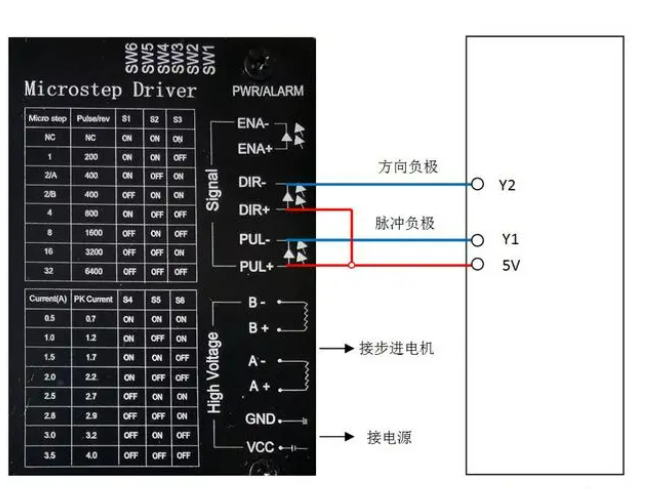

This is a schematic diagram of the structure that controls multiple stepper motors

Selection of controller model

Select the controller type and model from the following aspects:

1. Whether it can control multiple stepper motors;

2. Whether it can be mixed and controlled;

3. Whether it is suitable for use in control system occasions;

4. Is it easy and practical to use;

5. Whether you can master the programming technology of the control.

Select the meter-controlled controller, and check one by one as follows:

1. The meter control has 4 pulse output terminals, which can control up to 4 stepper motors or servo motors. There will be more pulse output terminals in the future. Currently, it can control 4 stepper motors to meet the requirements;

2. It can control various loads such as cylinder, hydraulic pressure, stepping motor, servo motor, etc. at the same time, and can realize the requirements of mixed control of various loads;

3. Considering that it only controls 4 stepping motors, the meter control can also control other loads with mixed control, and the anti-interference ability is also very strong. It is suitable for use in occasions with severe interference, and is used for control systems such as electric welding machines with severe interference. Work is also very stable.

4. Use table settings instead of programming, and use the mouse to set settings on the table according to the actual function requirements, which is relatively easy to use.

5. Whether you can master the use of meter control technology and programming technology is more important. The method of form setting is easier to master than programming, and form setting is simpler, more intuitive and easier to understand than traditional programming.