Servo drive: domestic robot parts drive – Industrial robot joints

In recent years, the rapid recovery of China’s manufacturing industry has promoted the rapid growth of servo system and motion control products.

Integrated robot at work video demonstration

In 2022, the scale of China’s general servo system market increased by 35% year-on-year.

Since the industrial control industry requires higher product reliability than cost considerations, the localization rate is further improved.

Automatic spraying multi-joint manipulator – six-axis robot painting robot working process – Servo drive: domestic robot parts drive – Industrial robot joints

From the product side analysis, the localization rate speed (servo >PLC> inverter), and according to the project research progress of various industrial control enterprises, it is expected to usher in large-scale domestic replacement in the high-end field of industrial control in the next few years.

China R&D robot – fully automatic die casting spray picking integrated robot

In addition, some segments such as servo systems appear “involution”, after fierce cost reduction and price war, market concentration is expected to increase.

With the deepening of the industrial robot industry, the further improvement of industrial automation and the in-depth promotion of intelligent manufacturing, the servo system market is expected to show a new round of rapid growth.

Fully automatic die-casting spray pick-up integrated robotics

Servo system industry overview

The servo system takes the displacement, angle and speed of the object as the control quantity, and can track the automatic control system of any change of the target.

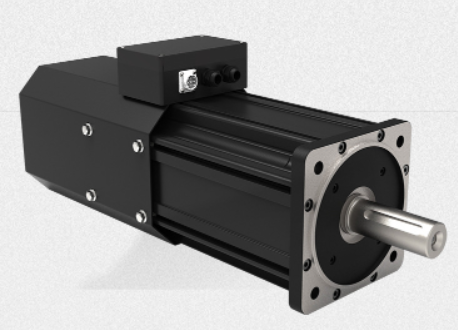

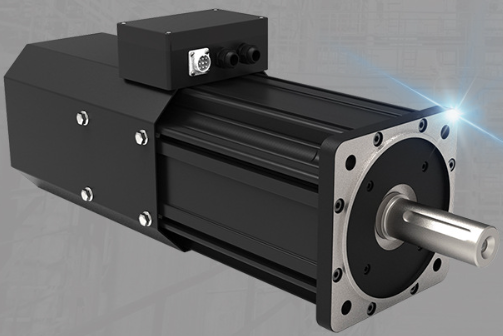

Structurally, the servo system usually includes three parts: servo drive (command device), servo motor, and servo feedback device (encoder). Usually the encoder is embedded in the servo motor, and the way to obtain the encoder varies from manufacturer to manufacturer.

After the controller gives the command, the drive is converted into a current capable of driving the motor to rotate. In the traditional motion control system, the control and drive plates are separated, and the space for improving the accuracy of motion control is limited.

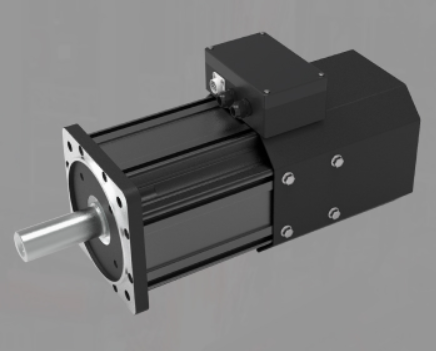

permanent magnet servo motor – servo drive motor

The servo system is mainly composed of servo drive, servo motor and encoder:

The servo performance represents the overall technical level of the system, and any short board will produce a barrel effect. In addition, servo is not an isolated system, its application must be combined with PLC, motion controller and other upper control systems and reducers and other lower transmission structure, many manufacturers will drive the position ring and speed ring in the upper control system, and supplemented by interpolation and multi-axis control and other technologies, to achieve more complex motion control, the future servo product competitiveness is also reflected in the comprehensive automation product solution ability.

Robot joint drives can be divided into hydraulic, pneumatic, electric drive, etc. according to the power source.

permanent magnet servo motor working principle

Although the hydraulic pressure has high power, it has low reliability and precision, high noise and high cost; Good aerodynamic compliance and high safety, but poor precision and high time lag.

Electric drives have gradually become mainstream due to their advantages in precision, quietness and efficiency, and after more than 30 years of development, they have gone through the process from rigid drives, elastic drives to collimated drives.

Tesla in the United States adopts the earliest and relatively mature rigid drive scheme. If the performance of the motor and reducer is not greatly improved, rigid drives will be gradually replaced in the field of bipedal robots. In recent years, emerging collimating drive technology has developed rapidly, and it is expected to replace traditional rigid drives in the future.

Servo drives used at the joints of humanoid robots: high-torque servo drives and small and medium-torque servo drives.

The servo drive is the core link of the motion control system, and is the brain and center of the servo system.

Its three rings from the outside to the inside are the position loop, speed loop and current loop, the innermost loop of the current loop response speed requirements are the highest, the three rings in the speed loop and the current loop is the standard to measure the driving performance index, the frequency response of the current loop is generally a fixed multiple of the speed loop (more than 4 times), so the industry generally takes the frequency response of the speed loop as a performance index.

China permanent magnet servo motor manufacturer

The development of servo drives, motion algorithms and AI technology has provided the possibility for the maturity of humanoid robot technology.

The short board of China’s servo drive system is mainly that power modules, main chips, encoders and other hardware need to be imported.

However, through the improvement and iteration of key software algorithms, the adaptability of motors and drives has been improved, and more than 80% of the application scenario needs have been met, and the price and service are closer to the needs of the Chinese market, and the market share of Chinese domestic brands is increasing.

Among the drive modules, IGBTs are the most important and cost-oriented components.

Foreign brands in the global IGBT market share of more than 20%, second only to Infineon, other foreign brands and domestic manufacturers from dealers to purchase IGBT, the current largest supplier of domestic servo enterprises is Infineon, procurement costs depend on the scale, and IGBT demand customers in the industry supply tight supply stability is higher.

Servo drive requires high integration, high power density and high overload capacity, and silicon carbide performs much better than IGBT in servo drive because of its higher switching frequency and lower loss. In recent years, various industrial control manufacturers are also successively deploying silicon carbide drivers.

Servo system market landscape

From the perspective of the servo system market structure, foreign brands occupy a higher market share, due to technical barriers, the market concentration of the top ten enterprises has reached 72%.

China automatic spraying multi-joint manipulator processing arm length 2050-10 six-axis robot painting manipulator

Among them, Japanese brands entered the Chinese market earlier, with Panasonic, Yaskawa Electric and Mitsubishi Electric accounting for 8.0%/7.7%/7.5% market share respectively in 2022; European and American brands Siemens (10.5%), Omron (2.3%) and Schneider (1.3%) together account for about 14.1% of the market share.

After years of technology accumulation, the market share of local brands continues to expand, Huichuan Technology ranks first among domestic brands with a market share of 21.5%, and the share of Hechuan Technology (3.4%), Xinjie Electric (2.6%), Eston (2.7%) and so on has gradually increased.

The servo drive system for industrial robots has a history of more than 50 years, especially with the development of power electronics technology, motor permanent magnet material technology and control bus technology in recent years, servo drives have been greatly improved in terms of processing speed, response speed, control accuracy and other aspects.

European and American brand servo drives are characterized by strong overload capacity, good dynamic performance, excellent bus technology performance, and good development, typical representatives are Siemens, Beckhoff, B&R, Rockwell, etc.; Japanese brands are characterized by affordable price, small size, light weight, and slightly weaker dynamic performance, which can meet most application requirements, typical representatives are Yasukawa, Panasonic, Mitsubishi, etc.; In the high-end industrial robot application industry, foreign brands of servo drives occupy more than 80% of the domestic industrial robot servo drive market share.

China manufacturer servo motor 200STB7.5KW-22KW 3000rpm high power permanent magnet motor

Domestic industrial robot servo drives started late, but developed rapidly, and there are more than 30 large-scale servo manufacturers, mainly represented by Huichuan Technology, Eston, INVT, Xinjie Electric, Guangzhou CNC, Meixin and so on. Some manufacturers in the subdivision of the industrial chain also include Lechuang Technology, Baichu Electronics, Weihong Co., Ltd., Golden Orange, Leisai Intelligence, Gootech and so on.

The domestic servo drive system is not much different from foreign servo drives in terms of function, and there is still room for improvement in performance. In the fields of welding, spraying, heavy handling and other applications of industrial robots, the dynamic response, adaptive ability and overload capacity of domestic servo systems still need to be improved.