Since the servo motor is a high-precision motor, it can be controlled and used by a communication protocol and can be equipped with an encoder for precise positioning. It is a commonly used motor in precision automation equipment, CNC machine tools and industrial robots.

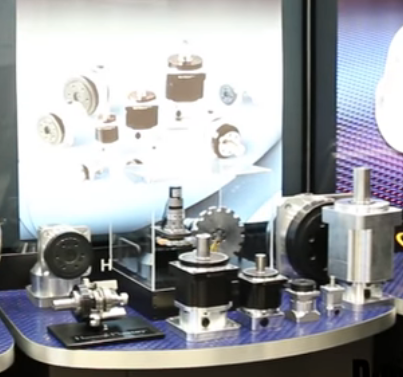

Robot articulated arm reducer - harmonic transmission equipment

The robot system is a whole composed of the robot, the working object and the environment, including four parts: mechanical system, drive system, control system and perception system. Robot is an automated machine, which has some intelligent abilities similar to humans or creatures, such as perception, planning, action and coordination, and is an automated machine with high flexibility. The robot system is composed of the robot, the working object and the environment, including four parts: mechanical system, drive system, control system and perception system.

1. What kind of structure is the joint of the robot? What does it do?

At the joints of the robot, the classic way is a servo motor (externally) with a servo planetary reducer to support the force generated by the left and right axes at the rear. Simply put, it is to provide a force in the control range to allow the rest of the axes to move.

https://www.youtube.com/watch?v=kYMmQ45kki4

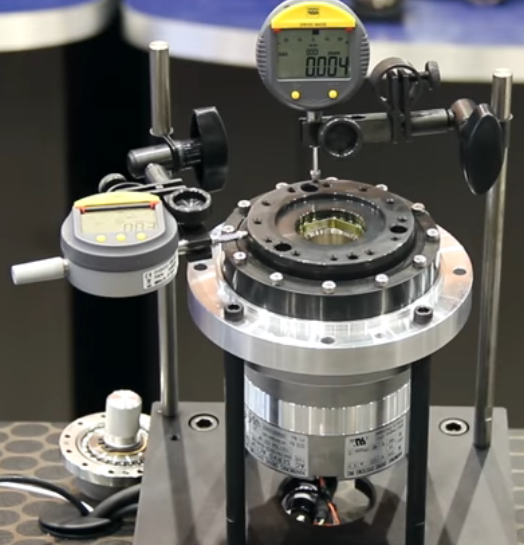

Installation of cup type harmonic drive with servo motor - Video tutorial for installing a servo motor

This results in large torques at the joints of the robot and the need for servo planetary gearboxes to provide higher resolution and closing accuracy.

2. The problem of traditional robot joint structure.

(1) Torque problem:

Here's a tricky problem. How to get a lot of torque? Is it to directly increase the current of the servo motor?

Robot articulated arm reducer

That kind of motor will not work for a few days. Therefore, a servo planetary reducer is required, and through a reduction ratio of 50:1, a 100mNm can be obtained by 5Nm through the reducer.

(2) Control accuracy.

installation of cup type harmonic drive with servo motor

Although the servo motor can control the position, speed and angle through the encoder, the 22-bit encoder commonly used at present is still not as many types and stable and reliable as the servo planetary reducer.