Robotics in practice – servo systems – Robot Motion Control. About the robot servo system. When we develop robots, one of the first problems we face is motor drives.

Robotics in practice – servo systems – Robot Motion Control

Drive technology has been relatively mature, and many companies have purchased drives for secondary development and use. If you develop a drive from the bottom, you need an experienced team, and the stability of the drive also needs to be run-in.

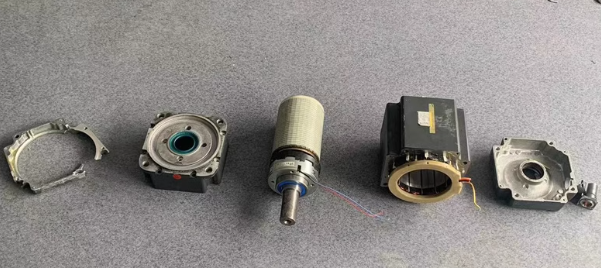

Manipulator servo motor joint module – servo robot – DC integrated servo – Robotics in practice – servo systems – Robot Motion Control

If the drive is purchased, the company can be equipped with a servo engineer and a robot motion algorithm engineer, taking robotic arm development as an example:

application of servo motor in robotics. Servo engineers mainly deal with joint system related issues. For example, the selection of joint servo system, system index testing, secondary development and production of motor drive applications, so it is more like a system engineer. Servo engineers should pay attention to the characteristics of variable structure and complex working conditions of the robot system, such as the configuration change of the robotic arm, the interaction between the flexible robotic arm and the human body, and the interaction between the quadruped robot and various grounds.

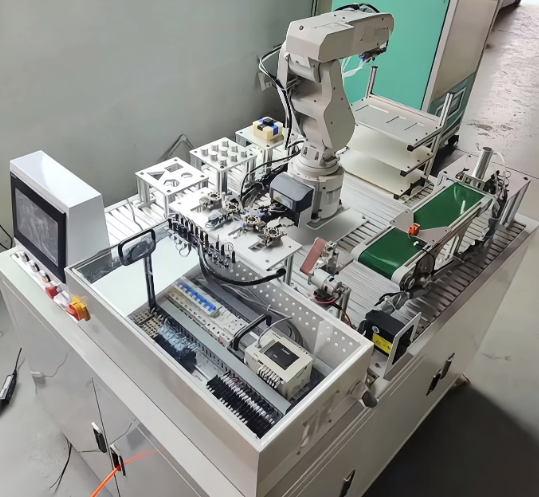

New industrial robot training teaching platform – six-axis robot – robotic arm teaching palletizing assembly vision

Robot motion control algorithm engineer. It mainly considers the problem from the robot system level, handles the kinematics and dynamic modeling of the robotic arm, cooperates with the camera, force sensor, etc. for motion planning, completes collision prevention, or involves flexible interaction functions in contact with the human body, and system vibration suppression. The two need to work closely together, and the work content is also very different.

Large industrial programmable robot palletizing handling, loading and unloading, two welding freedom manipulator

1. Joint system selection ( servos for robotics )

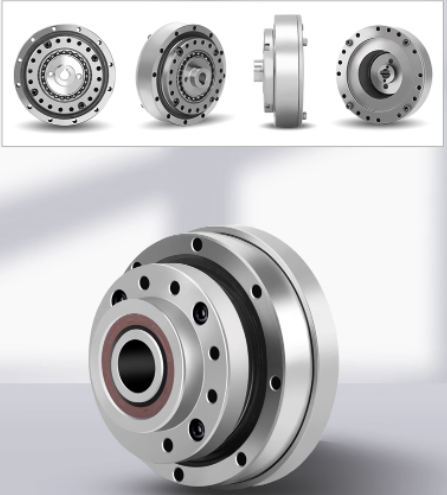

Choose direct drive, or motor + reducer.

For the location accuracy requirements are not so high, more emphasis on dynamic, interactive scenes, now direct drive is more and more popular, such as quadruped robots currently generally use direct drive, and even robotic arms have begun to explore direct drive. For the case of emphasizing position accuracy, a reduction ratio of 80 or 100 can improve the accuracy of the entire system, but the inertia introduced by the reducer increases sharply, the nonlinear link, friction increases, the dynamic performance decreases, and the difficulty of the algorithm to achieve variable damping and variable stiffness increases. The reduced ability to estimate joint torque by current requires the introduction of additional torque sensors.

Work curve

The working conditions of the general robot are more complicated, but it is necessary to preliminarily determine the working conditions of the system, the system start-stop, and the normal working curve (speed-torque curve). One of the most important indicators of the motor is its working curve. The working curve is the curve of torque (current) and speed, as shown in the figure below. Red indicates continuous operating interval, white indicates short-duration interval, and black line (marked with 40W) indicates the rated power line.

As can be seen from the figure, there is a white area below the rated power line (short-term work area), which is caused by the decrease in motor efficiency and increased heat generation. Therefore, the working area of the robot should match the curve of the motor as much as possible, of course, the robot joint also needs to consider the efficiency of the reducer and the working area.

DC servo motor controller system – robot joint module – servo drive encoder reducer set

System selection

The torque, power and speed of the motor are all considered. High-speed motors, low-speed motors, drive methods, and pole pairs may affect smoothness.

Taking the gimbal motor and the brushless motor of the drone as an example, one is a high-speed motor, the other is a low-speed motor, generally speaking, the number of pole pairs of the gimbal is more, its low speed is smoother, and the speed of operation is lower. The motor on the drone, which runs at a higher speed, may have a lower smoothness at low speeds.

Professional robot repair and maintenance – robot arm control cabinet teach pendant servo system repair

In the case of unchanged output power, the more pole pairs of the motor, the lower the speed of the motor, the greater the number of pole pairs on the torque of the ruler groove, the more pole pairs, the smaller the cogging effect (the motor is not energized, we rotate the motor by hand, there will be a feeling of a meal), the running is relatively smoother, and its torque is greater.

Manipulator servo motor – industrial robot joint module

2 – Indicator (servo motor applications pdf )

Power. For quadruped robots, its explosive power should be strong enough, the corresponding power should be sufficient, and the power-mass ratio should be larger, that is, the motor should be small. If the system is too bulky, the inertia will be greater.

Smoothness. The number of pole pairs of the motor and the drive mode (the sine wave is more stable than the square wave) will affect the smoothness. When the joint is installed, friction and clearance will be introduced, and if you make a robotic arm to connect with people, if the connection is loose and there is a gap, it will also affect the smoothness of output.

Large Industrial Programmable Robot Palletizing Handling Robot – High precision degree-of-freedom robotic arm

If the motor is assembled by itself, the installation of the motor leads to the imbalance of the magnetic gap, which will lead to unstable motor output, and this nonlinearity will be significantly amplified at a high speed, and it is difficult to solve from the algorithm side.

3- Test

Conventional drives are torque rings, speed rings, and position rings. It is a set of one loop, the current loop should be PI control, the speed loop should be PI control, and the position loop should be single P control. These three rings of PID are one ring and one ring. The current loop control frequency may reach 20 kHz, the speed loop may reach several kilohertz, and the position loop may reach several hundred Hz. The influence of the control frequency on the stability of the control system is very important, so it must be as high as possible, because if the system frequency is relatively low, this discreteness will reduce the smoothness of the entire system. MIT quadruped robot team, they have analyzed in one article.

robot arm control cabinet teach pendant servo system repair

First test the current loop control, the response of the motor will be related to his load, generally we lock the output of the motor, and then let it do a step of the moment to follow, through the step response, see the moment to follow the oscillation, in the case of the end lock, hope that the current follows the oscillation is larger, the system will respond faster, the system rigidity is better, but if the oscillation is too large, the system is easy to be unstable. You can also use a professional dynamometer. Therefore, adjust the current loop and then adjust the speed loop, and the speed adjustment loop needs to let the end rotate freely.

For speed control, the step response is smooth without overshoot, first look at the step response, how is the steady-state accuracy, you can increase the load to see the steady-state accuracy. In addition to the step response, you can try to sweep the frequency and plot the system Bird. Position control, taking single P control, can do point-to-point, as well as trajectory following experiments.

industrial robot joint or robotic arm

To grasp the step response of its system, we can also enter the working curve to test. However, the working curve test, which is more complex, may not be convenient to analyze, so it is difficult for us to make a comparison just through the working curve. Therefore, the step response and frequency sweep of the system is a relatively intuitive method, and then cooperate with the working curve. In the actual process, we should pay attention to the system sampling clock to be as accurate as possible.

High-precision servo motor – high-precision industrial robot joint module

Of course, in addition, there are durability tests, extreme working condition tests, electromagnetic radiation, electrostatic interference and other tests.

In the whole process, such as speed control, position control, current control, to consider the problem of load, generally to develop robots, will try to add the load as feed-forward, and then carry out a feedback control, anti-disturbance. Therefore, if the load is uncertain, it mainly relies on feedback control. Some errors are also introduced, and the magnitude of the error depends on the open-loop gain of the system after control, that is, the stiffness of the closed-loop control system.

Harmonic reducer, high precision servo motor, small reducer-industrial robot joint or robotic arm

If you want to take into account the robot and contact with people, take into account the rigidity and gap of the contact link. Previously, there was an experiment through a robotic arm, which touched the wall of a sponge, damping surface or a purely rigid spring, forming a stability of force interaction very differently.