Is a stepper motor also flange mounted?

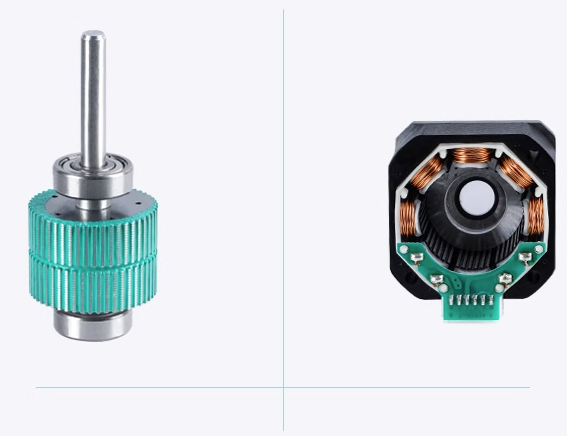

Stepper motors can also be flanged, depending on the specific application scenario and requirements.

Flange mounting refers to the connection between the motor and the load through a flange to achieve transmission and control. For some application scenarios that require high-precision position control, such as CNC machine tools, 3D printers, etc., flange installation is usually used to ensure the accuracy and stability of position control.

As a common position control motor, stepper motor can also be flanged mounted. For example, in some automation equipment, stepper motors can be connected to the drive shaft by flange mounting to achieve position control and motion control.

In short, the stepper motor can also be flanged installed, and the appropriate installation method needs to be selected according to the specific application scenarios and requirements.

Is a stepper motor also flange mounted?

If you need an integrated stepper servo that supports CANopen communication, you can contact us.

How is the flange motor mounted on the fixed plate?

The installation method of the ball screw is used

1. Temporarily lock the ball screw nut after inserting it into the nut support, temporarily fix the support unit on the fixed side and the support side to the base, move the workbench and the fixed side support unit, tighten and fix the support unit to the motor, move the workbench to the end of the stroke near the fixed side, and fix the workbench and the nut support to each other;

2. Fix the nut and nut support, loosen the bolt fixed by the fourth cloth, and fix the motor and nut support to each other again. Push the table to the fixed support unit to adjust its center position, so that the table can move smoothly;

3. After fixing, confirm the running status of the motor, that is, complete the operation.