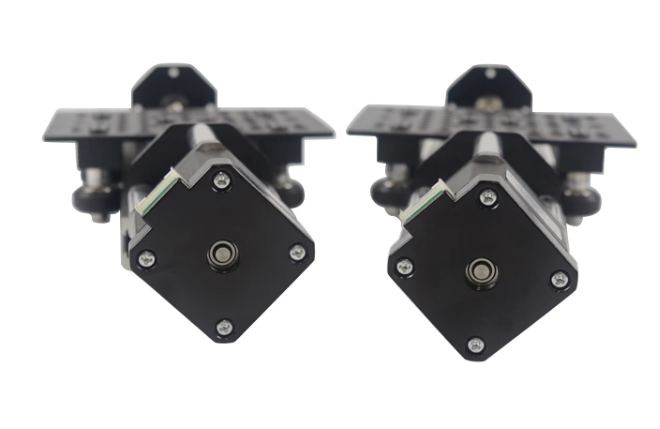

Soft metal engraving machine stepper motor

The first is the low-level circuit ground (that is, the signal ground), including digital ground, analog ground, signal ground and DC ground; The second is the noise ground wire, that is, the ground wire of relays, motors, and high-power circuits; The third is the casing grounding point, which is specially used for the mechanical shell, fuselage, rack, and site, and this ground wire should be connected to the ground wire of the AC power supply. The AC power ground wire should be connected to the protective ground wire to avoid interference caused by the uneven position of each point of the announced ground wire. The RS-485 communication line adopts a dedicated shielded cable for the Profibus bus to ensure that the shielding layer is connected to the shell of each device and finally connected to the earth.

(5) For systems with overhead lines, it is best to set up special lightning protection facilities on the bus.