1. The motor has a common formula, P=MN/9550

P is the rated power, M is the rated torque, N is the rated speed, so please confirm the motor power and rated speed to obtain the rated torque size. Note that the unit of P is KW, the unit of N is R/MIN (RPM), and the unit of M is NM.

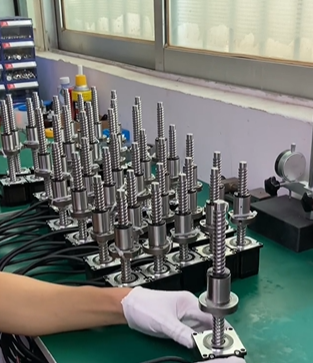

Screw closed loop stepper motor

2. Torque and torque are completely a concept, which is the product of force and force arm length, in NM (Newton meters);

For example, a motor output torque of 10nm, at a distance of 1m from the output shaft (force arm length 1m), a force of 10n can be obtained; if it is 10m away from the output shaft (force arm length 10m), only 1n of force can be obtained.

Motor torque selection

Moment of inertia calculation

In rotational motion, the moment of inertia J of an object corresponds to the mass of the object in linear motion. To calculate the dynamic load of the system during acceleration, it is necessary to calculate the moment of inertia J and angular acceleration w of the object, and then derive the moment of inertia T = J*w.

The moment of inertia of an object is: J=∫r²pdV, where dV is the volume element, p is the density of the object, and r is the distance between the volume element and the rotating axis. Unit: Kgm². Take a cylinder as an example:

J=W/8(D/10³)²=πp/32(L/10³)(D/10³)^4, where: L(length/mm)D(diameter/mm)

To convert the load mass to the moment of inertia on the output shaft of the motor, the common transmission mechanism and formula are as follows:

1) Ball screw

J=W(1/2π*BP/10³)²*GL²

W: Total mass of movable part (Kg)

BP: Lead screw pitch (mm)

GL: Reduction ratio

2) Rack and pinion, conveyor belt, chain transmission

J=W(1/2*D/10³)²*GL²

W: Total mass of movable part (Kg)

D: Pinion diameter (mm)

Sprocket diameter(mm)

GL: Reduction ratio

3) Rotating body, turntable drive

J=(J1+W(L/10³)²)*GL²

J1: The moment of inertia of the turntable

W: The mass of the object on the turntable (Kg)

L: Distance from the object to the axis of rotation (mm)

GL: Reduction ratio

4. Acceleration calculation

For the control system to be accurately positioned, the object movement must have an acceleration and deceleration process.

Given the acceleration time △t and maximum speed Vmax, it is easy to calculate the angular acceleration of the motor: w=Vmax/△t(rad/s²)

5. Motor torque calculation

T=(J*w+TL)/n, where: TL is the torque converted from the external force of the system to the motor; n is the efficiency of the drivetrain.

According to the calculated torque T plus a certain safety factor, the model of the motor can be selected.