Advantages of linear screw stepper motors used on machine tools. Linear screw stepper motor is a mechanism that converts rotary motion into linear motion, which consists of a screw, a nut and a ball.

The advantages of linear screw stepper motors for machine tools are high precision, fast speed, simple mechanism and small size.

Tubular linear motor with 6w speed control brake small worm motor gearbox – height adjustable desk screw stepper motor – Advantages of linear screw stepper motors used on machine tools

Advantages of linear screw stepper motors used on machine tools

Due to the development of direct drive technology for linear screw stepper motors, the contrast between it and the traditional “rotary servo motor ball screw” drive method has attracted widespread attention in the motor industry. Now there are some technologically advanced machining center manufacturers that use it on high-speed machine tools. Because it has many advantages over the traditional way, we will now analyze it from three aspects;

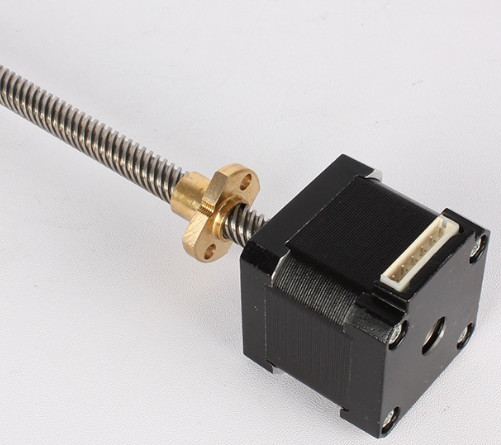

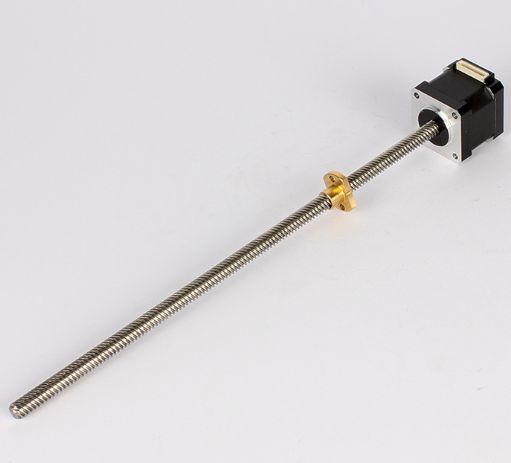

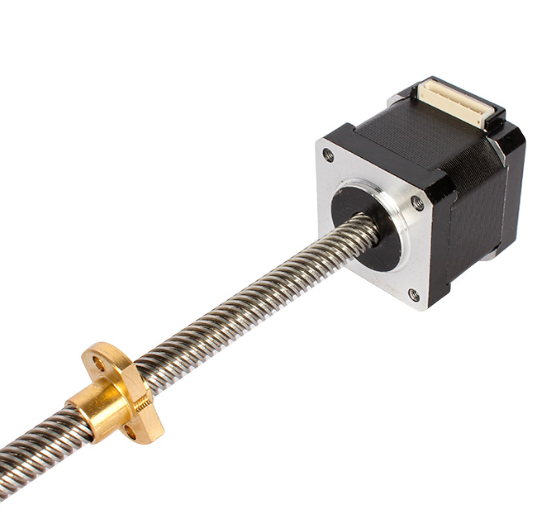

nema 14 screw stepper motor is used in 3D printers, stage lighting automation equipment manufacturers

Linear screw stepper motor

First, the accuracy aspect

Linear stepper motor because of the simple transmission mechanism, so reduce the problem of interpolation hysteresis, its positioning accuracy, reproduction accuracy, absolute accuracy, have through position detection and feedback control, and “rotary servo motor ball screw” is higher, and easy to achieve.

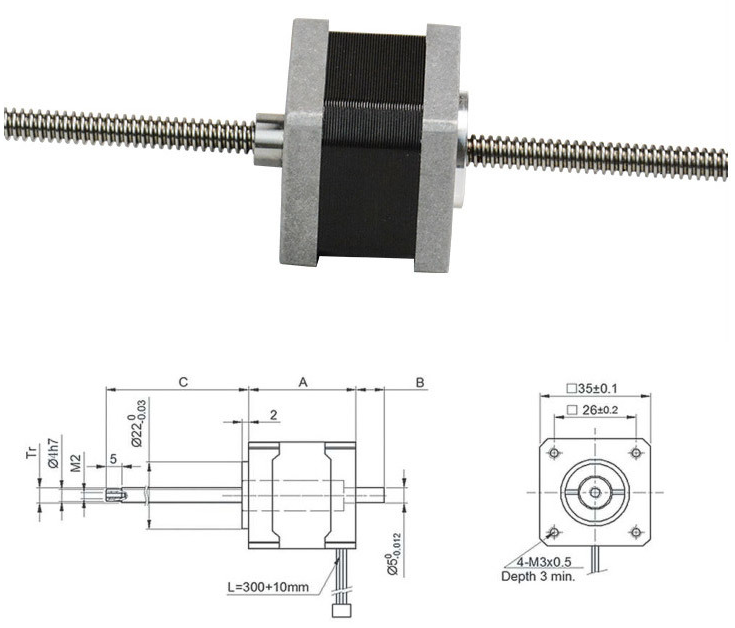

NEMA 14 NEMA 17 NEMA 23 Linear Screw Motor – Dimensional Diagram of Hybrid Two-Phase Stepper Motor for Linear Motor

The positioning accuracy of linear stepper motors can reach up to 0.1μm.” Rotary servo motor ball screw” can reach up to 2~5μm, and requires CNC-servo motor-backlashless coupling-thrust bearing-cooling system-high-precision rolling guide-nut seat-table closed-loop transmission part of the whole system, to be lightweight, and its grating accuracy is high.

NEMA 23 THROUGH-TRAPEZOIDAL SCREW STEPPER MOTOR SIZE BLOCK DIAGRAM – FUSELAGE 56MM LINEAR SCREW MOTOR MANUFACTURER

If you want the motor to achieve high stability, the “rotary servo motor ball screw” should adopt a dual-axis drive method, and the linear screw stepper motor is to take forced cooling measures for high-heating parts, which may be more costly than to achieve the same purpose.

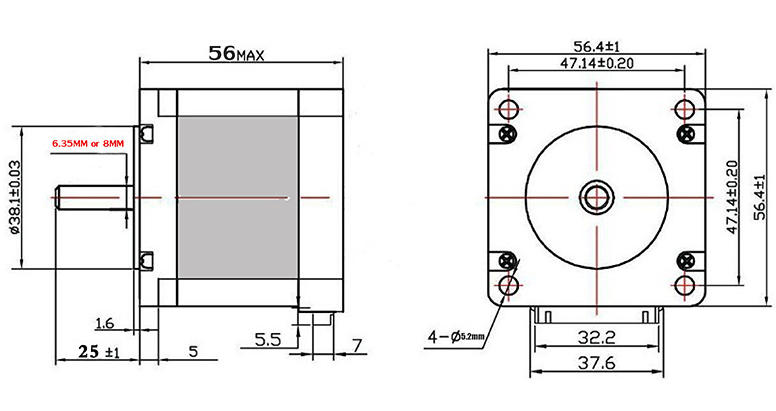

NEMA 14 NEMA 17 NEMA 23 linear screw motor, linear motor, hybrid two-phase stepper motor

Two. Speed-wise

Compared with the traditional rotary servo motor ball screw, the linear screw stepper motor has great advantages. The running speed of the linear stepper motor reaches 300m/min, and the acceleration can reach 10g; The ball screw runs at a speed of 120m/min and accelerates only 1.5g.

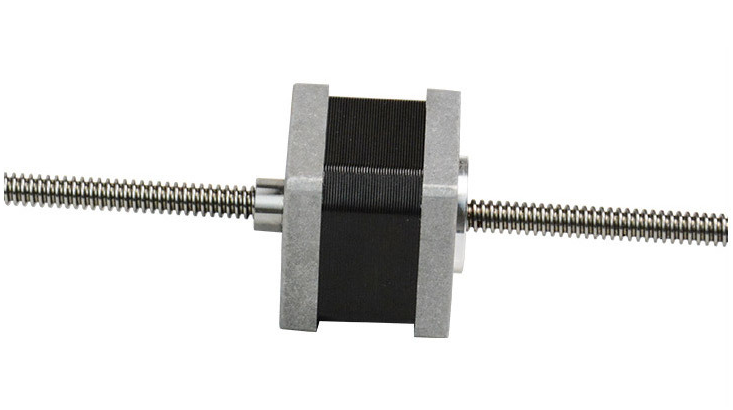

NEMA 23 through-ball screw stepper motor – reciprocating telescopic operation – stroke lead selectable

Just from the comparison between speed and acceleration, it can be seen that the linear screw stepper motor has great advantages, and after successfully solving the heating problem, the speed can be further improved, while the traditional “rotary servo motor ball screw” is limited in speed and is difficult to improve.

height adjustable desk screw stepper motor

Three. In terms of longevity;

Linear screw stepper motor because there is an installation gap between the moving parts and the fixed parts, but there is no contact, so it will not be worn due to the high-speed reciprocating motion of the mover, and the motion positioning accuracy is used for a long time, without much change, suitable for occasions that require high precision requirements.

DC Geared Motor – Screw Motor Manufacturer

The ball screw motor cannot ensure the accuracy of the motor in the high-speed reciprocating motion, and because of the high-speed friction, the lead screw nut will be worn, which will affect the accuracy requirements of the motor movement. It cannot be met for applications that require high accuracy.

Screw motor working principle diagram demonstration

To sum up, we can see from three aspects that linear screw stepper motors are stronger than traditional servo motors in terms of accuracy, speed and service life. Shenzhen Shenli Micro Motor Co., Ltd. is a specialized stepper motor manufacturer, producing linear screw stepper motor, deceleration stepper motor, brake stepper motor, stepper motor and other products.

NEMA 14 screw stepper motor

Linear screw stepper motor price:

The price of lead screw motors varies from country to country around the world, depending on the local situation or for the global market.

For example, a buyer in Russia wants to buy a screw stepper motor in China; Then a series of issues such as shipping costs will be taken into account; However, motorforum.rfidepc.com is a global stepper motor manufacturer and supplier, providing stepper, servo motor and other products to global users. WeChat or WhatsApp:+8618062443671

Two-phase hybrid NEMA 14 screw stepper motor

The characteristics of linear screw stepper motors for machine tools are:

1. High precision: positioning accuracy up to 0.1μm;

2. High speed: up to 300m/min;

3. Simple mechanism: reduce lag problems;

4. Small size: Compared with the way of converting the rotary stepper motor to linear motion through the motion mechanism, the mechanism is simple and the volume is reduced.