What are the subsystems of industrial robots? What are the roles of each?

Drive system: the transmission device that makes the robot run.

industrial robot manufacturers in india

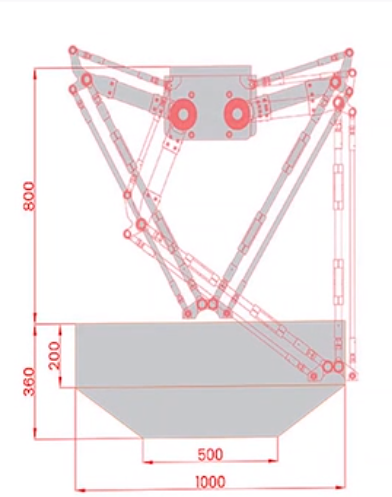

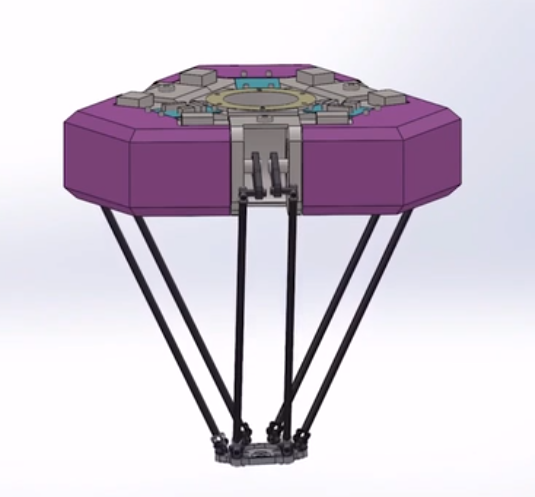

Mechanical structure system: a multi-degree of freedom mechanical system composed of three parts: fuselage, arm, and manipulator end tools.

Sensory system: composed of internal sensor module and external sensor module to obtain information on the state of the internal and external environment.

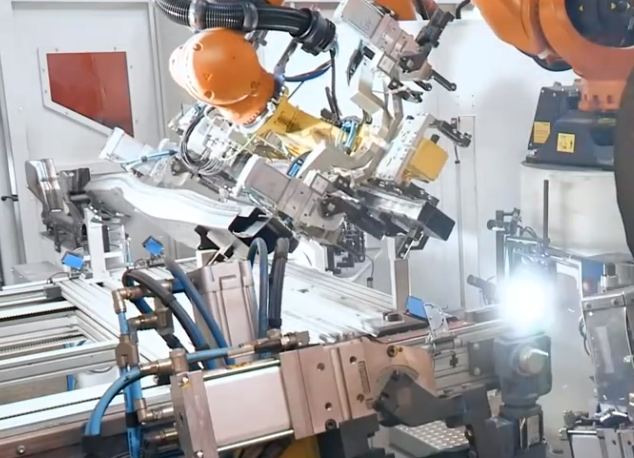

Robot & environment interaction system: a system that realizes the interconnection and coordination of industrial robots and equipment in the external environment.

robots stepper motor

Human-computer interaction system: It is a device for operators to participate in robot control and contact with robots.

Control system: According to the robot's operation instruction program and the signal feedback from the sensor, the robot's actuator is controlled to complete the specified movement and function.

What is the freedom of robots?

What is the definition of an industrial robot?

How many degrees of freedom do I need for robot position operation? How many degrees of freedom do I need for attitude operation?

The degree of freedom refers to the number of independent coordinate axis movements that the robot has, and should not include the opening and closing degrees of freedom of the claw (end tool), which requires six degrees of freedom to describe the position and attitude of an object in three-dimensional space, 3 degrees of freedom (waist, shoulder, elbow) for position operation, and 3 degrees of freedom (pitch, yaw, roll) for attitude operation.

The degrees of freedom of industrial robots are designed according to their use and may be less than 6 degrees of freedom or greater than 6 degrees of freedom.

What are the main technical parameters of industrial robots?

Degrees of freedom, repeatable positioning accuracy, operating range, maximum operating speed and load capacity.

What are the roles of the fuselage and arms? What issues should I pay attention to when designing?

The fuselage is a component that supports the arm, generally realizing movements such as lifting and swinging and pitching, and the fuselage design should have sufficient rigidity and stability; The movement should be flexible, the length of the guide sleeve of the lifting motion should not be too short, to avoid the phenomenon of seizure, generally there should be a guide device; The structural arrangement should be reasonable, the arm is a component that supports the static load of the wrist, hand and workpiece, especially when moving at high speed, it will generate a large inertial force, cause impact, and affect the accuracy of positioning.

When designing the arm, pay attention to high rigidity requirements, good guidance, light weight, stable movement, and high positioning accuracy.

Other transmission systems should be as short as possible to improve transmission accuracy and efficiency; The arrangement of each component should be reasonable, and the operation and maintenance should be convenient; Special circumstances, special considerations, the influence of thermal radiation should be considered in high temperature environments, and corrosion prevention should be considered in corrosive environments. Hazardous environments should consider vandal protection.

What is the main role of freedom on the wrist? If the hand is required to be in any direction of space, what degree of freedom should the wrist have?

The degree of freedom on the wrist is mainly to achieve the desired posture of the hand.

In order to make the hand in any direction of space, the wrist is required to be able to rotate the three axes of space, X Y Z. That is, it has three degrees of freedom of flip, pitch and deflection.