Industrial servo drive and control system industry development trend and opportunities

1. Industry overview

Industrial servo drive and control system refers to the displacement, speed, angle and other control of the object composed of an automatic control system, which can track any change of the target, is an extended product based on frequency conversion technology, which can not only carry out speed, torque control, but also achieve accurate, fast and stable position control.

Industrial servo drive and control system is mainly composed of servo drive, servo motor and encoder.

The servo drive is responsible for breaking down the information received from the controller into commands that can be executed by a single degree-of-freedom system, which are then passed on to the actuator (servo motor);

Industrial servo drive and control system industry development trend and opportunities – Precision metering pump servo motor driven pump plunger type

The servo motor converts the received current signal into torque and speed to drive the control object to realize the control of each joint angle, angular velocity and joint torque; As a feedback device of the servo system, the encoder largely determines the accuracy of the servo system.

The encoder is installed on the servo motor, rotates synchronously with the motor, and sends the encoded signal back to the controller while rotating, and the controller determines the steering, speed, and position information of the servo motor.

The servo system can be divided into hydraulic servo system, electric servo system and pneumatic servo system according to the different actuators, and the most widely used is the electrical servo system.

The electrical servo system can be further divided into DC servo system and AC servo system. Among them, DC servo motors can achieve precise and fast start or stop functions, so they are mostly used in equipment that can be controlled by microcontrollers or computers.

AC servo motor contains encoder, together with the controller to provide closed-loop control and feedback, its working voltage is higher, torque is higher, higher precision, mainly used in robots, automation equipment and other mechanical equipment.

(1) Servo drive

Servo drive is a device that realizes high-precision transmission system positioning by controlling servo motor, is the center of signal conversion and signal amplification in the servo drive and control system, by synthesizing and amplifying the input signal and feedback signal, according to the different polarity of the comprehensive signal, output the corresponding signal to control the forward rotation or reverse rotation of the servo motor; When the input signal is balanced with the feedback signal, the servo motor stops rotating and its end actuator stabilizes in a specific position.

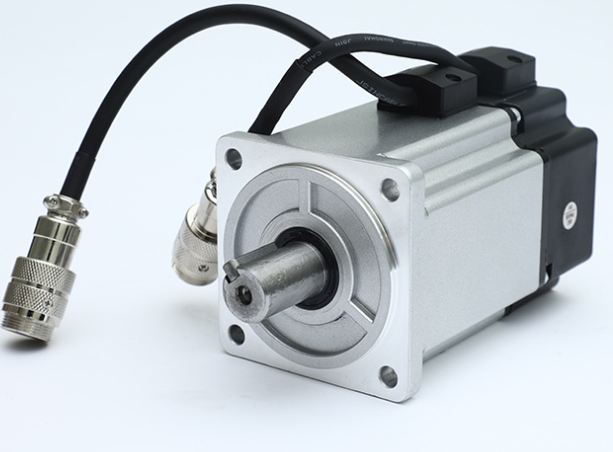

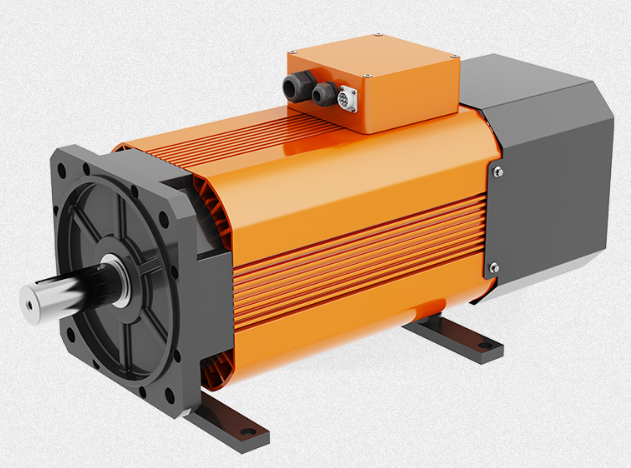

(2) Servo motor

As an executive component in the servo drive and control system, the servo motor is used to convert the signal of the servo drive into the angular displacement and angular velocity of the motor rotation.

The servo motor is mainly composed of a stator and a rotor, the stator is equipped with an excitation winding and a control winding, and the rotor inside it is a permanent magnet or induction coil, and the rotor rotates under the action of the rotating magnetic field generated by the excitation winding.

Servo motors are divided into two categories: DC servo motors and AC servo motors, unlike ordinary motors, servo motors are usually integrated with encoders to achieve closed-loop control and precise control. The performance indicators of servo motors have obvious advantages over ordinary motors in terms of overload capacity, speed regulation range and response speed.

2. Industry development trend

At present, industrial servo drive and control system is developing in the direction of digitalization, miniaturization, intelligence and high performance, and is mainly manifested in the following aspects:

(1) AC servo control technology

AC servo control technology will become the main development direction of industrial servo drive and control system, and towards high performance, full digitalization, intelligence and software direction, this type of servo system includes speed loop control, position loop control and current loop control three systems, and can complete internal communication through application software, which will become the mainstream direction of AC servo system development.

PLC program servo control forum- servo motor control forum

(2) Intelligent power integrated circuit

The power electronic equipment used in the industrial servo system will continue to develop to high frequency, intelligent power integrated circuit will be further widely used, because the integrated circuit has the advantages of small area, high reliability, easy integration and long service life, can be the traditional controller and other difficult to accurately control the module using integrated circuit to achieve, the use of digital and analog combined methods to further improve its accuracy and the stability of the entire system.

3. Opportunities faced

(1) Intelligent manufacturing continues to drive market demand growth

In recent years, the Internet of Things, 5G, cloud computing, big data, artificial intelligence, intelligent driving and other emerging technology fields have gradually begun to commercialize and industrialize, which will effectively promote the intelligent manufacturing process of industrial production, promote the development of China’s manufacturing industry in the direction of intelligence, flexibility, increase production and sales, and reduce operating costs, and then drive the continuous growth of market demand for automation products in the field of industrial servo drives and control systems.

To purchase servo motors, servo drives, stepper motors and more, please contact us WhatsApp: +8618062443671

(2) The level of domestic production continues to improve and promote import substitution

With the continuous improvement of the technical level of domestic automation equipment manufacturers, the localization rate of China’s industrial servo drive and control system field continues to increase. Since 2010, local enterprises have successively landed in the capital market, their comprehensive strength has been greatly enhanced, and the industry has entered a period of rapid development.

Compared with foreign brands, local brands are closer to the actual needs of domestic customers, provide more timely service responses, and continuously increase market share.

Industrial servo drive and control system industry development trend and opportunities – servo motor manufacturers in China

(3) Downstream application fields continue to expand and update

Industrial servo drive and control system are widely used in various fields of the national economy, such as building materials, papermaking, machine tools, elevators, chemical industry, metallurgy, coal, textile machinery, plastic machinery, printing machinery, packaging machinery, food and beverage machinery and other traditional fields, as well as electronic manufacturing equipment, industrial robots and other emerging industries.

In addition, automation products in the field of industrial servo drive and control system are also widely used in emerging fields such as urban rail transit, electric vehicles, and new energy power generation, which not only effectively meet the incremental market demand generated by the expansion of emerging industries, but also continue to meet the market stock demand with the development and renewal of traditional industries.

Source: PwC Youcze

For more industry information, please refer to PwC Consulting’s “2022-2028 Industrial Servo Drive and Control System Industry Segment Analysis and Investment Prospect Special Report”, while PwC Consulting also provides industry research reports, industry chain consulting, project feasibility reports, 14th Five-Year Plan, BP business plans, industry maps, industrial planning, blue white papers, IPO fundraising and investment feasibility studies, IPO working paper consulting and other services.

stepper motor manufacturers in China