The solution of stepper motors in the field of precise control of pharmaceutical filling machines. Research on precise control technology of pharmaceutical filling machine based on stepper motor.

The solution of stepper motors in the field of precise control of pharmaceutical filling machines

1. Introduction

Pharmaceutical filling machine has an important position in the pharmaceutical industry, and has high requirements for its operation accuracy and speed. The use of stepper motor to automatically control the pharmaceutical filling machine can improve the equipment performance and production efficiency. This article discusses how to realize the automatic control of stepper motors using stepper motors in pharmaceutical filling machines from the perspective of engineering developers.

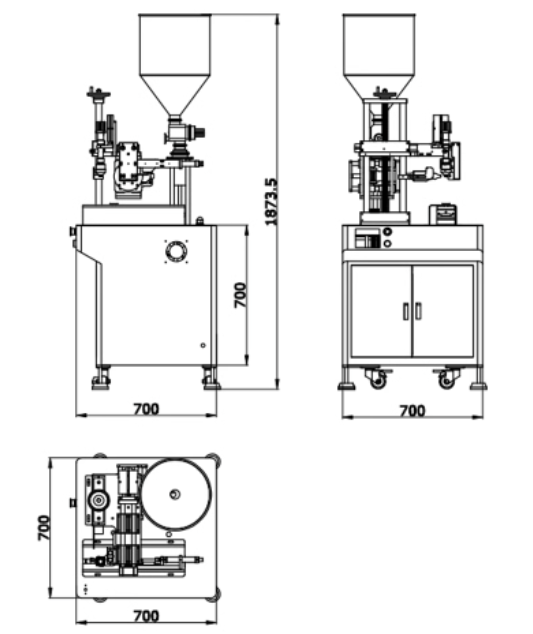

Small semi-automatic filling and sealing machine – liquid composite hose cosmetic medicine filling machine

2. System composition

The automatic control system of pharmaceutical filling machine using stepper motor is mainly composed of the following parts:

(1) Stepper motor and driver;

(2) sensors and actuators;

(3) Host controller (such as single-chip microcomputer or PLC);

(4) Man-machine interface (such as touch screen);

(5) Electrical components and power supply.

3. System design principles

When designing the automatic control system of the stepper motor for the pharmaceutical filling machine, the following principles should be followed:

(1) High integration: close integration of all parts to reduce system volume and reduce costs;

(2) Easy maintenance: the system structure is simple, easy to maintain and troubleshoot;

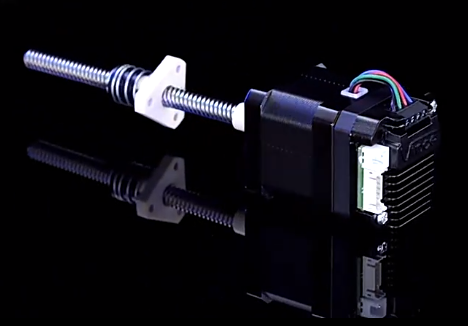

Linear precision screw stepper motor factory direct supply

(3) Reliability: the use of components with high reliability to ensure the long-term stable operation of the system;

(4) Extensibility: It has good scalability, which is convenient for later upgrades and function expansion.

4. System function module

According to the functional requirements of the pharmaceutical filling machine, the automatic control system is divided into the following modules:

(1) Measurement module: use sensors to measure the flow, pressure and other parameters of the filling liquid in real time to provide real-time data for the control system;

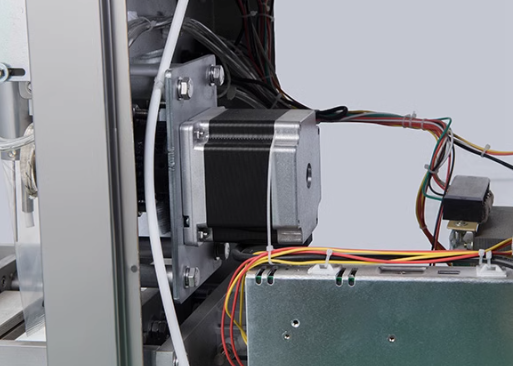

nema 17 nema 34 nema 23 stepper motor

(2) Motion control module: responsible for controlling the speed and steering of the stepper motor to realize the precise operation of the filling machine;

(3) Human-computer interaction module: through touch screen and other equipment to achieve interaction with the operator, convenient for equipment parameter adjustment and troubleshooting;

(4) Data processing module: realize data collection, processing and storage, provide real-time operation status and historical data query functions;

The semi-automatic small filling and sealing machine is controlled by a stepper motor

(5) Safety protection module: monitor system abnormalities and realize fault alarm and protection functions.

5. System implementation process

(1) Select suitable stepper motors and drives to meet the load, resolution and performance requirements of pharmaceutical filling machines;

(2) Design a suitable main controller hardware circuit to ensure the stable operation of the controller;

Stepper motor is used in automatic filling machine, beer medicine, oral liquid, disinfectant filling equipment

(3) Develop software programs to realize measurement, motion control, and human-computer interaction.

Pharmaceutical filler control solutions include the following:

Ethernet connected to the control plane.

Compact controller JC-365MC with motion control.

Modular JX3 system.

Conveyor belts.

Up to 16 servo axes.

JM-10xx。

PronetEthernet/IP fieldbus connection.

It is particularly suitable for aseptic filling of aseptic products.

Product changes can be done quickly and at any time.

Semi-automatic small filling and sealing machine – pharmaceutical filling machine uses stepper motor

Easy format changeover via dynamic switching of electronic cam discs.

There are several methods to control the filling volume of liquid filling machine:

1. Manual adjustment. It needs to be carried out by personnel with operating experience, and the adjustment can only be made to the general capacity, and it also needs to be accurately measured with a measuring cup.

2. Electric or computerized adjustment. The equipment is equipped with a non-digital display capacity panel, only the stainless steel measuring cup is excellent and reasonable, the error is within the specification, and there is no need for measuring cup.

3. Overall adjustment. All filling valves of the liquid filling machine adjust the volume consistently, and are equipped with a capacity display, which is easy to control in operation.

Application of stepper motor in automatic liquid packaging machine

4. Adjust independently. Each filling valve on the equipment needs a single adjustment, the capacity scale is a reference, and the measuring cup calculation measurement adjustment is generally required.