China rare earth permanent magnet materials industry – robots and rare earth permanent magnet motors. Gallium, germanium related resources to implement export control! Rare earths have also been valued by the market, and concept stocks are pulling wildly.

Rare earth permanent magnets! New investment opportunities under the wave of robots are expected to drive new demand for rare earth permanent magnets.

What is the rare earth permanent magnet industry?

The rare earth permanent magnet industry refers to the industry that uses permanent magnet materials made of rare earth elements for production.

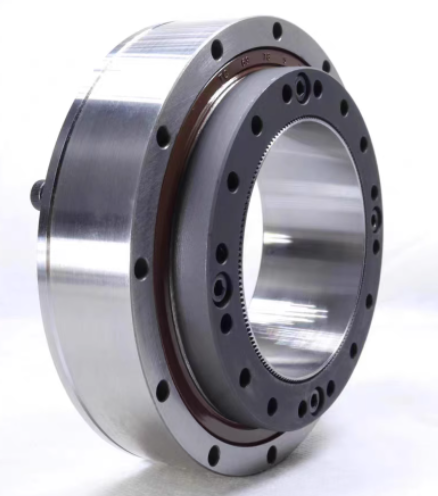

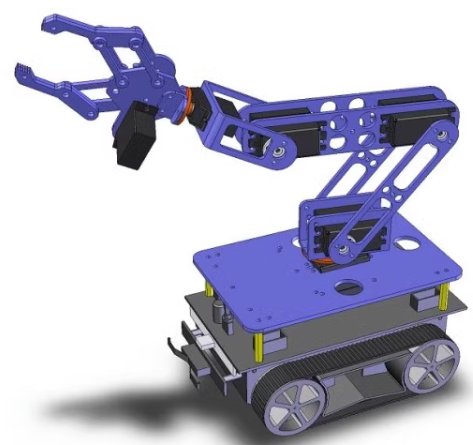

Harmonic reducer industrial collaborative humanoid robot – robotic arm joint transmission cup type high-precision automation

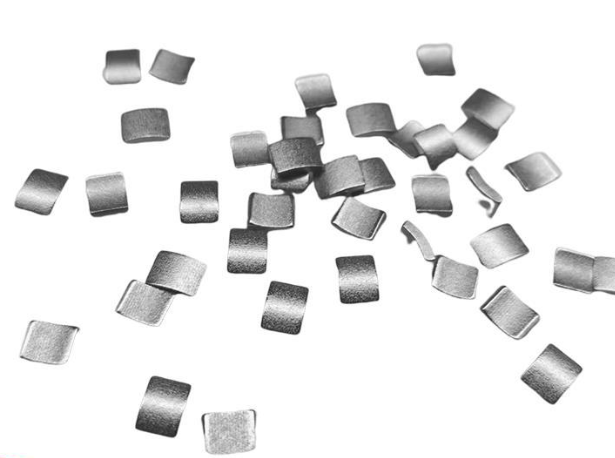

Rare earth permanent magnet materials are mainly divided into two categories, one is samarium-cobalt permanent magnet materials, and the other is NdFeB permanent magnet materials. The main components of samarium-cobalt-based permanent magnet materials are samarium and cobalt, which have high magnetic properties and stable magnetism, but are expensive.

Rare earth permanent magnet materials are widely used, including consumer electronics, automobiles, wind power, robotics and intelligent manufacturing.

Robot joint module

At present, China is the world’s largest producer of rare earth permanent magnet materials, and other major producers include Japan, the United States, South Korea and so on.

Are rare earth permanent magnet materials related to robots?

Relate. Rare earth permanent magnet materials can be used in actuators and sensors of robots, such as electromagnets and electromagnetic sensors. Therefore, rare earth permanent magnet materials have a wide range of applications in the field of robotics.

In 2023, the integration of the rare earth industry chain will continue to advance, and the industrial structure is expected to accelerate and optimize;

Pay attention to the rare earth magnetics investment opportunities brought by the robot sector, and high-quality stocks may welcome a good opportunity.

Rare earth permanent magnet materials – environmental protection and safety materials – rare earth permanent magnet steel

In early trading on July 5, the rare earth plate fluctuated and rose. As of press time, Zhongke Magnetics 20CM up limit, Earth Bear, Galaxy Magnet rose by more than 10%, China rare earth, Jinli permanent magnet and many other stocks have followed.

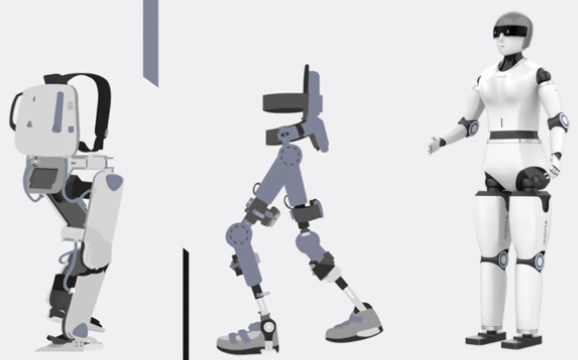

1. Humanoid robots accelerate commercialization, rare earth permanent magnets welcome the new wind

Some time ago, the robot concept was on fire, and the reducer in the plate ushered in a wave of climax.

Today, let’s take a look at an important link: servo motors. China Post Securities said in the research report that servo motors are the core components of robots, and the cost of permanent magnets such as NdFeB accounts for about 45%. Referring to the cost proportion of industrial robots, the proportion of core components is close to 70%, of which reducers, servo motors and controllers account for 35%, 20% and 15% respectively. Among them, servo motors are often used in robot joints, mainly divided into AC servo motors and DC servo motors, coreless motors, etc., which is a high-performance alternative to stepper motors, of which DC servo motors are the most widely used, and NdFeB permanent magnets account for about 45% of DC motor costs.

Rare earth permanent magnet materials industry – robots and rare earth permanent magnet motors

The production capacity of magnetic material companies is expanding rapidly, and robot demand may become a new growth point.

China is the world’s magnetic materials power, high market share, the head enterprises expansion plan is clear, the agency counted up to now the domestic magnetic materials listed companies rare earth NdFeB production capacity and planning, by 2025 the total production capacity or will reach nearly 200,000 tons, compared with 2022 production capacity growth of 63.18%, annual compound growth rate of 17.73%, the future robot downstream demand outbreak or will drive the magnetic material industry to continue to be in short supply, become a new performance growth point of magnetic material enterprises.

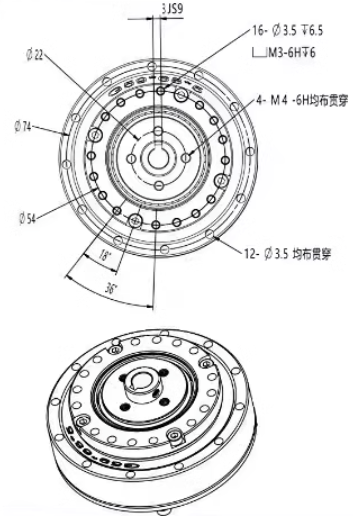

Mechanical arm joint transmission cup size drawing

2. The rare earth permanent magnet industry is expected to usher in new growth

With the support of national policies, the development of the robot industry has entered the fast lane. On June 15, 2023, the General Office of the Shanghai Municipal People’s Government issued the “Shanghai Three-Year Action Plan for Promoting the High-quality Development of the Manufacturing Industry (2023-2025)”, proposing that by 2025, Shanghai will add no less than 20,000 industrial robots, and strive to use 360 industrial robots / 10,000 people, accelerate the innovation and development of humanoid robots and build an intelligent robot terminal brand. On June 28, 2023, the General Office of the Beijing Municipal People’s Government issued the “Beijing Robot Industry Innovation and Development Action Plan (2023-2025)”, proposing that by 2025, the income of the city’s core robot industry will reach more than 30 billion yuan, and the layout of humanoid robots and the consolidation and improvement of four types of advantageous robots in medical health, collaboration, special and logistics will be strengthened. CITIC Securities believes that as the policies of Beijing, Shanghai and other cities continue to increase, the robot industry is expected to enter a new era of rapid development.

High-precision robotic arm joint transmission cup

High-performance NdFeB is the core material of robot servo system, assuming that the price of high-performance NdFeB for robot servo motor in 2025 is 500,000 yuan / ton, and under optimistic expectations, it is expected that the demand for high-performance NdFeB in the global robot industry in 2025 will be 61,000 tons, corresponding to the global high-performance NdFeB market size of 30.5 billion yuan in 2025. With the rapid development of the robot industry, the downstream demand of the rare earth permanent magnet industry is expected to usher in a new growth pole, and the price of rare earths may be supported for a long time, focusing on the strategic allocation value of the rare earth industry chain.

3. Rare earth prices are expected to stabilize, and pay attention to the value of industrial chain allocation

In the medium and long term, according to data from the General Administration of Customs, China’s rare earth permanent magnet exports have continued to grow since 2013, and China’s rare earth permanent magnet exports increased by 8.6% year-on-year to 53,288 tons in 2022, a record high; According to Frost & Sullivan’s forecast (quoted from the Jinli permanent magnet announcement), the output of rare earth permanent magnet materials in China and the world will reach 284,000 tons and 310,000 tons respectively in 2025.

4. Pay attention to the rare earth magnetic material investment opportunities brought by the robot sector

In terms of specific layout, Deppon Securities said that the robot sector ushered in an accelerated rise, and the upstream rare earth permanent magnets may benefit, and then pay attention to the increase in demand for rare earth magnets brought about by the increase in the robot sector.

Humanoid robot joint module

It is expected that the market demand in the future market may be boosted by the robot industry, and it is necessary to pay close attention to the changes in the downstream market, focusing on magnetic material companies.

Rare earth permanent magnet materials

Focus on companies dedicated to the development, production and sales of high-performance permanent magnet materials.

The important role of servo motors in robots

Servo motors play a vital role in robots, mainly including the following aspects:

Joint control: Collaborative robots usually consist of multiple joints, each of which requires the use of servo motors to control its movement, enabling the robot to accurately perform various tasks.

Operational accuracy: Because servo motors can provide high-precision motion control, they are often used in applications that require high-precision operation, such as assembly or manufacturing.

Robotic arm – manufacturer of robotic claws

Robot arm control: Servo motors are also commonly used in robotic arms, which need to be able to move and rotate precisely to be able to perform various tasks, such as handling items or performing assembly.

Servo motors therefore play a key role in the motion control of robots and the precise execution of tasks.

Servo system is used to accurately follow or reproduce a process of feedback control system, with high reliability and stability of high-performance NdFeB permanent magnet material is the core material to build robot servo system, can make the core components to achieve small and light weight, rapid response, and have a strong short-term overload capacity. In 2020, servo systems, precision reducers and controllers accounted for 25%, 35% and 10% of the cost of industrial robots, respectively, with the rapid development of the robot industry, the demand for high-performance NdFeB is expected to be supported.

Some investors asked on the investor interactive platform: Will the robot move, does it use the company’s motor rotor and stator?

Tongda Power(002576. SZ) said on the investor interactive platform on July 11 that the servo motor core produced by the company can be applied to the field of robotics.

Tongda Power: The servo motor core produced by the company can be used in the field of robotics.

China Jinli Permanent Magnet: In the first quarter of 2023, the company’s revenue in the field of robotics and industrial servo motors was 58 million yuan.

Jinli Permanent Magnet pointed out in a recent institutional survey that the company’s revenue in the field of robotics and industrial servo motors in the first quarter of 2023 was 58 million yuan, a year-on-year increase

34% long. The company has been very concerned about the development of the robot industry, has been deeply cultivated in the field of robots and industrial servo motors for many years, with deep technical accumulation, as well as high-quality customer resources, the company is also confident to grasp the future market opportunities.