What are the challenges to keep in mind when replacing stepper motors with servo motors?

In making a design plan must use servo motor how not easy to measure the model specifications that should be used, there are long-selected stepper motor model specifications on the Internet, to find out whether it is possible to use the same specifications as the stepper motor servo motor.

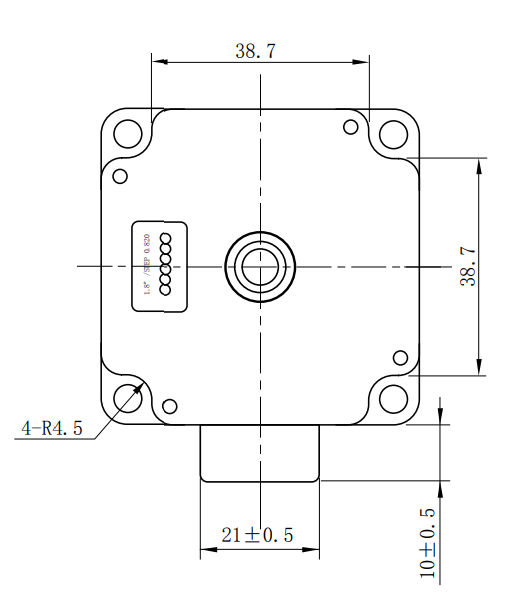

nema 23 stepper motor specifications

There is no problem at all, the control of the first servo motor is more accurate due to the servo motor and feedback mechanism, the cost has increased a little, and the stepper motor has no feedback, but the output power of the two is the same, in addition to the general design scheme has a certain capacity.

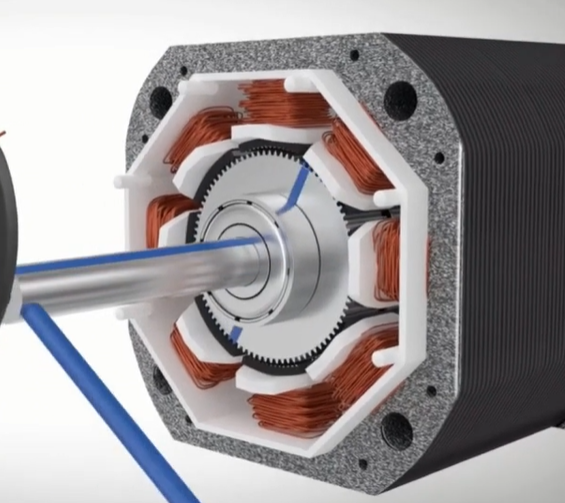

3D printed stepper motor internal mechanism diagram

In the actual application place, when the terminal equipment load is stable, the posture is simple, and the foundation is running at low speed, it is more suitable to use a low-cost and very easy to control stepper motor; However, when the load fluctuation range of the terminal equipment is large, the posture is simple, and the foundation is running at a low speed, if the stepper motor is selected, it will encounter a series of troubles, because the stepper motor selected by the waveform driver cannot remove the vibration and noise, and will cause step loss or overshoot due to torque fluctuation.

In fact, when the load fluctuation range of terminal equipment is very large, even if the basis is low-speed operation, servo motors should be used, because after considering the role improvement factors, environmental protection and energy-saving factors, control precision improvement factors, system software reliability improvement and other factors, it will be found that the use of higher price servo motors increases the comprehensive cost.