Spherical splines are widely used and used, such as machine tools, ball screw motors, automobiles, aircraft and other machinery; The other is the involute spline shaft, which is mainly used in those links with high centering accuracy, large load and large size; The third type is triangular splines, which are used to join thin-walled parts.

When should you use a ball spline?

Ball spline is a rolling guide assembly, mainly composed of nut, screw, steel ball and retainer, through the steel ball between the nut and the screw for infinite circulation rolling, so that the nut can move along the screw with high precision linear movement.

Splines of balls

ball spline vs ball screw - difference between ground ball screw and rolled ball screw

NB ball spline is a linear motion mechanism that uses ball rolling motion.

Since it can load radial load and torque at the same time, it is used in a wide range of fields such as conveyors and robots.

Features features

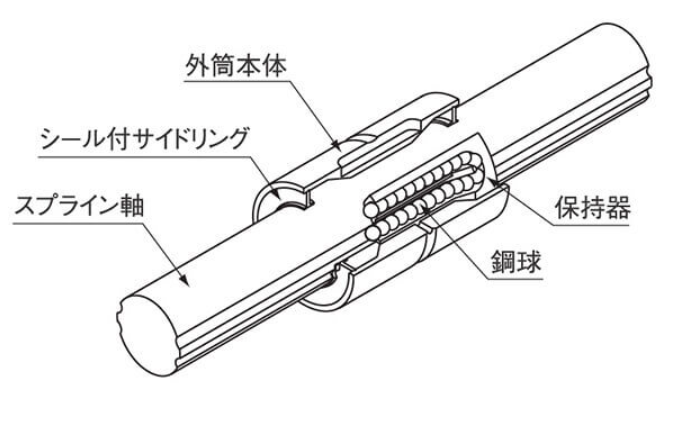

The NB ball spline consists of a splined shaft with a drive groove and an outer cylinder. The spline outer barrel contains a cage, side rings and steel balls, designed and manufactured to slide smoothly.

· Large carrying capacity and long life

difference between ground ball screw and rolled ball screw

Because the track surface is finely ground into an R shape close to the diameter of the steel ball, the contact area of the steel ball is large, the bearing capacity is high and the life is long.

· Abundant variety

In NB, the nominal diameter of the splined shaft can be from 4 to 100, and the outer cylinder shape can be cylindrical, flange, block, depending on the model, it can also support stainless steel, and can be selected according to the application.

· High-precision torque transmission is possible

https://www.youtube.com/watch?v=4XyXAmw-nwQ

Ball spline vs ball screw - difference between ground ball screw and rolled ball screw —— motorforum.rfidepc.com

Since the shaft and the transfer groove of the outer cylinder form an appropriate contact angle relative to the steel ball, a large torque can be transmitted. In addition, by applying prepressure to zero clearance in the direction of rotation, rigidity can be improved and correct rotation positioning can be achieved.

· Easy to add

Since the NB ball spline has the shape of a circular shaft with a transfer groove, it is easy to machine to the shaft end for installation.

· High-speed movement and high-speed rotation are possible.

The outer cylinder is compact and well balanced, showing sufficient performance even in high-speed motion and high-speed rotary movement.

ball spline vs ball screw - difference between ground ball screw and rolled ball screw - ball screw application examples