What are the applications of brushless drives in medical devices? Brushless drivers are widely used in medical devices, especially in scenarios where high accuracy, high reliability and low noise are required.

Here are some typical applications of brushless drives in medical devices:

What are the applications of brushless drives in medical devices?

1. Infusion pump and syringe pump: Brushless motor plays a key role in infusion pump and syringe pump. These devices require precise control of drug delivery speed and dosage. The high-precision control and stability of brushless motors help achieve this goal while reducing noise and providing a more comfortable treatment environment for patients.

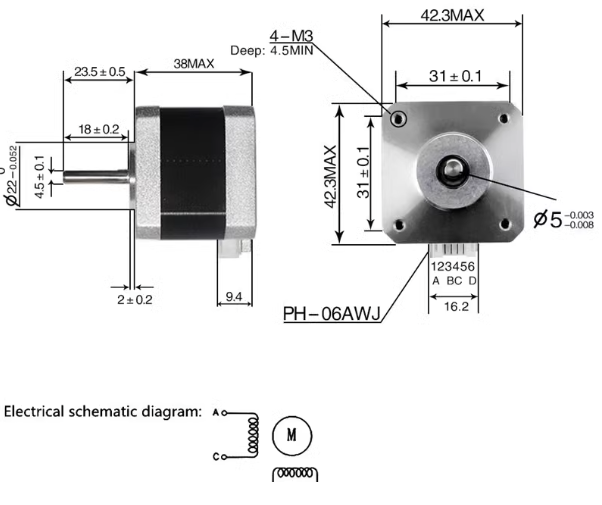

What are the applications of brushless drives in medical devices? 3D printer accessories nema 17 two-phase four-wire stepper motor wiring diagram and dimensions

2. Surgical robots: Surgical robots require high-precision and high-reliability drive systems. The high torque density and superior control performance of brushless motors make them ideal for these high-end medical devices. At the same time, the long life and low maintenance requirements of brushless motors reduce the overall cost.

3. Medical diagnostic equipment: brushless motors play an important role in medical diagnostic equipment, such as magnetic resonance (MRI), X-ray and ultrasound equipment. These devices require precise motion control and stable performance. The high precision and reliability of brushless motors help meet these demands.

PWM speed control plate with drive brushless motor

4. Centrifuges: Centrifuges in laboratory and clinical applications need to run at high speeds to achieve efficient separation. Brushless motors provide high rotational speeds and stable operation, ensuring reliable results when handling biological samples.

5. Ventilators and respiratory aid equipment: brushless motors are used in ventilators and respiratory aid equipment to achieve precise gas delivery and pressure control. In addition, low noise characteristics are important for patient comfort in a patient room environment.

6. Rehabilitation equipment: Rehabilitation equipment, such as exercise bikes, treadmills and strength training equipment, plays an important role in the process of physical therapy and rehabilitation. The high efficiency and reliability of brushless motors help provide a stable sports training environment for patients.

PWM speed control board with drive brushless motor – DC8-24V brushless DC motor governor

7. Biopharmaceutical equipment: In the biopharmaceutical process, it is necessary to precisely control the temperature, pressure and mixing processes. Brushless motors are widely used in these devices due to their precise control performance and high efficiency. In bioreactors, for example, brushless motors can precisely control the stirring speed to ensure homogeneous mixing of materials. In centrifuges, brushless motors provide high-speed and stable operation to achieve ideal separation. At the same time, the low noise performance of brushless motors helps to provide a better working environment.

DC brushless Hallless motor drive board DC12V-36V – 500W high power forward and reverse speed control controller

8. Mobile medical equipment: In wheelchairs, mobile beds and other mobile medical equipment, the high efficiency, lightness and reliability of brushless motors make it an ideal choice. Brushless motors provide powerful power and consume less battery, which is important for mobile medical devices that need to work for long hours.

PWM speed control board DC8-24V with drive brushless motor

In summary, brushless drives are widely used in medical devices and are important. They provide the advantages of high precision, high reliability, high efficiency and low noise, enabling medical devices to better serve patients and medical personnel.

Brushless driver selection: How to choose the right brushless driver?

When selecting the right brushless driver, several factors need to be considered to ensure that the motor meets the needs of your application. Here are some key factors to help you make more informed decisions:

1. Application requirements: First of all, clarify your application requirements, such as the required torque, speed, voltage and control accuracy. This helps narrow down your choices and find the brushless drive that fits your specific application scenario.

DC brushless Hallless motor drive board 500W high-power forward and reverse speed regulation controller DC12V-36V

2. Size and weight: According to the space limitation of your equipment, choose a brushless motor with the appropriate size and weight. Ensure that the motor can be installed correctly inside the device and is not too large or heavy, affecting the performance and portability of the device.

NEMA 23 high-torque open-loop two-phase stepper motor with DM542 stepper driver

3. Power and efficiency: choose a brushless motor with the required power output and high efficiency. High-efficiency motors provide better performance at lower energy consumption while reducing heat dissipation issues.

4. Torque and speed: choose the motor that suits your application needs and speed range. For example, some applications may require higher starting torques, while others may be more concerned with high-speed operation. Understanding your needs helps you find the motor that meets your requirements.

5. Control mode: according to your control needs, choose the appropriate control mode. Brushless motors are typically controlled by pulse width modulation (PWM), but in some applications you may need other types of control (e.g. position control, speed control, etc.). Make sure the selected motor supports the control you need.

nema 23 nema 34 stepper motor kit – 2-phase DM542 driver – DM860H 3-phase motor controller with brakes

6. Manufacturer and brand: choose brushless motors from well-known manufacturers and brands to ensure quality and reliability. Learn about the manufacturer’s after-sales support and warranty policies so that you can get timely solutions when problems arise.

7. Budget: Consider your budget constraints and choose brushless drives that achieve a balance between performance and cost. Note that motors that are too cheap may have quality issues and may require more repairs and replacements in the long run.

8. Environmental conditions: consider your application environment, such as temperature, humidity, pollution, etc. Choose a motor that works properly in these conditions and has the appropriate degree of protection.

By considering the above factors together, you can choose the brushless drive that suits the needs of your application. During the selection process, communicate your needs with the manufacturer or sales representative.