Introduction to the application scenarios of industrial robots in the field of processing and manufacturing

industrial robot manufacturers in india

With the continuous improvement of automation and intelligence in the manufacturing industry, industrial robots have developed rapidly, and the application of industrial robots in the field of processing and manufacturing is becoming more and more mature.

The "Industrial Internet" of the United States, the "Industry 4.0" of Germany, and the "Made in China 2025" of China are all promoting manufacturing enterprises to apply industrial Internet of Things, AR, cloud computing and other technologies to realize automated, informatized and intelligent smart factories.

Among them, AGV handling robots, stamping robots, palletizing robots and other industrial robots have become the main force of smart factories, which have been widely used in the manufacturing industry.

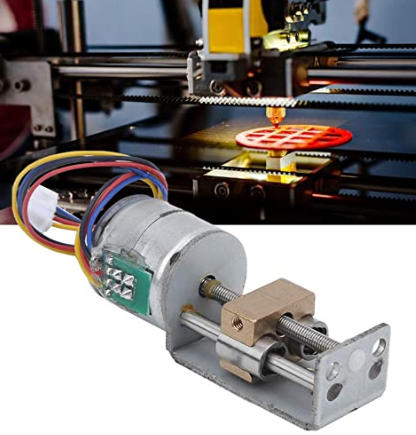

NEMA 8 20 Mini Stepper Motor with Linear Lead Screw Nut Slider 2‑Phase 4‑Wire Slider Stroke 22mm

AGV handling robot

AGV robots have a high degree of automation, and replacing manual handling can greatly improve handling efficiency and liberate porters from monotonous and repetitive high-intensity work. AGV handling robot realizes unmanned operation in the storage area, and the automatic handling of goods, semi-finished products and raw materials in the production process can meet the application requirements of different environments.

Stamping robots

Stamping robots are widely used in machinery manufacturing, metallurgy, electronics, light industry and atomic energy and other enterprises, the main reason is that these industries in the production process of repetitive actions are relatively more, the value of the application of stamping robots will be very high, the use of stamping robots to produce goods will be very efficient, thus bringing higher profits to enterprises.

The robotic arm automatically takes out the produced products and places them on the conveyor belt or undertaking table to upload them to the designated target location, so that one person can see two or more injection molding machines at the same time, which can save manpower and material resources and reduce the cost of enterprises in the production process.

Palletizing robots

Palletizing robot is the packaging of goods neat, automatic palletizing, in the end effector installed with mechanical interface, can be followed by the gripper, so that palletizing robot application in more occasions, its application in industrial production and three-dimensional warehouse, the use of palletizing robot will undoubtedly greatly improve the factory strength, reduce the work intensity of workers, in individual harsh working environment but also to the personal safety of workers to play an effective role.

Robotic sorting

Robot high-speed sorting can accurately track the speed of the conveyor belt in the rapid assembly line operation, identify the location, color, shape, size, etc. of the object through visual intelligence, and pack, sort, arrange and other work according to specific requirements, with its fast and flexible characteristics greatly improve the efficiency of the enterprise production line and reduce the operating costs of the enterprise.

Robotic laser cutting

Laser cutting using the flexible and fast working performance of industrial robots, according to the size of the customer's cutting and processing workpiece, you can choose robot formal or flip installation, teach programming or offline programming for different products, and the sixth axis of the robot is loaded with fiber laser cutting head for three-dimensional cutting of irregular workpieces. The processing cost is low, and although the equipment is more expensive at one time, the continuous, large number of processing ultimately reduces the comprehensive cost of each workpiece.

Robotic welding

The use of robots for welding operations can greatly improve production efficiency and economic efficiency; The parameters of welding play a decisive role in the welding result, and the speed, dry elongation, etc. are changed during manual welding. The movement speed of the robot is fast, up to 3m/s, or even faster, the use of robot welding efficiency can be increased by 2~4 times than the same manual welding, and the welding quality is excellent and stable.

Painting robot

The spraying robot sprays precisely according to the trajectory, without offset and perfectly controls the start of the spray gun. Ensure that the specified spray thickness is kept to a minimum. Spraying robot spraying can reduce the waste of spraying and spraying, extend the filtration life, reduce the plaster content of the spray booth, significantly extend the working time of the filter, and reduce the scale of the spray booth. 30% higher conveying levels!

Robot vision applications

Robot vision technology is to add machine vision to the industrial robot application system, and coordinate with each other to complete the corresponding work.

The use of industrial robot vision technology can avoid the influence of some external factors on the inspection accuracy, effectively overcome the influence of temperature and speed, and improve the accuracy of the inspection. Machine vision can detect the shape, color, size, brightness, length, etc. of the product, and with industrial robots, it can complete the positioning, tracking, sorting, assembly and other needs of materials.