What is the difference between stepper motor and brushless motor? Stepper motors can also be said to be brushless motors. Stepper motors do not have commutation carbon brushes, but a specific title, while brushless motors are a general title.

What is the difference between stepper motor and brushless motor?

First of all, the stepper motor is an actuator that converts the electrical pulse into angular displacement, and the rotation angle and speed of the stepper motor can be controlled by controlling the number and frequency of the pulse.

What is the difference between stepper motor and brushless motor – What is the difference between stepper motor and brushless motor?

The brushless motor is a motor that rotates the motor through an electronic commutator, without the use of mechanical carbon brushes.

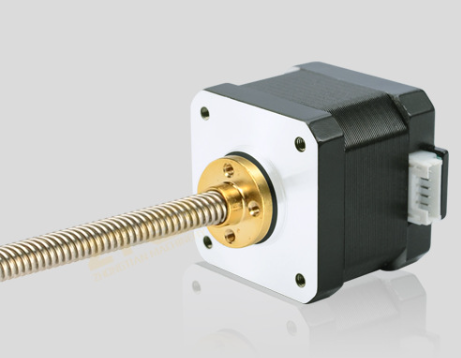

3D Printer Engraving Machine DC Brushless Stepper Motor – Ball screw Stepper Motor

Secondly, in terms of structure, the rotor of the stepper motor is stationary, only the stator rotates; The rotor and stator of brushless motors are rotating.

Thirdly, in terms of working principle, stepper motors control the rotation angle and speed by controlling the number and frequency of pulses; The brushless motor rotates the motor through an electronic commutator.

Finally, in terms of performance, brushless motors have higher speed and torque than stepper motors, and they are also more efficient.

In short, there are obvious differences in structure, working principle and performance between stepper motors and brushless motors, and it is necessary to choose the right motor according to actual needs.

Is a brushless motor a DC motor?

Brushless motor is a kind of AC motor, is a kind of three-phase AC permanent magnet motor, input model brushless motor 3 wires of the current is alternating current, but this AC is not 50HZ mains sine wave, but from the brushless motor controller (commonly known as brushless ESC) modulated three-phase alternating rectangular wave, the frequency is much higher than 50HZ, and changes with the motor speed.

What are the types of brushless motors?

The types of brushless motors are:

1. DC brushless motor: using external supply or internal supply, the structure is relatively simple, the operation is safe and reliable, the service life is long, the maintenance is simple, and it is a necessary component of many equipment.

2. AC brushless motor: provides higher output power, longer service life, higher power factor, lower operating noise, and is a necessary component in many new equipment.

42 Stepper Linear Motor – 3D Printer Engraving Machine DC Brushless Stepper Motor – Ball screw Stepper Motor

3. Frequency conversion brushless motor: it can realize the speed adjustment of the motor, improve the sensitivity of the motor, make the motor more accurate control of the motion state of the equipment, and is a necessary component of many high-precision equipment.

4. Servo brushless motor: the feedback technology is adopted, which can detect and control the operation of the motor more accurately, so that the motor can control the motion state of the equipment more accurately, which is a necessary component for many equipment requiring high precision.

5. Permanent magnet brushless motor: the use of permanent magnet technology can realize the intelligent control of the motor, so that the motor can detect and control the motion state of the equipment more sensitively, which is a necessary component of many intelligent equipment.

6. Vector brushless motor: the use of vector technology can realize the high-precision control of the motor, so that the motor can detect and control the motion state of the equipment more accurately, which is a necessary component of many high-precision equipment.

Ball screw Stepper Motor – nema 17 Stepper Linear Motor – DC Brushless Stepper Motor

Examples of brushless motors are:

1. Home appliances: People have long used washing machines and air conditioners. Recently, brushless motors have also been used in electric fans, and this has succeeded in significantly reducing power consumption.

2. Vacuum cleaner: By changing the control system, the number of rotations has increased significantly.

3. Hard disk: its rotating part adopts brushless motor. Since it is a motor that needs to run for a long time, durability is important. Of course, it also has the purpose of trying to curb electricity consumption.

4. Small robots: Brushless motors will be widely used in small robots, especially in “service robots” that provide services in areas other than manufacturing.

Is the stepper motor DC or AC? Which motor is better?

In the stepper drive system there is DC and AC, mainly refers to the power supply to the stepper driver is DC or AC, such as EZM872 input power supply is 20~80VDC, that is, DC stepper drive system, but such as EZM872H input power supply is 18~80VAC, that is, AC stepper drive system.

Ball screw Stepper Motor – DC Brushless Stepper Motor

Generally speaking, the current flowing through the motor winding is DC is DC motor, if the current flowing through the winding is AC is AC motor, but as far as the stepper motor is concerned, the current flowing through the winding is DC or AC is related to its control mode, if the current flowing through the motor winding is DC using unipolar control, but the current flowing through the motor winding using bipolar control is AC.

What are the advantages and disadvantages of stepper motors?

Stepper motor compared to DC motor:

1. When the position is locked, the motor no longer consumes power

2. Small size and long life

3. Low cost and simple drive

4. The stepper motor can realize precise positioning control, which is widely used in displacement accurate positioning system; However, the control is relatively complex compared to DC motors

5. DC motor control is relatively simple, but the positioning accuracy is not high, and it can be used for systems with high speed requirements and low displacement positioning

6. The driving mode is different: the stepper motor moves in sections in a step mode. DC motors and brushless DC motors usually use a continuous moving control mode. DC motors require a feedback control system, which controls the motor position in an indirect way.

DC motor manufacturers

Most of the stepper motor system is operated in an “open loop” manner, and the stepper motor adopts a direct control mode, its main command and control variables are step position, and the DC motor is based on the motor voltage as the control variable, and the position or speed as the command variable.

What is the essential difference between stepper motor and brushless motor?

The essential difference between stepper motor and brushless motor is as follows:

1. Different composition: the stepper motor must be composed of a double ring pulse signal, power drive circuit, etc. to form a control system before it can be used; Brushless motors are not required.

2. The principle is different: the stepper motor is directly driven by a single pulse voltage; Brushless motors are controlled by alternating power supplies provided by Hall element positioning.

3. Different control accuracy: stepper motor is used in places with relatively high control accuracy requirements; Brushless motors are used where control accuracy is not required.

4. Different speeds: most of the general working speeds of stepper motors are below 500 rpm; Brushless motor can achieve high speed, 3000-8000r/min.