Analysis and solution of common fault causes of stepper motor drives. Stepper motor drive maintenance and testing process, how to check faults and questions, how to deal with the faults found, let’s know together.

Analysis and solution of common fault causes of stepper motor drives

Fault phenomenon: Once started, the external fuse of the driver of the stepper motor will be burned, and the device cannot operate.

Stepper motor drive maintenance and testing process, how to check faults and questions, how to deal with the faults found, let’s know together.

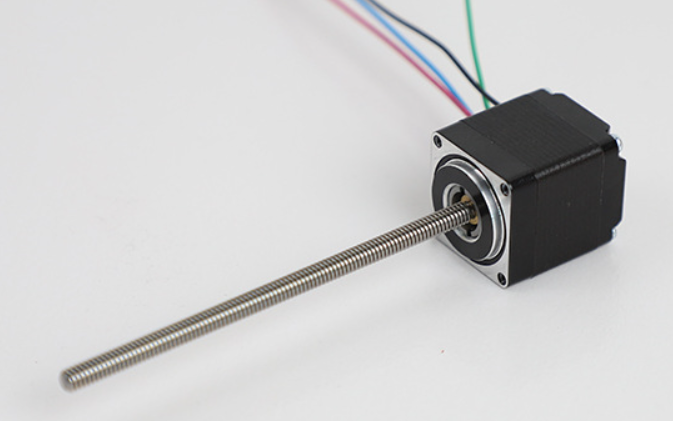

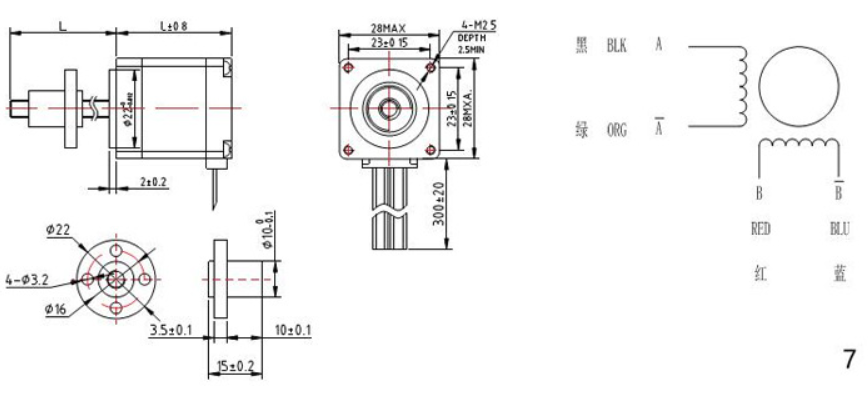

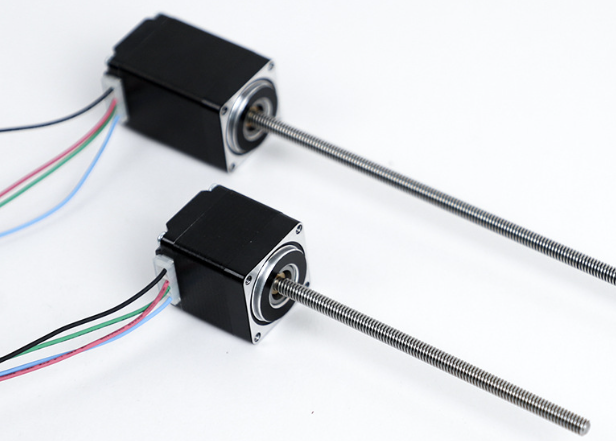

28 external drive type through-type screw stepper motor – Analysis and solution of common fault causes of stepper motor drives

Fault phenomenon: Once started, the external fuse of the driver of the stepper motor will be burned, and the device cannot operate.

Maintenance personnel in the inspection, found that a power tube has been damaged, but because there is no data, can not figure out the utility of the tube, think that it is the power drive of the front push, replace a power tube, after power-on, the insurance is burned again, replaced by the tube is also destroyed, by professional maintenance personnel inspection, the initial analysis is correct, that is, the insurance repeatedly fused, the driver recognizes the existence of an abnormal large current, and tested a power tube damage.

However, the utility of the tube has never been clarified, in essence, the tube is a stepper motor power drive tube, and the stepper motor is a high-voltage start, so it is burdened with a high-voltage and large current.

Static inspection shows that the resistance from the power supply to ground in the line of the pulse ring distributor is small, but it has never been short-circuited. According to the number of electronic components in the line and their power consumption, the resistance value of the power supply to ground should not be so small, so it is suspected that the electronic devices in the line have been destroyed.

Common faults of stepper motor drivers, common fault solutions of stepper motor drivers Power on test, find that a chip is abnormal fever, after power off, the power pin of the chip is cut off, static inspection, the resistance of the power supply to the ground should be normal, the resistance of the chip to the ground is very small.

Check the model of the chip, it is a non-standard model, which has never been found in many manuals. After line analysis, it was identified as the main component in the board: the ring pulse distributor.

In order to further identify the doubts of the chip, first replace the stepper motor power drive tube with the same withstand voltage current power, restore the power pin of the chip, and replace the windings of the stepper motor with a light-emitting diode circuit for the simulated load. After power-on, the light-emitting diodes are on, that is, all windings are energized, which does not meet the requirements of the line, and the input step pulse does not react, so it is determined that the chip has been damaged.

Solution: The chip has never been on the market, under the condition that the space in the stepper motor driver housing allows, the combination line is used to design a ring pulse generator with the existing D trigger and the combination of non-gate at hand, made on a small printed board, dismantle the original chip and install the small printed board on the pad of the original chip through the pins, still use light-emitting diodes as an analog load, and add human step pulses to light up in phase sequence after power-on. The simulated load is dismantled, connected to the host, powered on, and the device is operating normally.

28 external drive type through-type screw stepper motor features

Stepper motor operation is not running normally, the cause inspection measures

Introduction: Stepper motor operation questions, stepper motor abnormal operation fault handling methods, including motor heating, motor speed imbalance and even speeding cars, motor armature commutator formation of ring fire, motor speed is too slow, motor operation when secretly stopped and other faults of the solution.

2 phase 1.8 degree hybrid stepper motor

Stepper motor operation questions, stepper motor abnormal operation fault treatment methods, including motor heating, motor speed imbalance and even speed, motor armature rectifier formation of ring fire, motor speed is too slow, motor operation and other faults of the solution.

First, the cause of motor heating

1. The temperature of the motor commutator is too high, which is caused by the tight brush pressure, and the pressure spring should be adjusted to reduce the pressure.

2. The rectifier fairifier is insulated and convex, and should be stopped for grinding.

3. The commutation of the brush is not good, and the carbon brush should be adjusted to the diagonal direction of 180°.

4. The temperature of the motor ball bearing is too high, the ball bearing is damaged, and it should be replaced immediately. At the same time, due to the low lubricating oil of ball bearings, the ball bearing and the journal clearance are not well matched, which can also make the ball bearing temperature high.

5. The armature winding or excitation winding of DC motor has a local short circuit or open welding, the winding is damp, the motor will also have a fever, and the motor should be replaced or driven away in time. The reason why the stepper motor is not running normally, and the reason why the stepper motor is not running normally is checked.

Second, the motor speed is out of balance and even the speeding car

1. The thyristor BT151 on the speed control board of the operation motor is broken down, resulting in the speed being uncontrollable….

2. There is no excitation current, so that the motor runs under the condition of loss of magnetism, resulting in speeding. Therefore, it is not allowed to install a fuse in the DC motor excitation circuit, and the motor excitation circuit is not allowed to be disconnected and demagnetized.

3. An open circuit at the negative end of a given potentiometer DW is also easy to lead to a flying car.

Third, the motor armature commutator forms a ring fire

1. Mainly because the brush seriously deviates from the geometric center line, the air gap between the brush and the magnetic pole is uneven, and it should be adjusted again.

2. The contact resistance of the brush lead loop is large, resulting in uneven load distribution, and check whether the fastening bolt is loose.

3. The surface of the commutator and brush is unclean and is ground with glass fine sandpaper.

4. The texture of the brush is too soft, the size is not standardized, the wear is large, the pressure is uneven, and the brush should be replaced.

Fourth, the motor speed is too fast

Check the board given potentiometer DW and +3V given voltage, then check the thyristor BT151, which can be replaced with CR15 or CR20.

Check whether the voltage negative feedback adjustment potentiometer W2 is damaged.

Fifth, the motor speed is too slow

1. Check whether the voltage negative feedback potentiometer W2 adjustment is correct, appropriately reduce the negative feedback voltage, and increase the armature voltage of the motor.

2. Check whether the connection of the given potentiometer DW of the speed control plate is normal.

6. Secretly stop when the motor is running

When the motor is running, sudden stop, will grind the plate plywood, resulting in steel ball burns, affect the quality of the steel ball, and at the same time make the rotating plate channel damage, it takes a long time to press the plate groove again, which has a great impact on production, so pay special attention to maintenance when overhauling.

1. Measure whether the armature voltage is normal and whether there is fluctuation.

28 external drive through-screw stepper motor – high thrust stepper motor – lead screw stepper motor

Under normal circumstances, the voltage is adjustable from 0~220V, but considering the different speeds required for motor life and processing steel balls of different sizes, it is generally dominated by 0~160V.

2. If it meets the requirements, further check whether the carbon brush or commutator of the motor is normal, sometimes one side of the carbon brush can reach the commutator, while the other side cannot be touched.

Check whether the surface of the commutator is smooth, sometimes because the environment is humid or used for too long, carbides are formed on the surface of the commutator copper head, which leads to the pivot winding and does not get voltage and stops. The motor armature will also cause unstable speed because of the uneven surface of the copper head, and it can only be used after grinding with fine sandpaper.

3. If the armature voltage is unstable, focus on checking whether the output voltage of the LM3248 pin fluctuates, whether the power supply voltage +12V of the 4th pin is normal, and replace the piece if there is.