The rotation of one joint in the arm of a multi-joint robot at an angle will cause the other joints and their connecting rods to generate a movement in space.

Five-and-six-axis-articulated-robots

Correspondingly, the claw reaches a new position and the direction (posture) it is in also changed. Therefore, general articulated robots need to be controlled by computers.

The robot is equipped with angle detectors on each joint. The problem of knowing the rotation angle of each joint and requiring the spatial position and posture of the claw is called the analysis problem of motion control.

Conversely, knowing the position and posture of the claw, the problem of how many angles each joint link should rotate is called the comprehensive problem of movement. The key to these problems is how to use computers to perform the above transformations and calculations.

Classification according to the structure of articulated robots:

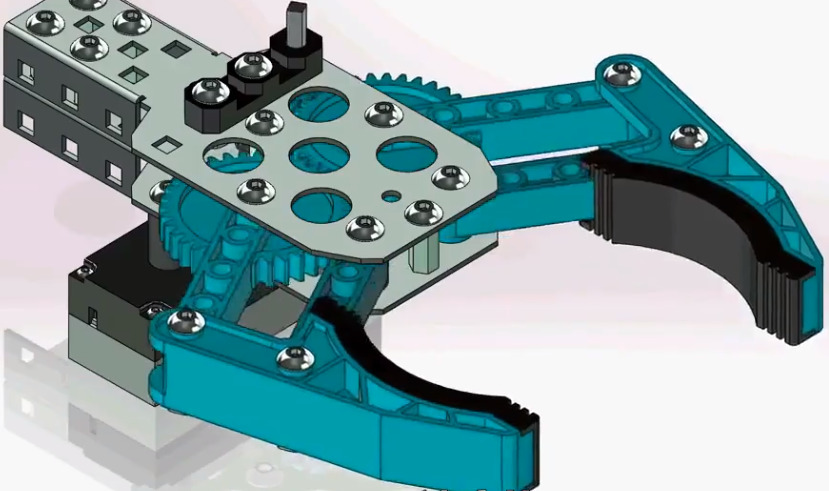

1. Five-axis and six-axis articulated robots

Has five or six axes of rotation, similar to a human arm.

Application areas include loading, unloading, painting, surface treatment, testing, measurement, arc welding, spot welding, packaging, assembly, chip machine tools, fixation, special assembly operations, forging, casting, etc.

2. Pallet joint robot

Two or four rotary axes and positioning locking for the mechanical gripper.

Application areas include loading, unloading, packaging, special handling operations, pallet transportation, etc.

3. Flat joint robot SCARA

Three axes of rotation parallel to each other and one linear axis.

Application areas include loading, unloading, welding, packaging, fixation, coating, painting, bonding, packaging, special handling operations, assembly, etc.

In addition, it can also be classified according to the working nature of joint robots, which can be divided into many types, such as: handling robots, spot welding robots, arc welding robots, painting robots, laser cutting robots and so on.