The installation method of the ball screw is used

1. Temporarily lock the ball screw nut after inserting it into the nut support, temporarily fix the support unit on the fixed side and the support side to the base, move the workbench and the fixed side support unit, tighten and fix the support unit to the motor, move the workbench to the end of the stroke near the fixed side, and fix the workbench and the nut support to each other;

2. Fix the nut and nut support, loosen the bolt fixed by the fourth cloth, and fix the motor and nut support to each other again. Push the table to the fixed support unit to adjust its center position, so that the table can move smoothly;

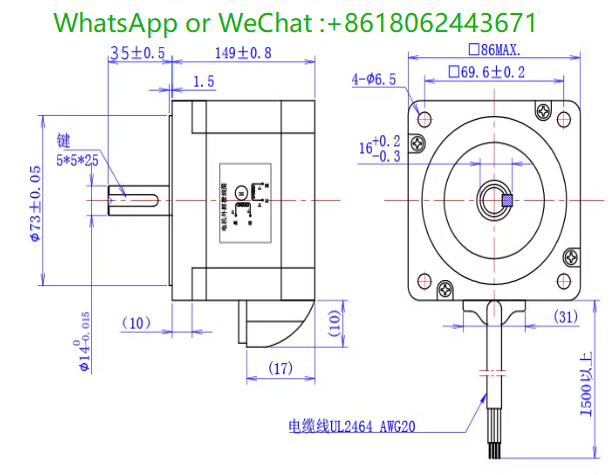

Stepper motor flange mounting dimension drawing

3. After fixing, confirm the running status of the motor, that is, complete the operation.