Mechanical design is often inseparable from their own experience, the accumulation of experience can learn a lot from books, but it is difficult to leave a deep impression in the mind, for the experience of others, they do not have a certain foundation, to understand and absorb is really not easy.

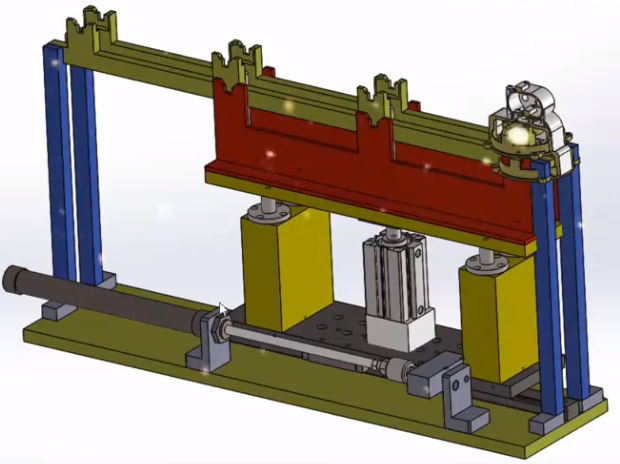

Servo system engineering machinery design

Ordinary mechanical design and mechanical engineer is far from a level, the title of mechanical engineer is not just drawing, from the scheme to the prototype can be completed independently, with rich design experience, which is actually quite difficult.

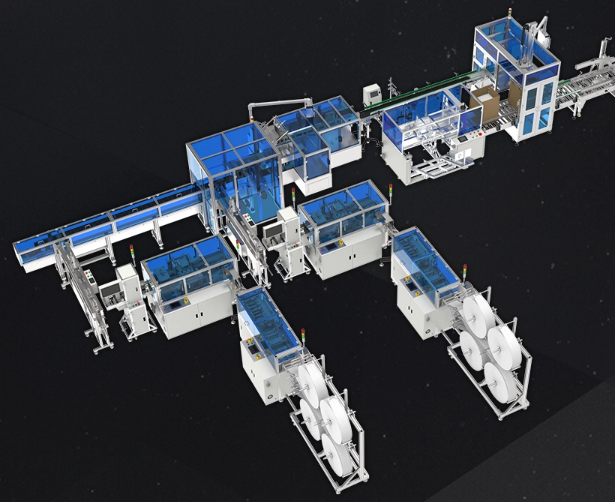

Stepper motor for mask machine

How to become a good mechanical engineer?

1. Mechanical structure design ability

In order to become a good mechanical designer, good structural design ability is the foundation of his professional and technical ability. Mechanical design has the characteristics of "high trial and error cost, few growth opportunities, high practical experience requirements, and low success rate".

In order to improve their design capabilities, first of all, they need to be skilled and correct in the use of typical mechanical structure types, especially the advantages and disadvantages of each mechanical mechanism, commonly used structural methods, methods, etc., can be readily used when the design needs, such as gear transmission, chain transmission, cam transmission, pulley transmission (flat belt, round belt, V-belt, etc.), connecting rod transmission; The second is to improve the knowledge and cultivation of various aspects of machinery, be familiar with various basic characteristics and variants, and understand the historical development and adoption of mechanical mechanisms, structural methods and methods of various equipment.

2. Theoretical basis of mechanics

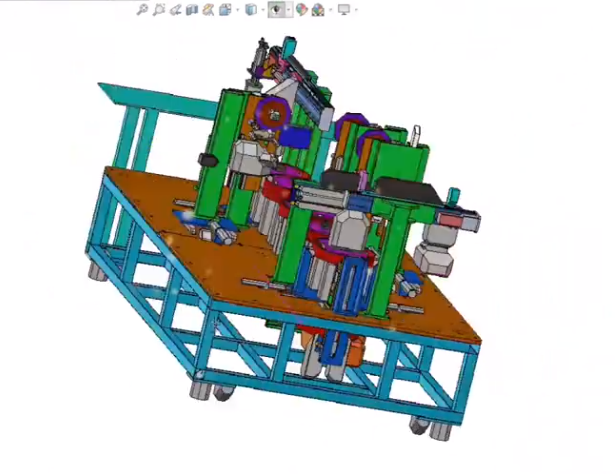

mechanical engineer

A good mechanical designer must also be a mechanical engineer and materials engineer, but the opposite is not necessarily true. This is the basic condition to ensure product design, engineering mechanics, material mechanics is a compulsory course in the university, which is also a very important professional threshold.

As a designer, you need to be familiar with the mechanical properties of commonly used metal materials, the thermal processing of materials, heat treatment processes and their selection, etc., understand the types and applications of common engineering plastics, special ceramics, optical fibers and nanomaterials, and even their color and price, in order to correctly select materials and appropriate heat treatment methods in the design process.

3. Processing cognitive ability

In the early stage of design, in addition to the selection of parts, you also need to consider the feasibility of processing, cycle, quality and a series of other problems, if you lack this ability, it is difficult for you to really be a mechanical design engineer.

In order to improve the cognitive ability of processing, it is necessary to be familiar with the basic technical content, methods and characteristics of mechanical manufacturing processes such as casting, welding, cutting (grinding), special processing, surface coating treatment and so on. Understand the principles and knowledge of production line design and workshop layout, and strengthen the understanding of new technologies and new processes.

4. Assemble cognitive ability

The designed product is also undesirable if it cannot be assembled, or if the assembly is complex.

Woodworking Engraving Machine - High Precision Furniture Relief Engraving Machine - Screen Wooden Door Carving Hollow Equipment

5. Parts selection and supply chain relationship

We design products where not everything needs to be started from scratch, and many times it is an organic combination of various functional parts. Take the robot body, there are self-designed body castings, machining parts, and mature functional parts that are finalized on the market, such as motors, reducers, gears and so on.

6. Drawing skills

Drawing is an essential skill for mechanical designers to eat.

Now that the era of hand-drawn drawings has passed, the design is more three-dimensional. Therefore, learning a 3D software is a must. There are many modeling software on the market today: UG, solidworks, pro/e, catia, inventor, etc.

Of course, the proficiency here is not like our resume, drawing a few parts, or designing a few products, it is called proficiency in 3D drawing software.

Woodworking Engraving Machine - Screen Wooden Door Carving Hollow Equipment

7. Drawing management

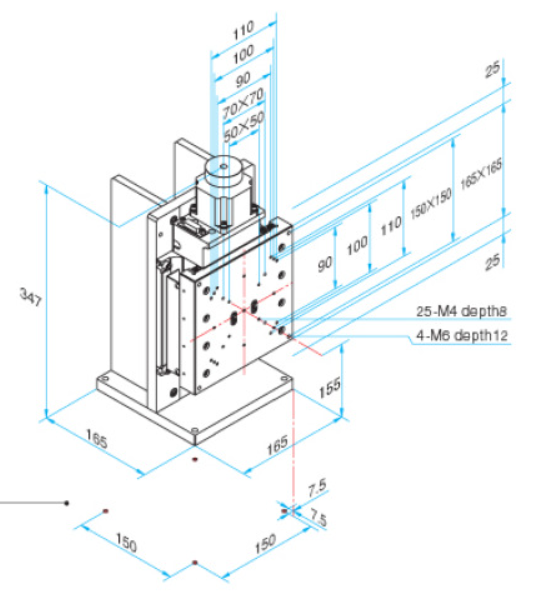

Japan Sigma precision automatic platform - five-phase stepper motor mechanical structure design

No matter what software you use to do CAD design, it is recommended that you do a good job of personal drawing management.