The five most commonly used industrial robots in manufacturing factories, high employment costs, low efficiency, more and more factories are considering replacing people with machines, today I will reveal to you which industrial robots are used in which places.

We are robot servo motor supplier, welcome to consult us to select servo motor products, email: anwenqq2690502116@gmail.com

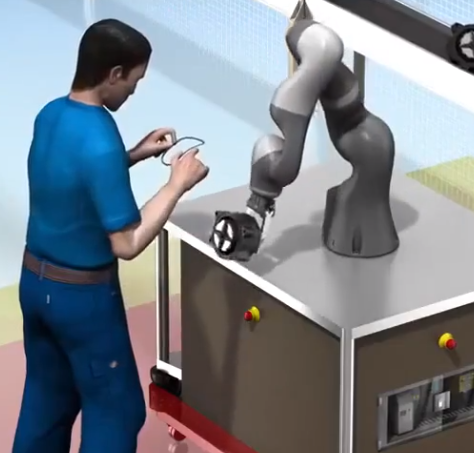

First, multi-joint robots, the most common is a six-axis robot, he is like one of our arms, high flexibility, can carry out high-speed actions, and occupies a small space, common application scenarios are handling, palletizing, welding, spraying, grinding, packaging.

vr robot programming

Second, the plane multi-joint robot, also called SCARA, also known as a four-axis robot, the cost is less than half of the six-axis robot, generally used for a plane handling, assembly, dispensing, screw locking and other work.

Third, parallel robotic arm, he is characterized by fast speed, the highest grasp speed can reach 120 times per minute, but the accuracy is slightly bottom, through the vision system, identify the type and location of the item, coordinate information to grab, commonly used food daily chemical industry classification and packing work.

Fourth, Cartesian coordinate robot design flexibility, low cost, high precision characteristics, at the same time control is simple and convenient, soldering machine, dispensing machine, automatic locking screw machine and non-standard equipment is very common.

VR Robotic automation

Fifth, The AGV trolley can travel along the prescribed guidance path. With safety protection and a variety of transfer functions of the transport vehicle high degree of automation, can realize the automatic transfer of materials, when the power is exhausted and will automatically return to charge, improve the efficiency of logistics warehousing and transportation, at the same time construction, simple results will be often used in automated production line supply workshop material transfer in and out of the warehouse, containers and other logistics industry automatic handling.